در قلب صنایع شیمیایی هلند - از پالایشگاههای ... بندر روتردام به کملوت در شهرک صنعتی گلین، کنترل انتشار گازهای گلخانهای با یک چالش بسیار مهم روبرو است: چگونه گازهای خروجی «غیرپایدار» از شیرهای اطمینان فشار (PSV/SRV) و دریچههای اضطراری ستون تقطیر را مدیریت کنیم.

برخلاف جریانهای هوای پایدار موجود در کارگاههای نقاشی، این جریانهای خروجی با ویژگیهای زیر مشخص میشوند: انفجارهای آنی با غلظت بالا و نوسانات شدید جریانبه عنوان هلندی Activiteitenbesluit milieubeheer (فرمان فعالیتها) نظارت بر انتشار گازهای ناپایدار را تشدید میکند، اکسیدکنندههای حرارتی احیاکننده (RTO) به راهحل نهایی برای شرکتهای شیمیایی تبدیل شدهاند تا ایمنی عملیاتی را با رعایت الزامات زیستمحیطی متعادل کنند.

RTO برای دریچههای تخلیه ایمنی چیست؟

۱. RTO چیست؟

RTO مخفف اکسیدکننده حرارتی احیاکننده است. این روش از اکسیداسیون در دمای بالا (معمولاً ۸۱۵ تا ۹۸۰ درجه سانتیگراد) برای تبدیل ترکیبات آلی فرار (VOCs) به $CO_2$ و $H_2O$ استفاده میکند. مزیت اصلی آن در بازیابی حرارتی واسطه سرامیکی است که به راندمان بازیابی حرارتی ۹۵۱TP3T-97% دست مییابد.

۲. برای کدام انتشارات راکتور مناسب است؟

این دستگاه به طور خاص برای بخشهای پتروشیمی، مواد شیمیایی خالص و داروسازی طراحی شده است تا گازهای آلی پیچیده و با غلظت بالا تولید شده توسط ... فشار بیش از حد راکتور، اختلالات فرآیند یا تخلیه اضطراری از بالای ستونهای تقطیر.

۳. چرا تصفیه گاز خروجی سوپاپ اطمینان بسیار حیاتی است؟

فلرها یا اسکرابرهای سنتی اغلب با افزایش ناگهانی بار VOC دست و پنجه نرم میکنند. یک سیستم RTO با کارایی بالا نه تنها تضمین میکند که راندمان حذف تخریب (DRE) بیش از 99% بلکه با به حداقل رساندن مصرف سوخت کمکی، ردپای کربن را نیز به میزان قابل توجهی کاهش میدهد.

پارامترهای فنی اصلی RTO برای سناریوهای امدادی

یک RTO که گاز زائد راکتور را تصفیه میکند، هرگز یک واحد «استاندارد» نیست. برای مدیریت نوسانات شدید فرآیند، پارامترهای فنی آن باید به دقت مهندسی شوند.

جدول پارامترهای فنی کلیدی

| معیار فنی | محدوده پارامتر | تأثیر بر ایمنی و عملکرد | استاندارد مرجع |

|---|---|---|---|

| دمای عملیاتی | ۸۱۵ تا ۹۸۰ درجه سانتیگراد | تضمین تخریب کامل ترمودینامیکی هیدروکربنهای با غلظت بالا | EPA 452/B-02-001 |

| تخریب ترکیبات آلی فرار (VOC) (DRE) | ≥ 99% | تضمین انطباق حتی در اوج حوادث امدادی | اتحادیه اروپا IED 2010/75/EU |

| بازیابی حرارتی (TER) | 95% – 97% | خودکفایی انرژی را در دورههای کمباری تعیین میکند | گزارشهای انرژی صنعتی |

| زمان اقامت | ۰.۵ تا ۱.۰ ثانیه | تضمین میکند که مولکولهای پیچیده در منطقه داغ کاملاً اکسید میشوند. | مدلسازی سینتیکی |

| زمان پاسخ LEL | <1.0 ثانیه | فعال شدن فوری سیستم محافظت پس از تشخیص غلظتهای بالا | استانداردهای SIS |

| مقاومت سیستم (ΔP) | ۲۵۰۰ تا ۴۵۰۰ پاسکال | بر انتخاب فن و فشار برگشتی در هنگام امدادرسانی اضطراری تأثیر میگذارد | دینامیک سیالات کالک |

| میزان نشتی شیر | <0.1% | از بایپس شدن گاز تصفیه نشده به دودکش جلوگیری میکند | شیرهای پاپت بدون نشتی |

محرکهای عملکرد بحرانی:

- راندمان تخریب VOCدر طول انفجارهای ناگهانی از شیرهای اطمینان، RTO باید مشخصات احتراق پایدار را حفظ کند. یک سیستم با کیفیت بالا نیاز به یک سیستم قوی دارد. نسبت خاموشی مشعل برای جلوگیری از نوسانات دما.

- بازیابی انرژی حرارتیواسطههای سرامیکی کارآمد، دمای کوره را در طول وقفههای فرآیند حفظ میکنند، از مصرف نامنظم گاز طبیعی جلوگیری کرده و هزینههای عملیاتی را تثبیت میکنند.

ویژگیهای سناریو: مزایا و محدودیتها

تحلیل سناریو: انتشار گازهای گلخانهای در حالت غیرپایدار

خروجی از راکتورها و ستونهای تقطیر اغلب "متناوب، با حجم بالا و غلظت بسیار بالااین امر مستلزم مقاومت استثنایی در برابر ضربه از سوی تجهیزات کاهش دهنده است.

- مزایا:

- بهرهوری انرژی استثناییدر طول رویدادهای اوج VOC، سیستم میتواند وارد حالت «خودگرمایی» شود که اغلب گرمای اضافی تولید میکند که قابل بازیابی است.

- پایداریدر مقایسه با فلرهای روباز، RTOها به طور چشمگیری ردپای کربن و انتشار گازهای گلخانهای را کاهش میدهند، که با هلندیها همسو است. کلیما تاکورد (توافقنامه آب و هوا).

- چالشها و محدودیتها:

- خطرات بازگشت به گذشته/انفجارغلظتهای بالا خطرات آتشسوزی را ایجاد میکنند. راه حل: باید شامل مخازن بافر، فنهای رقیقسازی و تشخیص فوقالعاده سریع LEL باشد.

- خوردگیاگر هالوژنها (کلر، برم) وجود داشته باشند، سرامیکهای مقاوم در برابر اسید مخصوص و پوششهای داخلی مورد نیاز است.

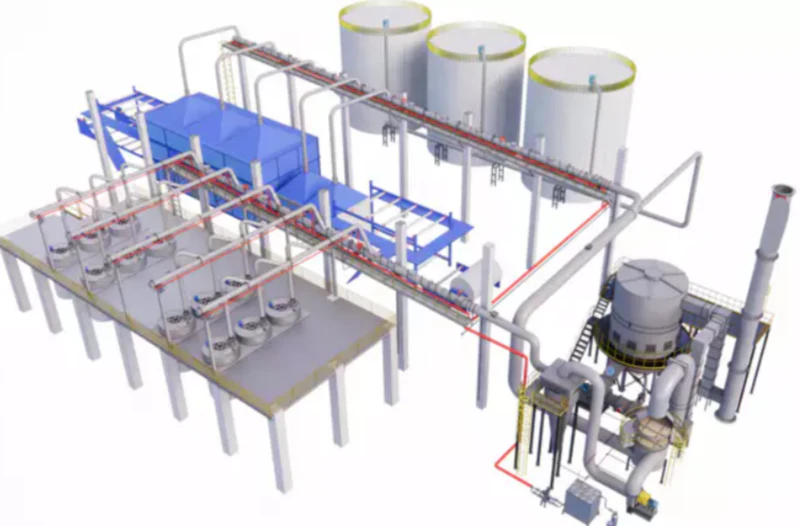

اجزای سیستم RTO و توصیههای اکوسیستم

پایداری RTO از نظر شیمیایی به اجزای «اکوسیستم» با کیفیت بالا بستگی دارد:

- رسانه تبادل حرارت سرامیکیسرامیکهای مولایت لانه زنبوری یا زینی شکل برای سطح تماس بالا و افت فشار پایین توصیه میشوند.

- شیرهای پاپت با سوئیچینگ سریعزمانهای پاسخ در حد میلیثانیه برای مدیریت موج ناگهانی یک رویداد امدادی حیاتی هستند.

- سیستم بای پس گاز داغ: برای تخلیه انرژی حرارتی اضافی به دیگ بخار گرمایش اتلافی، زمانی که غلظت VOC از نقطه خودگرمایی فراتر میرود، ضروری است.

- نظارت بر حد پایین انفجار (LEL)آشکارسازهای مادون قرمز یا پارامغناطیس با دو افزونگی برای فعالسازیهای ایمنی در سطح میلیثانیه توصیه میشوند.

تحلیل مقایسه برندهای RTO اصلی

| برند | قدرت هسته | کارایی (TER/DRE) | تمرکز صنعت | توصیه |

|---|---|---|---|---|

| دور (اکوپور) | مهندسی آلمانی؛ پایداری مطلق برای کاربردهای شیمیایی پرخطر. | 97% / 99.9% | پتروشیمی، پالایشگاههای بزرگ | بهترین گزینه برای پروژههای با بودجه بالا که در آنها ایمنی اولویت #1 است. |

| آنگیل | دههها تجربه در کار با اگزوزهای هالوژنه خورنده. | 95% / 99% | مواد شیمیایی مرغوب، آفتکشها | ایدهآل برای جریانهای شیمیایی پیچیده و خورنده. |

| قدرت همیشگی | ادغام قویمتخصصان سیستمهای بازیابی RTO+ نصبشده روی شاسی. | 96% / 99.5% | داروسازی، کارخانههای شیمیایی متوسط | بهترین برای هزینه-عملکرد و تحویل کلید در دست. |

| تایکیشا | کنترل دقیق انرژی و انتشار بسیار کم $NO_x$. | 95% / 99% | مجتمع خودرو و شیمی | بهترین گزینه برای سناریوهایی که نیاز به استفاده از گرمای ثانویه پیچیده دارند. |

انطباق با بازار جهانی و محلی (سئو محلی هلند)

در هلند، آی ال تی (بازرسی محیط زیست انسانی و حمل و نقل) ترکیبات آلی فرار (VOCs) را تا تک تک نقاط امدادرسانی اضطراری رصد میکند.

- بازار هلند:

- هابها: خوشه های شیمیایی در روتردام، ترنوزن و گلین.

- مقررات: اتحادیه اروپا و هلند نِ آر استانداردها

- مشوقهاسرمایهگذاریهای RTO واجد شرایط هستند EIA (Energie-investeringsaftrek) اعتبار مالیاتی، که به طور قابل توجهی هزینههای سرمایهای (CAPEX) را کاهش میدهد.

- روندهای جهانی:

- ایالات متحده آمریکاانطباق دقیق با روش 25A سازمان حفاظت محیط زیست آمریکا (EPA) برای ثبت رویدادهای SRV.

- چین: GB 37822-2019، RTOها را به یک «الزام قطعی» برای مدیریت نوسانات فرآیند شیمیایی تبدیل میکند.

تجربه میدانی و مطالعات موردی

بینش متخصص: مدیریت اضطراب «آتشسوزی ناگهانی»

در طول یک پروژه شیمیایی در نورد-برابانتمن شخصاً بر راهاندازی اگزوز رآکتور با غلظت بالا نظارت داشتم.

- چالشغلظت بلافاصله پس از باز شدن شیر به ۴۵۱TP3T LEL افزایش یافت.

- راه حلما یک را پیادهسازی کردیم منطق رقیقسازی سهگانه و یک کره بافر بالادست اضافه کرد.

- نکته کلیدیتصفیه گاز کمکی ربطی به «سوزاندن» ندارد؛ بلکه مربوط به «متعادلسازی» است - استفاده از الگوریتمهای تطبیقی مبتنی بر هوش مصنوعی برای پیشبینی نوسانات بار، تنها راه تضمین عملکرد ایمن و بلندمدت است.

مطالعه موردی: یک کارخانه تولید مواد شیمیایی مرغوب هلندی

- پیشینهگاز کمکی ستون تقطیر حاوی مقادیر زیادی دیکلرومتان بود؛ جذب سنتی ناموفق بود.

- راه حل: RTO سه محفظهای مقاوم در برابر اسید + بویلر بازیابی حرارت پاییندست.

- نتیجهمیزان VOC DRE در ۹۹.۷۱TP3T ثابت ماند و بخار بازیافتی ۳۰۱TP3T از نیاز حرارتی کارگاه را برآورده کرد.

روندهای آینده: مرز بعدی

- RTO + جذب کربن (CCUS)هدایت مجدد $CO_2$ تصفیهشده از اگزوزهای RTO به گلخانههای هلندی، تبدیل جریان ضایعات به یک محصول با ارزش افزوده.

- مشعلهای آماده برای هیدروژن: گذار به سوختهای کمکی بدون کربن برای حذف ردپای کربن ناشی از خود فرآیند کاهش انتشار گازهای گلخانهای.

- نگهداری و تعمیرات پیشبینانه هوش مصنوعیاستفاده از یادگیری ماشین برای تجزیه و تحلیل دادههای حسگر فشار جهت پیشبینی وقایع مربوط به تخلیه شیر، که به RTO اجازه میدهد تا «پیش گرمایش» را انجام داده و تأخیرهای درمان را از بین ببرد.

نتیجهگیریبرای دریچههای تخلیه راکتور و ستون تقطیر، RTO مقاومترین انتخاب تکنولوژیکی است. برای شرکتهای شیمیایی هلندی، این فقط یک چکباکس نظارتی نیست - بلکه یک جزء حیاتی از مدیریت ایمنی فرآیند (PSM) است.

نوشته شده توسط یک متخصص محیط زیست فرآیند. برای مشاوره در مورد هلندی آر تی او برای انتخاب یا درخواستهای یارانه EIA، لطفاً برای مشاوره با ما تماس بگیرید.