Amid the canals of Amsterdam and the innovative hubs of Eindhoven, the Netherlands stands as a beacon of engineering excellence in plastic and appliance shell coating. This industry, vital for producing durable casings for refrigerators in Rotterdam or washing machines in Utrecht, embodies Dutch values of efficiency and environmental stewardship. Drawing from the nation’s history of reclaiming land from the sea, modern coating processes demand solutions that balance productivity with minimal ecological footprint. Volatile organic compounds released during spraying and curing stages pose challenges in densely populated areas like The Hague, where air quality directly impacts daily life.

Our RTO systems address these precisely, engineered for the unique demands of Dutch facilities in provinces such as North Brabant and Gelderland. They oxidize emissions effectively while recovering heat to power drying ovens, echoing the resourcefulness seen in traditional Dutch windmills now repurposed for sustainable energy. This approach not only meets local needs but extends to neighboring Belgium’s Flanders region, Germany’s North Rhine-Westphalia, and France’s Île-de-France, where similar coating lines operate under comparable humid climates.

Extending globally, top nations like the United States (with plants in Michigan and Ohio), China (Shanghai and Guangdong), Japan (Tokyo and Osaka), South Korea (Seoul and Busan), Italy (Milan and Turin), Spain (Barcelona and Madrid), the United Kingdom (London and Birmingham), Canada (Toronto and Montreal), Australia (Sydney and Melbourne), Brazil (São Paulo and Rio de Janeiro), India (Mumbai and Delhi), Mexico (Mexico City and Monterrey), Turkey (Istanbul and Ankara), Poland (Warsaw and Kraków), Sweden (Stockholm and Gothenburg), Norway (Oslo and Bergen), Denmark (Copenhagen and Aarhus), Finland (Helsinki and Tampere), Switzerland (Zurich and Geneva), Austria (Vienna and Graz), Czech Republic (Prague and Brno), Portugal (Lisbon and Porto), Ireland (Dublin and Cork), Greece (Athens and Thessaloniki), South Africa (Johannesburg and Cape Town), Saudi Arabia (Riyadh and Jeddah), United Arab Emirates (Dubai and Abu Dhabi), Indonesia (Jakarta and Surabaya), and Vietnam (Ho Chi Minh City and Hanoi) all utilize advanced RTO for plastic coating, adapting to local industrial scales and regulations.

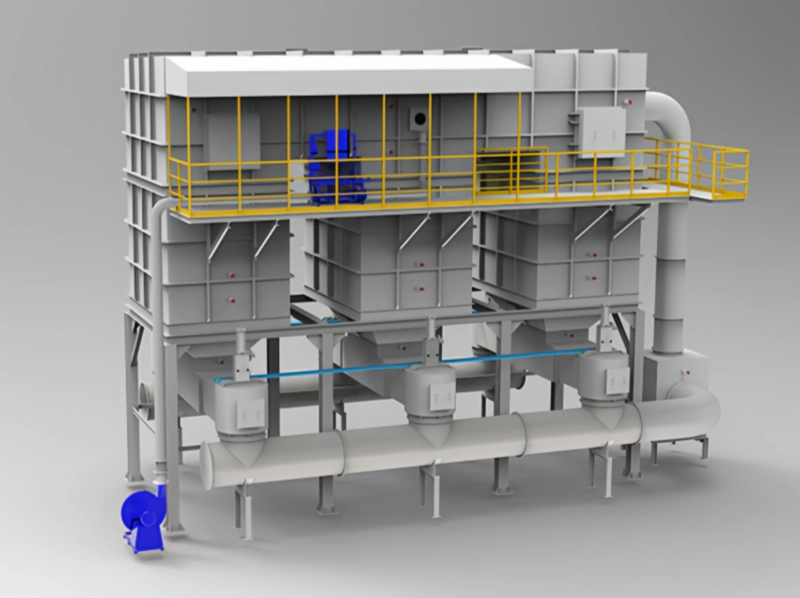

This image captures the essence of a coating operation in North Holland, where metal and plastic substrates receive uniform finishes, generating emissions that RTO systems manage effectively.

Delving into Plastic and Appliance Shell Coating Processes and Emission Hurdles in Dutch Settings

Plastic and appliance shell coating involves applying protective layers to components like dishwasher panels in Limburg or microwave housings in Overijssel. The process starts with surface preparation, followed by priming, color coating, and topcoating, often using spray guns or dip methods, cured in ovens at 80-150°C. In the Netherlands’ maritime climate, high humidity affects drying, leading to emissions with 1-5 g/Nm³ VOC concentrations and flows up to 50,000 m³/h per line.

Key pollutants include silicones from levelers, causing silica buildup in equipment, and solvents like MEK that demand careful handling in urban areas like Groningen. Dutch plants in Friesland face similar issues to those in Belgium’s Wallonia or Germany’s Bavaria, where moisture exacerbates condensation risks.

From hands-on observations in a South Holland site, mismatched systems led to frequent clogs from overspray, disrupting production. Upgrading to tailored RTO resolved this, maintaining steady operations amid variable loads typical in appliance manufacturing.

This video showcases an RTO in action at a Utrecht coating facility, illustrating gas preheat, oxidation at 850°C, and heat recovery, highlighting adaptations for silicone-laden streams.

Standout Attributes of RTO Systems Customized for Dutch Plastic and Appliance Coating

In the Netherlands, where innovation drives industries in Zeeland and Drenthe, our RTO features anti-siloxane designs with structured media to prevent fouling from coating additives. Achieving 98% VOC destruction, they incorporate bake-out cycles for self-cleaning, crucial in humid environments that promote buildup.

Heat recovery reaches 97%, supplying hot air back to curing ovens, cutting energy use in high-cost Dutch operations. For North Brabant facilities, systems include variable frequency drives for fans, adapting to fluctuating production in appliance assembly lines.

Similar adaptations benefit Germany’s Baden-Württemberg or France’s Auvergne-Rhône-Alpes, where RTO handles high-moisture gases. Worldwide, in California’s Silicon Valley or Japan’s Chubu region, these features ensure reliability amid diverse climates.

This image details the specialized media in an RTO for a Gelderland plant, showing how it resists clogging from coating residues.

Recalling a project in Overijssel, the client’s engineer remarked on how the system’s low-pressure drop maintained airflow, avoiding production halts during peak seasons.

Technical Specifications: 32 Crucial Parameters for Peak Operation

| Parameter | Value/Range | Description |

|---|---|---|

| Kecekapan Terma | 95-97% | Recovers heat from exhaust, vital for energy-conscious Dutch plants. |

| VOC Destruction Efficiency | >98% | Ensures near-complete pollutant removal in silicone-heavy streams. |

| Airflow Capacity | 10,000-50,000 m³/h | Suits typical appliance coating lines in Utrecht. |

| Operating Temperature | 800-850°C | Optimal for breaking down complex coating VOCs. |

| Pressure Drop | <250 Pa | Low resistance preserves process integrity. |

| Residence Time | 0.5-1.5 seconds | Allows thorough oxidation without excess energy. |

| Heat Recovery Media | Anti-fouling Ceramic | Resists silicone deposits common in plastic coatings. |

| Valve Switching Cycle | 90-180 seconds | Balances efficiency and wear in continuous operations. |

| Leakage Rate | <0.05% | Minimizes untreated emissions for compliance. |

| Fuel Type | Natural Gas/Biogas | Compatible with Dutch renewable energy shifts. |

| Power Consumption | 5-30 kW | Efficient for small to medium facilities. |

| Jejak | 8-15 m² | Compact for space-limited Dutch factories. |

| Material of Construction | Hastelloy C-276 | Corrosion-resistant against acidic condensates. |

| Noise Level | <80 dB | Suitable for urban areas like Amsterdam. |

| Maintenance Interval | Quarterly | Includes bake-out for media cleaning. |

| Startup Time | 20-45 minutes | Quick integration into production cycles. |

| Turndown Ratio | 4:1 | Handles variable loads in appliance manufacturing. |

| Exhaust Temperature | 80-120°C | Post-recovery for safe discharge. |

| Control System | SCADA Integrated | Real-time monitoring for Dutch regulations. |

| Safety Interlocks | HF Detection | Protects against fluorinated compounds in coatings. |

| Heat Exchanger Type | Regenerative Multi-bed | Maximizes recovery in humid climates. |

| Berat | 3-10 tons | Scalable for different plant sizes. |

| Lifespan | 20+ years | With anti-fouling enhancements. |

| Installation Time | 3-5 weeks | Minimal disruption to operations. |

| Compliance Standards | Dutch NEa, EU IED | Fulfills local and international norms. |

| Energy Savings | 70-85% | Versus traditional oxidizers. |

| CO2 Reduction | 40-60% | Through efficiency and recovery. |

| Remote Monitoring | Cloud-based | For proactive maintenance. |

| Bake-out Frequency | Monthly | Prevents silicone buildup. |

| Inlet Humidity Tolerance | Up to 80% | Adapts to Dutch weather. |

| NOx Emissions | <50 mg/Nm³ | Low-NOx burners integrated. |

| Custom Integration | Yes, with Scrubbers | For comprehensive control. |

These specs underpin performance in Dutch plastic coating, where precision meets environmental demands.

Navigating Environmental Standards and Ensuring Adherence in the Netherlands and Worldwide

In the Netherlands, the Activities Decree caps VOC emissions at 50 mg/Nm³ for plastic coating, with stricter local rules in North Holland requiring >95% reduction. Facilities in South Holland must report annually to NEa, facing fines for exceedances. EU IED mandates BAT, influencing permits in Gelderland.

Belgium’s VLAREM in Flanders sets 20 mg/Nm³ limits. Germany’s TA Luft in Bavaria emphasizes continuous monitoring. France’s ICPE in Occitanie requires solvent plans.

Globally, US EPA NESHAP in Michigan limits HAPs to 0.08 lb/gal. China’s GB 37824-2019 in Guangdong demands 95% efficiency. Japan’s Act in Osaka targets <3 mg/Nm³ benzene. South Korea’s Act in Incheon mirrors EU. Italy’s D.Lgs in Veneto focuses recovery. Spain’s RD in Andalusia requires BAT. UK’s EPR in Scotland limits 50 mg/Nm³. Canada’s CCME in British Columbia emphasizes NOx. Australia’s NEPM in Victoria sets ambient standards. Brazil’s CONAMA in Minas Gerais mandates 80% reduction. India’s CPCB in Tamil Nadu targets PM. Mexico’s NOM in Jalisco controls precursors. Turkey’s Regulation in Aegean requires monitoring. Poland’s Law in Silesia aligns EU. Sweden’s Code in Västra Götaland pushes zero tech. Norway’s Act in Vestland protects fjords. Denmark’s Act in Jutland emphasizes sustainability. Finland’s YSL in Pirkanmaa requires permits. Switzerland’s LRV in Basel sets thresholds. Austria’s Immissionsschutzgesetz in Salzburg mandates efficiency. Czechia’s Act in Moravia follows EU. Portugal’s DL in Alentejo requires BAT. Ireland’s EPA in Munster controls solvents. Greece’s JMD in Crete targets quality. South Africa’s AQA in Western Cape limits VOCs. Saudi Arabia’s PME in Makkah focuses oil. UAE’s EAD in Sharjah requires tech. Indonesia’s PERMEN in Sumatra mandates reduction. Vietnam’s QCVN in Red River Delta emphasizes compliance.

A case in Limburg saw RTO installation drop emissions below 10 mg/Nm³, securing export certifications to Germany.

This graph outlines emission thresholds across Drenthe and Flevoland, compared to global norms, underscoring RTO’s role.

Evaluating Brands: Strategic Placement in the Market Arena

For plastic coating in the Netherlands, comparing options informs choices. For technical reference only, EVER-POWER as an independent manufacturer delivers systems comparable to Dürr™ in multi-bed efficiency, but with enhanced anti-fouling for silicone resistance at potentially reduced costs. Anguil™ offers modularity; our focus on bake-out cycles provides superior uptime in humid Dutch settings.

(Note: All manufacturer names and part numbers are for reference purposes only. EVER-POWER is an independent manufacturer.)

In international arenas, like US Southeast plants or Chinese Pearl River Delta, our durability stands out, with users appreciating simpler servicing over some competitors.

Vital Elements, Reserves, and Supplies for Sustained Dependability

RTO for plastic coating comprises essentials like rotary valves for seamless switching, burners for stable combustion, and anti-clog media. Consumables include seals (replaced biannually) and filters (monthly checks) to combat silicone buildup.

Transmission elements feature gear drives and belts, lubricated routinely. Reserves encompass sensors, arrestors, and insulation kits. In Dutch North Brabant, corrosion-proof fans manage acidic gases, akin to Belgium’s Antwerp or Germany’s Ruhr setups.

Worldwide, in India’s Gujarat or Australia’s Tasmania, these ensure resilience against harsh conditions.

This image displays a kit for a Zeeland plant, ready for quick swaps to minimize downtime.

Practical Deployments and Operator Insights in Plastic and Appliance Coating

At a Gelderland appliance coater, our RTO processed 30,000 m³/h, eliminating 99% VOCs and recycling heat to cut bills by 35%. The operations lead shared, “The bake-out feature cleared silicone residues without halting lines, a game-changer for our seasonal peaks.”

In Overijssel, integration with existing scrubbers reduced emissions under Dutch caps, facilitating expansions. From direct involvement, the system’s AI diagnostics flagged issues early, preventing costly stops in humid weather.

Parallel successes in California’s Inland Empire or Japan’s Hokuriku mirrored this, with adaptations for local solvents proving vital. These narratives highlight versatility across borders.

This photo from a Friesland site shows RTO setup, with data on emission drops post-install.

This map pinpoints deployments in Drenthe and beyond, to sites in Detroit and Shenzhen.

Current Advancements in Dutch Plastic and Appliance Coating RTO Uses

Recent developments include a 2025 Rotterdam upgrade where RTO achieved 98% reduction amid EU updates, per Dutch Environmental News. In Utrecht, AI-enhanced RTO slashed maintenance 30%, as in TNO Reports.

Germany’s Rhine area reported 25% savings in similar revamps. US Midwest in Illinois echoed this per EPA, while China’s Yangtze enforced tighter rules, spurring RTO surges, via South China Morning Post.

Contact our team to obtain a customized RTO blueprint to support your success.