HAP

Garis Panduan Komprehensif untuk Rawatan HAP di Belanda

Apakah RTO?

Pengoksidaan Terma Regeneratif (RTO) ialah teknologi kawalan pencemaran udara termaju yang direka untuk memusnahkan Sebatian Organik Meruap (VOC) dan Pencemar Udara Berbahaya (HAP) dalam gas ekzos perindustrian. Proses ini menggunakan suhu tinggi untuk mengoksidakan bahan berbahaya, memastikan pematuhan dengan peraturan alam sekitar seperti yang ditetapkan oleh EPA dan, dalam konteks Eropah, Arahan Pelepasan Perindustrian (IED) EU seperti yang dilaksanakan di Belanda.

Parameter Asas

Apakah itu HAP?

HAP ditakrifkan oleh badan kawal selia sebagai bahan pencemar yang menimbulkan risiko kesihatan yang ketara. Dalam konteks RTO, gas yang mengandungi HAP dikelaskan berdasarkan komposisi kimia, volatiliti dan ketoksikannya. Kategori biasa termasuk:

- HAP organik: Seperti benzena, toluena dan xilena.

- HAP bukan organik: Termasuk logam seperti arsenik dan merkuri.

- Sebatian Terhalogen: Seperti kloroform dan vinil klorida.

Sistem RTO amat berkesan untuk merawat HAP organik melalui penguraian terma, sejajar dengan piawaian pelepasan Belanda yang ketat.

Bagaimanakah RTO Mengurus HAP?

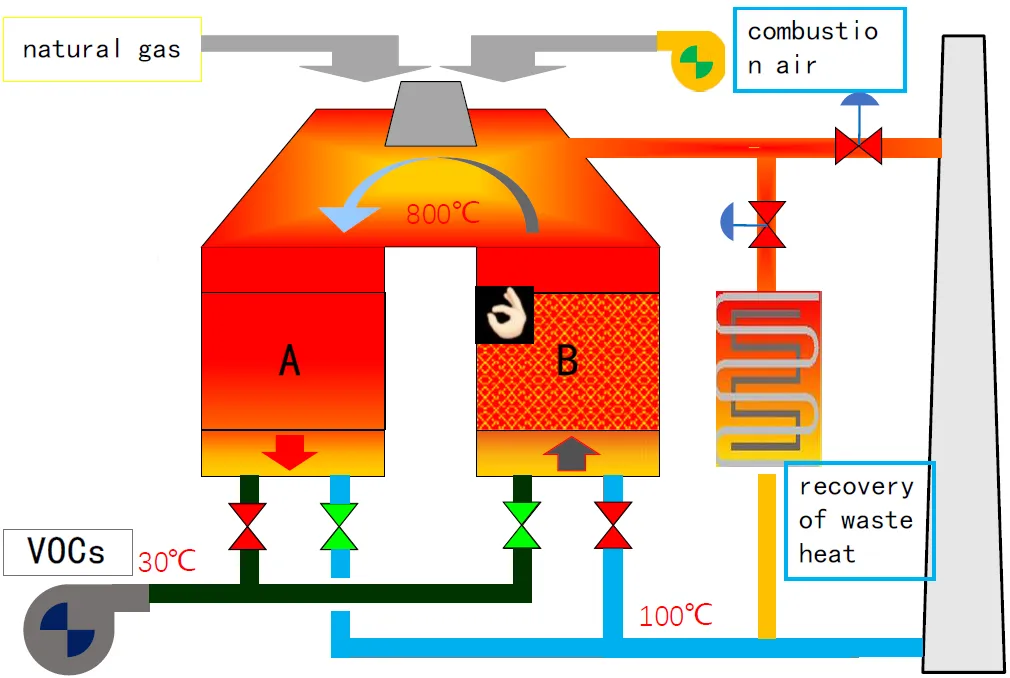

Sistem RTO biasanya terdiri daripada pelbagai lapisan media seramik yang digunakan untuk menangkap dan menjana semula tenaga haba bagi meningkatkan kecekapan tenaga. Proses khusus adalah seperti berikut:

- Pengenalan Gas Ekzos: Gas ekzos industri yang mengandungi HAP dimasukkan ke dalam unit RTO.

- Pengoksidaan Suhu Tinggi: Gas ekzos dipanaskan hingga kira-kira 800–1000°C (atau 1500°F), pada suhu tersebut, HAP mengalami penguraian oksidatif, menghasilkan CO₂ dan H₂O yang tidak berbahaya.

- Pemulihan Haba: Gas panas yang telah ditulenkan melalui lapisan media seramik, yang boleh menangkap sehingga 95% haba, yang digunakan untuk memanaskan gas ekzos yang masuk, sekali gus mengurangkan penggunaan tenaga.

- Pelepasan: Gas bersih dilepaskan melalui cerobong asap, mematuhi peraturan alam sekitar.

Proses ini memastikan kecekapan pemusnahan HAP biasanya melebihi 99%, menjadikannya sesuai untuk merawat gas ekzos bervolum tinggi dan berkepekatan rendah.

Kelebihan RTO dalam Tadbir Urus HAP

Kecekapan Tinggi

RTO direka khusus untuk memusnahkan sebatian organik meruap (VOC) dan HAP, dan sesuai untuk industri seperti kimia, percetakan dan farmaseutikal.

Reka Bentuk Penjimatan Tenaga

Mekanisme pemulihan haba regeneratif membolehkan sistem mencapai kecekapan terma sehingga 95%, sekali gus mengurangkan kos operasi dengan ketara.

Pematuhan Alam Sekitar

Ia dapat mengurangkan pelepasan HAP secara berkesan dan membantu perniagaan memenuhi piawaian kualiti udara yang ketat.

Kepakaran & Kelayakan

Industri Aplikasi

Industri Percetakan

Industri Salutan