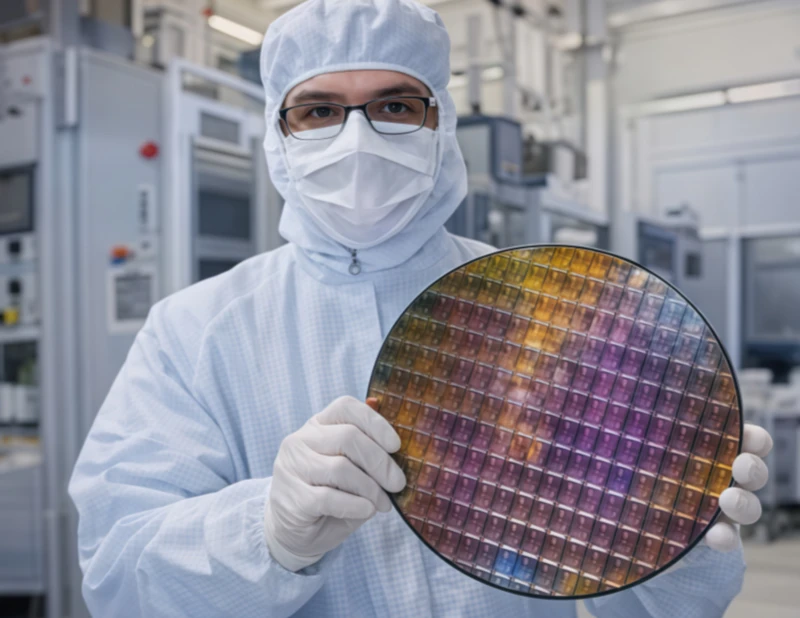

ヨーロッパのイノベーションハブの中心地であるオランダは、極端紫外線リソグラフィーシステムのパイオニアであるASMLなどの企業によって牽引され、半導体技術の世界的リーダーとなっています。ウェーハパターニングとフォトレジスト塗布に重点を置くこの精密産業は、特定の排ガスを発生させ、クリーンルームの完全性と環境への責任を維持するために、確実な除去が求められます。再生熱酸化装置(RTO)は、フォトレジストコーティングに使用されるプロピレングリコールモノメチルエーテルアセテートなどの溶剤から発生する揮発性有機化合物を処理する上で、不可欠なツールとなっています。これらのシステムは、汚染物質を効果的に破壊するだけでなく、熱を回収することで、ASMLの施設が盛んに稼働している北ブラバント州のようなエネルギー意識の高い地域における運用コストを最小限に抑えます。

リソグラフィー工程では、ウェハに感光性材料を塗布し、パターン化された光を照射して画像を現像します。これらの工程では、有機溶剤の蒸気が蒸発し、低濃度ながらも大量の排気ガスが発生します。持続可能性が企業文化に深く根ざしたオランダの工場では、RTO(Return to Technology:遠隔技術移転)がシームレスに統合され、欧州グリーンディールなどの枠組みに基づく産業排出量削減への国の取り組みを支えています。近隣のベルギー・フランダース地方では、同様の設備がimecの研究センターを支援しており、ドイツのザクセン州には、国境を越えた排出削減技術の専門知識の共有から恩恵を受けている工場が集まっています。

地域別のフォトリソグラフィーの特徴

欧州以外では、TSMCの巨大な生産ラインを有する台湾などの主要半導体国は、リソグラフィー排気ガスの管理にRTOを活用し、VOCを20 mg/m³未満に制限する厳格な大気質規制を遵守しています。韓国の華城にあるサムスン電子の工場では、同様のガスを処理するために高度なRTO設計を採用しており、高いエネルギー需要に対応するために95%を超える熱回収率を重視しています。米国では、インテルのオレゴン工場がリソグラフィー向けにカスタマイズされたRTOを使用しており、EPA(環境保護庁)の有害大気汚染物質に関する国家排出基準に準拠しています。この基準では、有機有害大気汚染物質(HAP)の分解効率を98%と定めています。

日本の東京エレクトロンとキヤノンの熊本工場は、アジアの製造拠点で一般的に見られる高湿度環境に耐える必要があるリソグラフィー分野におけるRTOの適用を顕著に示しています。中国の上海SMICは、ウェハ処理ガスの処理にRTOを導入し、NMHC排出量を40 mg/m³に制限するGB 37822-2019規格に準拠しています。タワーセミコンダクターの本拠地であるイスラエルは、乾燥気候に適した低メンテナンス設計に重点を置いて、ミグダル・ハエメク工場にRTOを導入しています。

シンガポールのグローバルファウンドリーズ工場は、スペースが限られた都市部のファブ向けにコンパクトなRTOユニットに重点を置いています。一方、マレーシアのクリムにあるシルテラ社は、同国のグリーンテクノロジー・ファイナンシング・スキームによる優遇措置を受け、リソグラフィー廃棄物処理にRTOユニットを活用しています。アイルランドのインテル・リークスリップ・キャンパスは、EUのIED指令に準拠したRTO技術を活用しており、スコットランドのシリコン・グレンなどの近隣の英国施設と共有しています。

フィンランドのオウルで台頭する半導体産業は、北欧の環境政策を参考に、リソグラフィーにおけるRTO統合を模索しています。オーストリアのプレムシュテッテンにあるams-OSRAMは、センサーウエハー生産にRTOを採用しています。一方、スペインのカタルーニャ地方の新興拠点は、持続可能なリソグラフィー削減のためにオランダのモデルを参考にしています。ポーランドの成長著しいワルシャワのエレクトロニクス部門は、EUのグリーンテクノロジー統合基金の影響を受け、RTOを導入しています。

チェコ共和国のロジュノフ・ポド・ラドホシュチェムにあるオン・セミコンダクターは、ウエハー製造工場の排気ガス処理にRTOを採用しています。ポルトガルのヴィラ・ド・コンデにあるナニウムはパッケージングに特化していますが、リソグラフィーガス処理のニーズは共通しています。スイスのジュネーブにあるSTマイクロエレクトロニクスは精密なRTO制御を採用しており、スウェーデンのキスタにあるエリクソンは通信用チップ製造へのRTO導入を検討しています。

デンマークのコペンハーゲンにおける半導体産業の小規模な活動は、ドイツとオランダの専門知識との近接性から恩恵を受けており、RTOはリソグラフィーの拡張に役立っています。ノルウェーのクリスチャンサンにあるREC Siliconは、ポリシリコン前駆体を扱っており、関連ガスにはRTOを利用しています。ルクセンブルクのエシュ=シュル=アルゼットにある小規模な研究開発施設は、RTOの展開に関してベルギーとフランスの規制の整合性を活用しています。

フランスのクロルにあるSTマイクロエレクトロニクスは、VOC排出量を110 mg/m³未満に抑えるという国の法令に準拠したリソグラフィー用RTOを導入しています。英国のカーディフにある複合半導体応用カタパルトは、環境庁の許可を得て、高度なウエハプロセスにRTOを使用しています。

RTOの技術的パラメータ

このような背景から、当社のRTOシステムは、フォトレジストのスピンコーティングおよび現像段階から排出される排気ガスに微量の溶剤が含まれるという、前工程リソグラフィ特有の要求に応えるよう設計されています。これらの溶剤は、工場内の空気質を損なうことなく酸化する必要があります。標準的な構成では、10,000~50,000 m³/hの空気を処理し、乳酸エチルやシクロペンタノンなどのVOCを99%以上分解します。

ウェーハ リソグラフィ シナリオにおける RTO の主な技術的パラメータは次のとおりです。

| パラメータ | 値/範囲 |

|---|---|

| 熱効率(TER) | 95-98% |

| VOC破壊除去効率(DRE) | >99% |

| 動作温度 | 760~850℃ |

| 滞在時間 | 0.5~1.0秒 |

| 風量 | 5,000~100,000 m³/時 |

| 圧力降下 | 100~300 Pa |

| 熱回収媒体 | 構造化セラミックハニカム |

| バルブスイッチングサイクル | 60~120秒 |

| 漏洩率 | <0.5% |

| 補助燃料消費量 | 0~50 Nm³/h 天然ガス(VOC 2 g/m³以上で自立) |

| 消費電力 | サイズに応じて50~200kW |

| 構造材料 | 耐腐食コーティングを施した304/316ステンレス鋼 |

| NOx排出量 | 低NOxバーナーで<50 mg/Nm³ |

| CO排出量 | <100 mg/Nm³ |

| 粒子状物質制御 | サブミクロン粒子用のプレフィルターを内蔵 |

| 湿度耐性 | 除湿オプションで最大80% RH |

| ターンダウン比率 | 5:1 |

| フットプリント | 収容人数に応じて10~50㎡ |

| 重さ | 5~20トン |

| インストール時間 | 4~6週間 |

| メンテナンス間隔 | 毎年検査、5~7年ごとのメディア交換 |

| 安全インターロック | LEL監視、火炎防止装置、緊急バイパス |

| 制御システム | SCADA統合型PLC |

| 騒音レベル | <85 dB(A) |

| エネルギー回収オプション | 熱風または蒸気の発生 |

| コンプライアンス認証 | CE、ATEX、UL |

| 費用範囲 | 規模に応じて50万~200万ユーロ |

| ライフサイクル | 15~20年 |

これらのパラメータにより、ダウンタイムが大きなコストとなるリソグラフィワークフローにRTOがシームレスに適合することが保証されます。例えば、300mmウェーハを処理するオランダの工場では、RTOによって排気中のVOCレベルをppm未満に維持し、超クリーン環境における汚染を防止しています。

前工程リソグラフィー工程では、クリーンルーム排気からのVOC濃度が極めて低く(通常0.1~1 g/m³)、NOxなどの二次汚染物質を生成しない高効率酸化が求められます。リンス工程では湿度が高くなるため、RTOベッドでの結露を防ぐため、強力な除湿が必要です。ウェーハアライメントを乱す可能性のある圧力変動を回避するために、精密な制御が不可欠です。

世界のRTOアプリケーションとトレンド

ファブ設備の設置に携わったあるエンジニアは、個人的な経験から、アイントホーフェンでのプロジェクトを思い出します。このプロジェクトでは、RTOを導入することで年間VOC排出量を95%削減し、新たな許可なしに工場を拡張することができました。ベルギーのルーヴェンでの別のケースでは、このシステムで30%の暖房コストを相殺するのに十分な熱を回収し、寒冷地における実用的なメリットを実証しました。

事例は数多くあります。台湾の新竹サイエンスパークでは、RTOが5nmノード向けリソグラフィーガスを取り扱い、排出量を10mg/m³未満に抑えています。韓国の平沢にあるファブでは、カスタムメイドの低NOxバーナーを用いてEUVリソグラフィーにRTOを使用しています。米国アリゾナ州の拠点では、ArF液浸リソグラフィーにRTOを採用しており、地域の大気汚染規制に準拠しています。

広島にある日本の施設では、現像工程で発生する酸性ガスを除去するためのスクラバーとRTOを統合しています。北京にある中国の工場では、国家基準を満たすDUVリソグラフィーにRTOを使用しています。イスラエルのキルヤット・ガトにある工場では、特殊ウェーハにRTOを適用しています。

シンガポールのジュロンにあるクリーンルームにはコンパクトなRTOが備えられています。マレーシアのバヤンレパスにある施設では、リソグラフィーの排気を効率的に処理しています。アイルランドのダブリンにある工場では、エネルギーをリサイクルするRTOが使用されています。

フィンランドのエスポーにある研究開発センターは、次世代リソグラフィー向けのRTO(Return to Tolerance:再処理工場)を研究しています。オーストリアのフィラッハにある工場は、パワー半導体向けにRTOを導入しています。スペインのバルセロナにある施設は、費用対効果の高い廃棄物処理に重点を置いています。

ポーランドのヴロツワフにある新興ハブはRTOを導入しています。チェコのブルノにある拠点はセンサー用にRTOを使用しています。ポルトガルのポルトにある工場は電子機器向けに統合されています。

スイスのヌーシャテルにある工場は、精密なRTO制御に重点を置いています。スウェーデンのストックホルムにある拠点は通信用チップを製造しています。ノルウェーのオスロにある施設は、シリコンカーバイドを使用しています。

オールボーにあるデンマークの研究開発部門は、オランダの専門知識を活用しています。これらの事例は、世界中のリソグラフィー分野におけるRTOの汎用性を示しています。

主要部品には、ガス切替用のポペットバルブがあり、適切なシールを使用すれば10年以上の耐久性があります。コーディエライトまたはムライト製のセラミック媒体ベッドは、高い熱容量と低い圧力損失を実現し、5年ごとに交換する必要があります。バーナーは、多くの場合低NOxタイプで、安定した燃焼を実現します。

ガスケットやセンサーなどの摩耗しやすい部品は四半期ごとに点検が必要です。バルブの駆動モーターは堅牢で冗長性を備えています。エネルギーを回収する熱交換器は耐腐食性を高めるためにステンレス鋼で作られています。

RTOの将来とリソグラフィーの革新

ブランドを比較すると、Dürrのようなシステムは、リソグラフィーに適した堅牢な設計を備えており、多くの場合、スクラバーが内蔵されています。Anguilは、さまざまなガス負荷に対応する柔軟な構成を提供しています。(注:すべてのメーカー名と部品番号は参考用です。EVER-POWERは独立系メーカーです。)当社の製品は、効率性ではこれらに匹敵しますが、NOx制御を強化して50 mg/m³未満の制限値を満たすなど、オランダの規制に合わせてカスタマイズされています。

革新的な発想を加え、AIを予測メンテナンスに統合することで、リソグラフィー残渣によるベッドファウリングを予測し、寿命を20%延ばすことができます。RTO-RCOハイブリッドシステムにより、オランダの穏やかな冬には温度を下げることで省エネを実現できます。排出量追跡のためのブロックチェーンは、透明性のあるコンプライアンス報告を確実にし、アムステルダムのテクノロジー業界におけるサステナブル投資家にとって魅力的なものとなっています。

さらに詳しく見てみると、リソグラフィーにおいては、RTOはエッチング工程から発生する微量ハロゲンを除去するためのプラズマスクラバーと組み合わせることができますが、前工程では有機物に重点が置かれています。カスタム断熱材は、風の影響を受けやすいオランダ沿岸部の施設における熱損失を低減します。モジュール設計により、ASMLのような成長中のファブの拡張にも対応できる拡張性が得られます。

運用面では、オランダのエンジニア向けの研修プログラムでは、北海油田の安全プロトコルを参考に、可燃性溶剤の安全な取り扱いを重視しています。費用対効果分析によると、RTOはエネルギー節約と罰金回避により、3~5年で投資を回収できます。

ロッテルダムのチームにカスタムベントをご依頼ください RTO 計画し、実証された信頼性で業務を保護します。