HAP

Comprehensive Guidelines for HAPs Treatment in the Netherlands

What is RTO?

Regenerative Thermal Oxidation (RTO) is an advanced air pollution control technology designed to destroy Volatile Organic Compounds (VOCs) and Hazardous Air Pollutants (HAPs) in industrial exhaust gases. This process utilizes high temperatures to oxidize harmful substances, ensuring compliance with environmental regulations such as those set by the EPA and, in the European context, the EU’s Industrial Emissions Directive (IED) as implemented in the Netherlands.

Basic Parameters

What are HAPs?

HAPs are defined by regulatory bodies as pollutants that pose significant health risks. In the context of RTO, gases containing HAPs are classified based on their chemical composition, volatility, and toxicity. Common categories include:

- Organic HAPs: Such as benzene, toluene, and xylene.

- Inorganic HAPs: Including metals like arsenic and mercury.

- Halogenated Compounds: Such as chloroform and vinyl chloride.

RTO systems are particularly effective for treating organic HAPs through thermal decomposition, aligning with stringent Dutch emissions standards.

How Does RTO Manage HAPs?

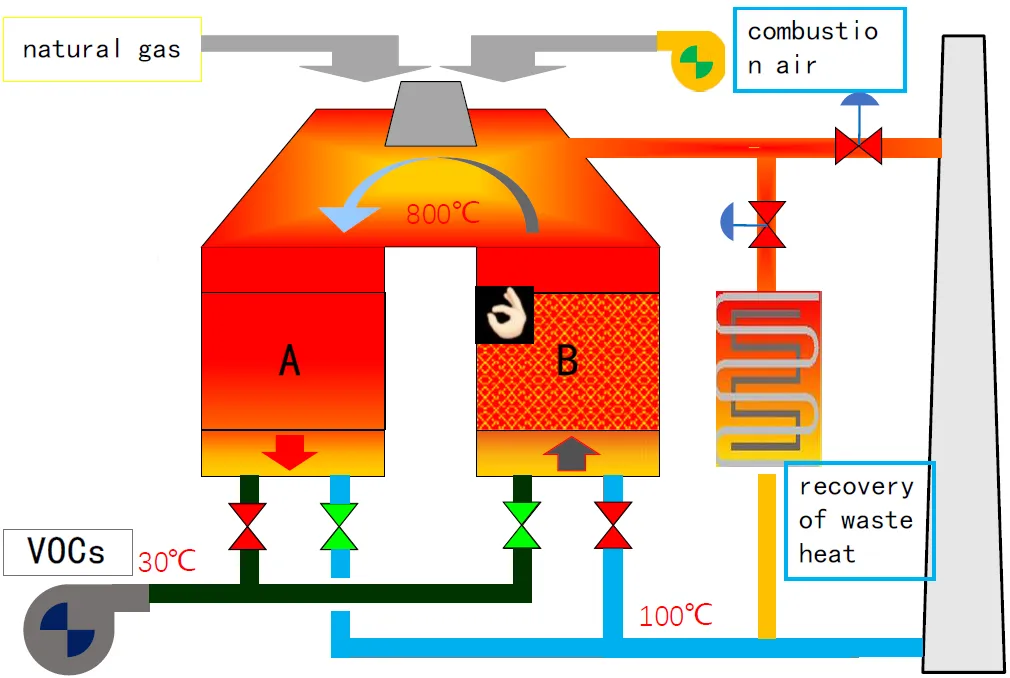

RTO systems typically consist of multiple ceramic media beds used to capture and regenerate heat energy to improve energy efficiency. The specific process is as follows:

- Exhaust Gas Introduction: Industrial exhaust gas containing HAPs is introduced into the RTO unit.

- High-Temperature Oxidation: The exhaust gas is heated to approximately 800–1000°C (or 1500°F), at which temperature, the HAPs undergo oxidative decomposition, generating harmless CO₂ and H₂O.

- Heat Recovery: The purified hot gas passes through the ceramic media beds, which can capture up to 95% of the heat, used to preheat the incoming exhaust gas, thereby reducing energy consumption.

- Emission: The clean gas is discharged through a chimney, complying with environmental regulations.

This process ensures that the HAP destruction efficiency typically exceeds 99%, making it suitable for treating high-volume, low-concentration exhaust gases.

Advantages of RTO in HAPs Governance

High Efficiency

RTO is specifically designed to destroy volatile organic compounds (VOCs) and HAPs, and is suitable for industries such as chemical, printing, and pharmaceutical.

Energy-Saving Design

The regenerative heat recovery mechanism enables the system to achieve a thermal efficiency of up to 95%, significantly reducing operating costs.

Environmental Compliance

It can effectively reduce HAP emissions and help businesses meet stringent air quality standards.

Expertise & Qualifications

Application Industries

Industrie de l'impression

Coatings Industry