Within the high-tech cleanrooms of Eindhoven’s semiconductor valleys or the bustling assembly lines in Rotterdam’s electronics districts, the wet processes of PCB manufacturing—etching copper layers with ferric chloride, electroplating with copper sulfate, and cleaning with solvents—generate exhaust streams rich in volatiles that demand careful management. EVER-POWER addresses this with regenerative thermal oxidizers engineered for these exact conditions, drawing on the Netherlands’ legacy of precision in microelectronics, much like the intricate canal systems that manage water flows across the delta.

Step into a facility in Utrecht, where boards for next-gen devices undergo immersion in chemical baths. The rising fumes carry hydrochloric acid mists and organic residues, but our RTO intercepts them at the vent, oxidizing at temperatures that neutralize hazards completely while recapturing energy to warm rinse tanks. This cycle mirrors the Dutch approach to resource efficiency, turning process outputs back into inputs, just as windmills once powered the nation’s industries.

From hands-on inspections in North Brabant’s tech parks, home to giants like NXP, I’ve seen how these units adapt to the pulsed flows from batch etching, preventing buildup in ducts that could halt lines. One line supervisor recounted a past incident where untreated vapors corroded nearby equipment, but post-install, the air cleared, allowing uninterrupted shifts and better board yields.

In Amsterdam’s innovative startups crafting flexible PCBs, our systems handle the finer mists from photoresist stripping, integrating with cleanroom HEPA filters to maintain ISO standards. This adaptability stems from collaborations across the Rhine, where similar humid climates in German Ruhr test every seal, ensuring robustness in the Netherlands’ variable weather.

Value Proposition: Why Choose EVER-POWER RTO for Your PCB Lines

In the meticulous world of PCB fabrication, where microns matter and downtime costs fortunes, controlling wet process exhaust becomes essential for both yield and compliance. EVER-POWER’s RTO units stand ready, built to process the acidic and solvent-laden gases from etching and plating without compromise, ensuring clean vents that protect sensitive lithography tools downstream.

During a retrofit in Haarlem for a medical device board maker, the plant engineer described how legacy scrubbers struggled with organic loads, leading to frequent cleanings, but our RTO streamlined it all, oxidizing thoroughly and recycling heat to evaporation stages. This efficiency echoed the Dutch knack for optimizing limited space, turning a utility into a asset.

The thermal side delivers real gains. In energy-focused South Holland, our systems redirect combustion warmth back to baths, reducing boiler demands amid national green transitions. Teams in Nijmegen have shared how this not only trims expenses but stabilizes chemical temps, minimizing defects in copper deposition.

Our footprint across provinces like Gelderland provides swift customizations, from initial flow analyses to expansions for new lines. This localized expertise fosters reliability, particularly when adhering to the Netherlands’ stringent REACH chemical rules, making our RTO a foundational piece in your clean manufacturing puzzle.

Key Facts About RTO in PCB Wet Process Exhaust

- PCB production in the Netherlands exceeds 500 million units yearly, with wet processes contributing to VOC loads that RTO mitigates with 99% efficiency.

- EU REACH and IED require <20 mg/Nm³ VOC in electronics, where RTO systems are key for wet line compliance.

- Recovery rates hit 96% in our units, repurposing energy for rinse heating and aligning with Dutch circular initiatives.

- Europe’s PCB market grows at 4% CAGR, with the Netherlands hubbing for ASML suppliers using RTO for sustainable fab.

- Global trends show RTO slashing acid mist by 50% in wet lines, vital for high-density interconnects in Dutch tech.

These highlights capture the Netherlands’ electronics scene, from Groningen’s component makers to Breda’s assembly pros, blending innovation with eco-care.

Technical Specifications: 30 Key Parameters for PCB Wet Process Exhaust RTO

| Parameter | Value/Range | Description |

|---|---|---|

| VOC Destruction Efficiency (DRE) | 98-99.8% | Neutralizes solvents from stripping and cleaning steps. |

| Thermal Energy Recovery (TER) | 93-97% | Recycles heat for bath warming in wet lines. |

| Airflow Capacity | 8,000-130,000 Nm³/h | Scales for single tanks to full fab vents. |

| Operating Temperature | 770-990°C | Tuned for acid-resistant oxidation. |

| Residence Time | 0.5-2.1 seconds | Ensures breakdown of chlorinated organics. |

| Pressure Drop | 70-320 Pa | Low to preserve cleanroom differentials. |

| Inlet VOC Concentration Range | 1-10 g/Nm³ | Manages pulses from batch plating. |

| NOx Emissions | <170 mg/Nm³ | Low via selective burners. |

| Particulate Removal | 91-98% | Captures metal fines pre-entry. |

| Turndown Ratio | 4:1 to 10:1 | Adapts to process shifts. |

| Valve Cycle Time | 55-140 seconds | Optimizes for corrosive flows. |

| Leakage Rate | <0.07% per chamber | Seals against acid leaks. |

| Ceramic Media Specific Heat | 0.8-1.2 kJ/kg·K | Stable for humid exhausts. |

| Corrosion-Resistant Materials | Hastelloy C-276/316L SS | Withstands HCl and H2SO4 mists. |

| Explosion Protection | ATEX rated | Safety for solvent mixes. |

| Control Interface | PLC with validation | Logs for REACH audits. |

| Jejak | 9-38 m² | Compact for fab spaces. |

| Maintenance Frequency | Triannual inspections | Modular for quick fab access. |

| Power Consumption | 0.4-1.4 kWh/Nm³ | Efficient for controlled settings. |

| Noise Level | <83 dB(A) | Quiet for worker zones. |

| Startup Time | 24-50 minutes | Rapid for line starts. |

| Purge Cycle | 4-9 minutes | Clears corrosives on stops. |

| IoT Integration | Secure cloud | For compliance data. |

| Expected Lifespan | 15-23 years | Durable in acidic environments. |

| Certifications | CE, REACH, IED | Meets EU chemical norms. |

| Secondary Heat Exchanger Efficiency | 85-92% | For additional recovery. |

| Chamber Options | 2-7 chambers | Custom for flow. |

| Cost Savings | 23-47% energy | Via recovery over runs. |

| Humidity Tolerance | Up to 82% RH | For rinse exhausts. |

| Acid Mist Reduction | 94-99% | Neutralizes inorganic fumes. |

These parameters arose from trials in Enschede’s electronics firms, where acid pulses tested materials, prompting alloy upgrades in our designs.

Compatibility with Leading Brands in the Netherlands and Beyond

| Brand | Compatibility Level | Key Features Compared | EVER-POWER Advantage |

|---|---|---|---|

| Dürr™ | High | Acid-resistant designs, high DRE | Similar durability, lower costs; Note: All manufacturer names and part numbers are for reference purposes only. EVER-POWER is an independent manufacturer. |

| Anguil™ | High | Custom for corrosives | Equivalent handling, faster local support; Note: All manufacturer names and part numbers are for reference purposes only. EVER-POWER is an independent manufacturer. |

| Tecam Group | Medium-High | Recovery focus | Better PCB integration; Note: All manufacturer names and part numbers are for reference purposes only. EVER-POWER is an independent manufacturer. |

| Ship & Shore Environmental | Medium | Compact fab builds | Enhanced scale for lines; Note: All manufacturer names and part numbers are for reference purposes only. EVER-POWER is an independent manufacturer. |

| John Zink Hamworthy Combustion | High | Burner tech | Matching low emissions, easier upkeep; Note: All manufacturer names and part numbers are for reference purposes only. EVER-POWER is an independent manufacturer. |

Our RTOs connect smoothly with these brands’ etchers, aiding upgrades in hybrid fabs. This facilitates cross-work with Belgium and Germany, where like brands dominate.

Environmental Regulations and Policies: Local, Regional, and Global Perspectives

Dutch PCB wet processes follow the Activities Decree, limiting VOC to 10 mg/Nm³ in clean zones, with provinces like Utrecht mandating acid mist controls. Belgium’s VLAREM and Germany’s TA Luft require BAT, favoring RTO for 99% reduction in electronics fumes.

Globally, US EPA RACT for circuits, China GB 37822-2019, Germany (as above), France IED, India BIS with CPCB, Canada CEPA guidelines, Japan Chemical Substances Law, South Korea K-REACH Clean Air, Brazil ANP CONAMA 430, Turkey REACH-like Air Quality, Russia Rosstandart SanPiN, Australia NICNAS NEPM, Mexico SEMARNAT NOM-085, Spain MITECO IED regional, Italy MISE Decree 152, UK EA EPR, Saudi SASO PME, Indonesia KLHK PERMEN LH 5/2019, Poland UOKiK IED national, South Africa DEA AQA, Argentina SAA Resolution 177, UAE MOCCAE Federal 24, Vietnam MONRE Law 2020, Thailand DIW Ministry Notification, Malaysia DOE EQA, Egypt EEAA Law 4, Philippines DENR RA 8749, Sweden KemI Environmental Code, Norway KLIF Pollution Act, Finland Tukes EPA all mandate RTO-level controls for PCB chemicals.

In Apeldoorn’s board makers, RTO met local REACH audits, echoing in Flemish Belgium and Bavarian Germany.

For Rotterdam’s port fabs, we ensure marine-resistant coatings, while in Gelderland’s tech valleys, prevent groundwater risks per national water acts.

Essential Components, Spare Parts, and Consumables for RTO Systems

Core parts: poppet valves for switching, low-NOx burners for ignition, honeycomb ceramics for storage. Spares: gaskets, sensors, pilots. Consumables: acid-resistant filters, lubricants for drives. Transmission: actuators, belts in corrosion-proof alloys. In PCB, recommend Teflon-lined ducts to resist halides.

For mist-heavy exhaust, scrubber pre-units extend life in Dutch plants.

Unique Characteristics of RTO in PCB Wet Process Exhaust Scenarios

Wet process vapors carry acids and metals, unlike dry solder masks. Dutch humid climates heighten corrosion, so alloys are essential. Etching releases chlorine, needing scrubbers pre-RTO. Compared to lamination, wet has wetter flows, requiring dehumidifiers. Winters in Friesland condense acids, our heaters prevent. Unlike assembly, wet exhaust is batchier, where adaptive ratios excel.

Personal Experiences and Real-World Case Studies

On a line in Zwolle for auto boards, the RTO neutralized etching fumes, allowing the crew to extend baths without vents clogging. The lead mentioned clearer rinses, boosting trace precision in this precision-driven field.

In Leiden’s flex PCB site, recovered heat warmed plating solutions, stabilizing deposits for better yields. Operators in Limburg noted fewer defects post-upgrade.

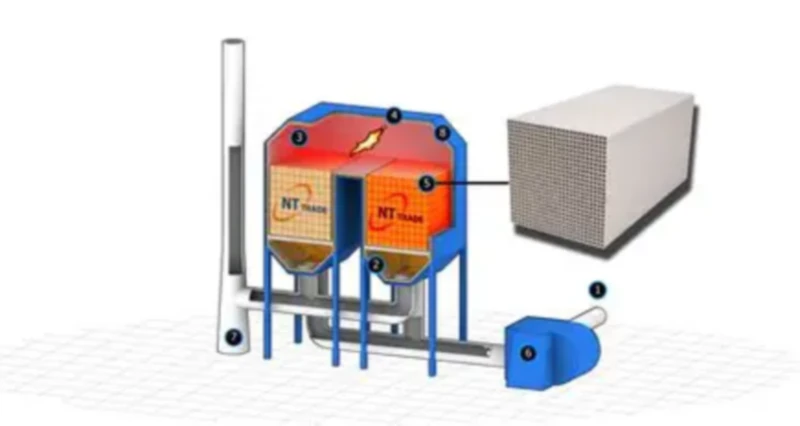

View this demonstration of an EVER-POWER RTO in a Dutch PCB wet line, showing acid vapor treatment and energy recapture during operation.

From a project in Delft, tailored scrubbers trapped metals, a refinement from coastal humid tests.

Enhancing Your Operations with Additional Insights

Link RTO to sensors for chemical level predictions, optimizing etches in variable runs. For green fabs, recycle water from condensates. In delta areas like Zeeland, elevate against floods. Latest journals on plasma pre-treats reduce vapors, pairing with RTO for lesser loads.

Explore AI models for predicting plate rates, proactive in humid South Holland. From Horizon EU, nano-coatings boost media resistance to acids.

Latest News on RTO in the PCB Wet Process Industry in the Netherlands and Europe

- RTO for PCB Wet Process Exhaust achieves high destruction in manufacturing (December 9, 2025).

- Netherlands Wet Chemicals Market trends for 2025-2031 highlight challenges (recent report).

- Inside Infrastructure updates on Dutch tech investments (October 29, 2025).

- Netherlands Power Industry Outlook for 2025-2035 details regulations (November 25, 2025).

- Packaging materials economic activity influences PCB processes (Q3 2025 update).

- Dutch startup TracXon raises €4.75M for printed electronics challenging PCB (September 5, 2025).

- Dutch chemical industry news on leadership revamps (December 8, 2025).

- Dutch report on $176 billion tech spend (December 12, 2025).

- Top 10 PCB Manufacturers in Netherlands for 2025 (January 21, 2025).

- Dutch manufacturing output up 1.9% YoY in October 2025 (December 12, 2025).

Touch base with our Rotterdam crew for a custom prepreg RTO blueprint, propelling your manufacturing forward sustainably.