In the Netherlands, from the Leiden Bio Science Park to the pharmaceutical clusters in Oss, the management of Volatile Organic Compounds (VOCs) has become a cornerstone of corporate survival. With the Dutch government’s strict enforcement of the Activiteitenbesluit milieubeheer (Activities Decree on Environmental Management), the Regenerative Thermal Oxidizer (RTO) has emerged as the preferred choice for softgel and injectable manufacturers due to its exceptional energy efficiency and destruction rates.

What is an RTO? (Regenerative Thermal Oxidizer)

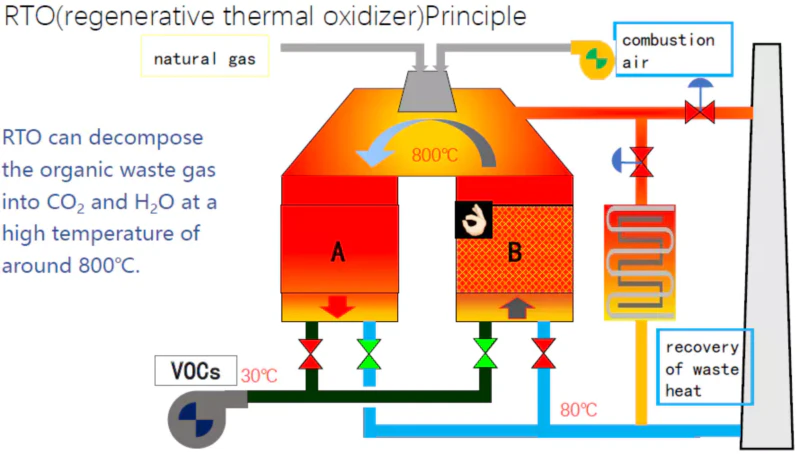

An RTO is an industrial exhaust treatment system designed to oxidatively decompose VOCs at high temperatures (typically between 815°C and 980°C).

Core Working Principle

The RTO operates on a logic of “High-Temperature Oxidation + Efficient Thermal Regeneration.”

- Oxidation Phase: VOCs enter the combustion chamber where a chemical reaction at high heat converts them into harmless Carbon Dioxide ($CO_2$) and water vapor ($H_2O$).

- Regeneration Phase: The RTO utilizes specialized ceramic heat exchange media. As purified high-temperature gas exits, heat is absorbed by the ceramics; as cold raw exhaust enters, the stored heat preheats the incoming gas.

- Cyclic Operation: Through periodic valve switching, the system maintains extremely high thermal efficiency, even achieving “self-sustaining operation” (zero auxiliary fuel) at certain concentrations.

RTO Core Technical Parameters

RTO performance is defined by a multi-dimensional set of metrics. Below is a key parameter table for evaluating an RTO against Dutch NeR standards or US EPA standards.

Key Parameter Benchmark Table

| Technical Metric | Parameter Range | Impact on Performance | Reference Standard |

|---|---|---|---|

| Operating Temp | 815 – 980°C (1500 – 1800°F) | Determines thermodynamic destruction integrity | EPA 452/B-02-001 |

| VOC Destruction Efficiency (DRE) | ≥ 99% (Up to 99.9%) | Ensures emissions stay below 20mg/m³ | EU IED 2010/75/EU |

| Thermal Energy Recovery (TER) | 95% – 97% | Directly impacts natural gas consumption | Energy Efficiency Whitepapers |

| Gas Residence Time | 0.5 – 1.0 Seconds | Ensures full reaction in the high-temp zone | Kinetic Simulations |

| Processing Capacity | 2,000 – 80,000+ scfm | Physical limit of system throughput | Engineering Specs |

| System Pressure Drop (ΔP) | 2500 – 4500 Pa | Affects main fan power consumption | Fluid Dynamics |

| Valve Leakage Rate | < 0.1% | Prevents untreated gas bypass | Zero-leak Poppet Design |

Parameter Deep Dive

- High-Temperature Thermal Oxidizer VOC Efficiency: For pharmaceutical solvents like Isopropanol or Ethanol, a removal rate of 99%+ is the baseline. If temperatures drop below 760°C, efficiency plummets, potentially producing CO or other incomplete combustion byproducts.

- RTO Exhaust Heat Recovery Efficiency: An efficiency above 95% means the temperature difference between inlet and outlet gas is minimal (often only 30-50°C), which is vital in high-energy-cost markets like the Netherlands.

Characteristics, Advantages, and Limitations

1. Ideal Scenarios: High Volume, Low-to-Mid Concentration

RTOs are most effective for airflows above 5,000 $m^3/h$ and concentrations between 1.5g and 8g/$m^3$. In Dutch softgel production, high ventilation rates used to maintain GMP cleanliness result in exhaust that is “large but dilute”—perfect for RTO technology.

2. Core Advantages

- Astounding Energy Efficiency: With TER at 97%, once VOC concentrations reach a certain “auto-thermal” point, the system requires virtually no natural gas.

- Low Operating Costs: Compared to traditional Thermal Oxidizers (TO), RTO long-term OPEX can be 60-80% lower.

- Low Carbon Footprint: Reduces fossil fuel usage, aligning with the Dutch Klimaatakkoord (Climate Agreement) requirements for industrial decarbonization.

3. Limitations & Solutions

- High Concentration Risks: If concentrations exceed 25% LEL (Lower Explosive Limit), the RTO may overheat. Solution: Implement a Hot Gas Bypass or fresh air dilution at the inlet.

- Particulate Clogging: Pill dust or oil mists can clog ceramic media. Solution: Install high-efficiency pre-filters (Baghouse or ESP).

Essential RTO Components & Ecosystem Recommendations

- Ceramic Media (Heat Sink)

- Recommendation: Honeycomb or saddle-shaped ceramics (Mullite).

- Feature: High surface area, low pressure drop, and chemical resistance.

- Poppet Valves

- Recommendation: Pneumatic zero-leakage poppet valves.

- Importance: These are the “gatekeepers” preventing untreated gas from leaking into the stack.

- Burners

- Brand Recommendation: Maxon or Eclipse modulating burners.

- Function: Provides precise heat control during the cold-start phase.

- Secondary Heat Recovery

- Suggestion: Add a heat exchanger downstream of the RTO to repurpose waste heat for HVAC or water preheating.

Mainstream RTO Brand Comparison Analysis

| Brand | Core Strength | Efficiency (TER/DRE) | Key Industries | Decision Criteria |

|---|---|---|---|---|

| Dürr (Ecopure) | German engineering; extremely stable; largest global install base. | 97% / 99.9% | Auto, Coating, High-end Pharma | Choose for absolute stability and high budget. |

| Ever-Power | Highly integrated; specialized in Softgel & Injectable niches. | 96% / 99.5% | Pharma, Softgel, Chemicals | Best for Cost-Performance & sector-specific customization. |

| Anguil | US brand; specializes in halogenated exhaust designs. | 95% / 99% | Chemical processing | Ideal for corrosive or complex gas streams. |

| Taikisha | Japanese brand; excellent reputation in Asian automotive markets. | 95% / 99% | Painting, Manufacturing | Focuses on large-scale coating line integration. |

Global and Local Market Application & Compliance

1. The Netherlands & EU Market

In the Netherlands, the ILT (Human Environment and Transport Inspectorate) requires pharmaceutical firms to submit detailed VOC management plans. RTO application directly aids in achieving BREEAM green building certification.

- Primary Industries: Chemical distribution, high-performance plastics, pharmaceuticals.

- Compliance Framework: EU IED (Industrial Emissions Directive).

2. Top Global Markets

- China: Strict enforcement of GB 37822-2019. RTO is virtually a prerequisite for chemical park entry.

- USA: Regulated under EPA Method 25A.

- Germany/Japan: Emphasis on energy recovery grades; smart AI control is increasingly standard.

3. SEO Multi-language Keywords

- English: Regenerative Thermal Oxidizer, VOC abatement, RTO efficiency.

- Nederlands: Thermische Naverbranding, VOS-reductie, Energie-efficiënte RTO.

- Deutsch: Regenerative Thermische Oxidation, Abluftreinigung.

Personal Implementation Experiences & Case Studies

Lessons from the Field: The Clogging Challenge

During a commissioning project in Noord-Brabant, we noticed the RTO pressure drop rising abnormally after just three months.

- The Challenge: Softgel exhaust contained trace oil mists that carbonized on the ceramic surfaces.

- The Fix: We retrofitted a three-stage pre-filtration system (G4+F7+H13) and introduced an automatic air-purge function.

- Takeaway: Do not underestimate the need for pre-treatment; it is the “heart” that determines the RTO’s lifespan.

Case Study: Dutch Pharmaceutical Major (50,000 $m^3/h$)

- Background: Transitioning from expensive, unstable activated carbon adsorption.

- Solution: Installation of a 3-bed RTO integrated with a secondary heat recovery system.

- Results: DRE reached 99.5%, with outlet concentrations < 5mg/$m^3$. The waste heat recovery saves roughly €120,000 in natural gas costs annually.

Future Trends & Unique Perspectives

- RTO + Carbon Capture (CCUS): In the future, RTOs won’t just destroy VOCs. Their clean, concentrated $CO_2$ streams can be captured and utilized in Dutch greenhouses, closing the carbon loop.

- Hydrogen-Ready Burners: To meet “Net Zero” targets, leading brands are developing hydrogen combustion systems to eliminate the carbon footprint of auxiliary natural gas.

- Adaptive AI Control: Using machine learning to predict production load swings and adjusting valve cycles in real-time can boost energy efficiency by an additional 2-3%.

Conclusion: An RTO is not a mere “incinerator”; it is a masterpiece of thermodynamic engineering. For Dutch pharmaceutical companies seeking long-term compliance and sustainability, selecting a high-spec, well-integrated RTO system is the definitive step toward a “Green Factory.”

Written by Environmental Engineering Experts. Contact us for insights into Dutch EIA subsidies or RTO selection.