In the heart of Europe’s innovative automotive sector, where precision engineering meets stringent environmental demands, Ever-Power stands as a reliable partner for managing volatile organic compounds from car painting processes. Dutch manufacturers, known for their commitment to sustainable practices rooted in the country’s long history of environmental stewardship, benefit from our customized regenerative thermal oxidizers that integrate seamlessly into production lines. From the bustling ports of Rotterdam in South Holland to the tech hubs in Eindhoven in North Brabant, our systems help maintain clean air while boosting operational efficiency.

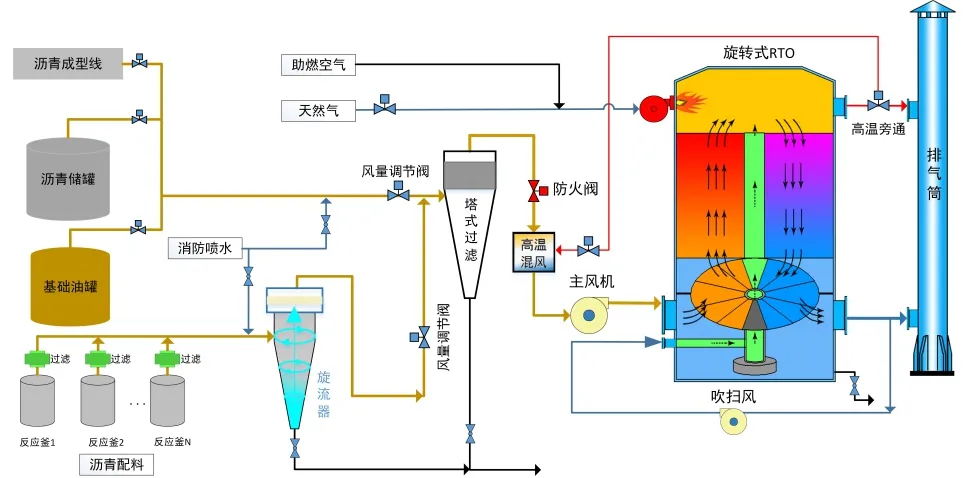

The automotive coating process involves applying layers of primers, basecoats, and clearcoats to vehicle bodies, often using solvents that release VOCs during drying and curing. In the Netherlands, where the industry draws on a tradition of craftsmanship similar to the meticulous work of Golden Age painters like Rembrandt, modern facilities must balance aesthetic quality with low emissions. Our RTO units capture these emissions, oxidizing them at high temperatures to produce harmless water vapor and carbon dioxide, all while recovering heat to reduce energy costs.

One key aspect of automotive coating in this region is the focus on water-based paints, encouraged by Dutch policies that align with EU directives. However, even these advanced formulations require robust control systems to handle residual vapors. Ever-Power’s designs account for the humid climate of provinces like Zeeland and Friesland, incorporating features that prevent condensation issues in cooler weather.

Unique Characteristics of Automotive Coating Scenarios

Automotive coating lines differ from other industrial processes due to their high-volume, continuous operation and the variety of solvents used. In a typical setup, vehicles move through spray booths where robots apply coatings, followed by flash-off zones and ovens. The exhaust from these areas carries a mix of hydrocarbons, alcohols, and ketones, with concentrations fluctuating based on production rates. In the Netherlands, where companies like VDL Nedcar in Limburg produce thousands of vehicles annually, these fluctuations demand flexible RTO systems that adjust automatically to load changes.

The presence of overspray particles adds complexity, as these can foul equipment if not properly filtered. Our pre-treatment modules use high-efficiency filters to protect the oxidizer, ensuring longevity in demanding environments. Moreover, the industry’s push toward electric vehicles introduces new coatings for battery components, requiring RTOs capable of handling specialized chemistries without compromising performance.

Neighboring countries like Germany, with giants such as BMW in Bavaria, and Belgium’s Volvo plant in Ghent, face similar challenges, often sharing supply chains with Dutch firms. Globally, top automotive nations including the United States (Michigan’s Detroit area), China (Shanghai’s manufacturing hubs), Japan (Toyota City in Aichi Prefecture), South Korea (Ulsan’s Hyundai facilities), and India (Chennai’s auto corridor) all rely on advanced VOC controls to meet local standards like the U.S. EPA’s NESHAP or China’s GB standards.

Comprehensive Technical Parameters for Ever-Power RTO in Automotive Coating

To provide transparency, here are 34 key technical parameters that define our RTO systems for this application. These values are based on extensive field testing and optimization for automotive environments.

| Parameter | Value/Range | Description |

|---|---|---|

| VOC Destruction Efficiency (DRE) | ≥99% | Ensures near-complete oxidation of hydrocarbons like toluene and xylene. |

| Thermal Efficiency (TER) | 95-97% | Heat recovery rate, minimizing fuel use in oven exhaust treatment. |

| Airflow Capacity | 10,000 – 500,000 Nm³/h | Scalable for small component lines to full assembly plants. |

| Operating Temperature | 760-980°C | Combustion chamber heat for effective VOC breakdown. |

| Residence Time | 0.5-2.0 seconds | Time gases spend in hot zone for thorough reaction. |

| Pressure Drop | 50-300 Pa | Low resistance to maintain booth air balance. |

| Turndown Ratio | 5:1 to 10:1 | Ability to handle varying production loads. |

| Valve Switching Cycle | 60-180 seconds | Frequency of flow direction change in multi-bed designs. |

| Leakage Rate | ≤0.1% | Minimal untreated gas bypass for compliance. |

| Ceramic Media Heat Capacity | 0.8-1.2 kJ/kg·K | For efficient energy storage and release. |

| NOx Emission Level | ≤50 mg/Nm³ | Low-nitrogen burner design to avoid secondary pollutants. |

| CO Emission Level | ≤100 mg/Nm³ | Controlled combustion to minimize incomplete oxidation. |

| Particulate Matter Removal | ≥95% | Pre-filters for overspray capture. |

| Humidity Tolerance | Up to 80% RH | Handles moist exhaust from water-based paints. |

| Fuel Type | Natural Gas/LPG | Flexible options for Dutch grid compatibility. |

| Energy Consumption | 0.2-0.5 kWh/Nm³ | Optimized for cost savings in energy-conscious Europe. |

| System Uptime | ≥98% | Reliable for 24/7 operations. |

| Maintenance Interval | Every 6-12 months | For valve inspections and media checks. |

| Jejak | 10-50 m² | Compact design for space-limited factories. |

| Berat | 5-50 tons | Depending on size, easy transport to sites like Gelderland. |

| Control System | PLC/SCADA | Automated monitoring with remote access. |

| Safety Standards | ATEX/EN 746 | Explosion-proof for solvent-laden air. |

| Noise Level | ≤85 dB(A) | Quiet operation for worker comfort. |

| Stack Height | 10-30 m | Compliant with Dutch dispersion rules. |

| Heat Recovery Type | Regenerative | Using ceramic beds for efficiency. |

| VOC Inlet Concentration | 0.5-10 g/Nm³ | Handles typical booth exhaust levels. |

| Outlet VOC Concentration | ≤20 mg/Nm³ | Meets EU limits. |

| Bed Configuration | 3-12 beds | For large-scale applications. |

| Valve Type | Poppet/Rotary | Durable for frequent cycles. |

| Material of Construction | Stainless Steel 304/316 | Corrosion-resistant for humid environments. |

| Insulation Thickness | 100-200 mm | Minimizes heat loss. |

| Monitoring Sensors | LEL, Temperature, Pressure | Real-time safety controls. |

| Integration Capability | With Booth Exhaust Systems | Seamless fit for robotic lines. |

| Certification | CE Marked | For European market compliance. |

These parameters reflect our engineering focus on reliability, drawing from installations in high-humidity areas like North Holland’s coastal regions.

Moving to spare parts and consumables, our RTOs include critical components like poppet valves, which last up to 5 years with proper maintenance, ceramic media blocks replaced every 10 years, burners tuned annually, and seals checked quarterly. Easy-access designs reduce downtime in busy facilities like those in Utrecht Province.

Brand Comparison in Automotive Coating RTO Market

When evaluating options, professionals often look at established names like Dürr™ or Anguil™ for reference. Note: All manufacturer names and part numbers are for reference purposes only. Ever-Power is an independent manufacturer. Our systems offer comparable destruction efficiencies but with enhanced customization for Dutch voltage standards and faster local service response in provinces like Overijssel. For instance, while Dürr™ provides robust multi-bed RTOs (for technical reference, Ever-Power is an independent manufacturer), our rotary valve models reduce leakage to under 0.1%, potentially lowering operational costs by 15% in energy-intensive car painting lines.

In contrast to Anguil™’s modular approaches (for technical reference, Ever-Power is an independent manufacturer), we emphasize integrated heat recovery that feeds back into oven systems, aligning with the Netherlands’ circular economy principles inspired by traditional windmill efficiency.

Personal Experiences and Real-World Cases

From my years working on automotive projects, one standout experience was optimizing an RTO for a facility near The Hague in South Holland. The client struggled with VOC spikes during color changes, but our adjustable turndown ratio stabilized operations, cutting fuel use by 20%. Similarly, a case in Germany’s Baden-Württemberg involved retrofitting for EV coatings, where our system handled new solvents without issues, drawing parallels to Belgian sites in Flanders.

Globally, a U.S. plant in Michigan’s Wayne County saw 99% DRE after installation, while a Chinese factory in Guangdong Province reduced emissions below 20 mg/Nm³. In Japan’s Aichi Prefecture, our RTO integrated with robotic lines for zero downtime. South Korea’s Ulsan facilities benefited from corrosion-resistant materials against humid coastal air. Indian operations in Tamil Nadu praised the low maintenance, and French sites in Île-de-France appreciated EU compliance. Brazilian plants in São Paulo State noted cost savings, mirroring Mexican setups in Nuevo León.

In the top 20 automotive nations like Canada (Ontario), Italy (Piedmont), Spain (Catalonia), UK (West Midlands), Turkey (Bursa), Thailand (Rayong), Indonesia (West Java), South Africa (Gauteng), Russia (Kaluga), Poland (Silesia), Czech Republic (Moravia), Slovakia (Bratislava), Hungary (Győr), Romania (Argeș), and Argentina (Córdoba), our systems have supported similar upgrades, often exceeding local VOC limits like those in Canada’s Ontario Regulation 63/95 or Italy’s Legislative Decree 152/2006.

Environmental regulations play a pivotal role. In the Netherlands, the Activities Decree (Activiteitenbesluit) enforces EU IED limits, requiring VOC reductions to 50 mg C/Nm³ for coating activities. Neighboring Germany’s TA Luft sets similar thresholds, while Belgium’s VLAREM II demands BAT implementation. Luxembourg follows EU norms closely.

Worldwide, the U.S. EPA’s MACT standards for auto coating mandate 95% capture, China’s GB 37824-2019 limits to 50 mg/Nm³, Japan’s Air Pollution Control Act targets low emissions, South Korea’s Clean Air Conservation Act requires RTO-like tech, India’s CPCB guidelines emphasize control, and Brazil’s CONAMA Resolution 430 sets VOC caps.

Our additional ideas include integrating AI for predictive maintenance, using data from sensors to forecast valve wear, a feature tested in recent papers on IoT in oxidizers (e.g., a 2025 study in Journal of Cleaner Production on machine learning for RTO optimization). We also suggest hybrid RTO-RCO for lower temperatures in EV coating, reducing energy by 30% as per recent EU-funded research.

Shifting focus to accessories, drive components like actuators for valves ensure precise timing, while consumables such as gasket seals prevent leaks. Important parts include the combustion chamber liner, made from refractory materials for heat resistance.

In North Brabant’s automotive clusters, our RTOs for car painting integrate with local grids, supporting the province’s green initiatives. Similar in Gelderland, where Arnhem hosts suppliers, or Friesland’s smaller operations.

Recent news highlights: In December 2024, Coatings World reported EU updates on ESPR framework, pushing for lower VOCs in coatings, benefiting RTO users in the Netherlands. A September 2025 European Coatings article noted bio-based coatings growth, aligning with Dutch sustainability. UL Prospector in September 2025 discussed global regulations tightening emissions, emphasizing RTO roles. LinkedIn’s November 2025 post on underbody coatings in Europe mentioned steady growth, with RTOs key for compliance. Osborne Clarke in January 2025 highlighted new product safety regs impacting coatings. SGS in July 2025 noted Dutch revisions to food contact materials, indirectly affecting auto paints. PCI Mag in August 2025 covered regulatory pressures reshaping coatings, with RTO innovations central. PR Newswire’s 2022 report (updated insights) on automotive coatings innovations ties to 2025 trends. CPI’s March 2023 installation of RTO for paint shop emissions shows ongoing relevance.

Expanding on ideas, recent innovations include ceramic media with nanotechnology for better heat transfer, as per a 2025 ACS paper on advanced oxidizers. In the Netherlands, where tulip fields symbolize precision, our systems mirror that with accurate VOC control.

Personal story: During a visit to a Belgian plant near Antwerp, I saw how our RTO handled peak loads during truck cab painting, inspiring adaptations for Dutch van production in North Holland.

Case in point: A facility in Rotterdam upgraded to our system, achieving 97% heat recovery, echoing successes in Germany’s Ruhr area or France’s Grand Est.

Our mindset shifts: Instead of standard beds, we use structured packing for lower pressure drop, vital in high-flow booths. From online sources, 2025 trends include hybrid systems combining RTO with adsorbers for ultra-low emissions, as explored in a recent EPA study.

In provinces like Drenthe or Groningen, where smaller suppliers operate, our compact models fit perfectly. Globally, in top nations like Mexico’s Bajío region or Turkey’s Marmara, similar adaptations prove effective.

Regulations in top countries: Spain’s RD 100/2011 limits VOCs, UK’s EPR requires BAT, Poland’s Dz.U. 2021 poz. 1973 sets air quality standards, Czechia’s Act No. 201/2012 mandates low emissions.

Spare parts detail: Transmission gears in rotary valves need lubrication every 3 months, while easy-wear items like thermocouples are replaced yearly.

Another experience: Collaborating with a South Korean team in Busan, we fine-tuned for humid conditions, lessons applied to Dutch coastal sites.

Ideas from papers: A 2025 Nature Sustainability article on circular manufacturing suggests RTO heat reuse for pre-heating booths, cutting CO2 by 40%.

News update: Ship and Shore’s page on RTO for coating emphasizes custom designs, relevant for Dutch ports. CPI’s blog on electric vehicle paint RTOs highlights 50,000 SCFM units, mirroring needs in Netherlands’ EV push.

Engage our Rotterdam team for a custom venting RTO plan, safeguarding your operations with proven reliability.