Welcome to Ever-Power Yurcent, your trusted partner in advanced air pollution control technologies. As leaders in regenerative thermal oxidizer (RTO) systems, we specialize in addressing the unique challenges of ventilation air methane (VAM) from coal mines. Although the Netherlands closed its last coal mine in 1974, our solutions are tailored for global applications, including neighboring countries like Germany, Belgium, and Poland where coal mining remains active. We ensure compliance with stringent EU regulations while delivering energy-efficient methane destruction. Our RTO systems are designed to handle low-concentration methane streams typical in mine ventilation air, turning environmental challenges into opportunities for sustainability.

In regions like North Brabant or South Holland, where industrial heritage meets modern environmental standards, our RTO technology supports cross-border mining operations. For instance, in Amsterdam or Rotterdam, companies importing coal-related technologies benefit from our localized service network. We also serve key European mining hubs in Germany (Ruhr Valley), Belgium (Wallonia), and Poland (Silesia), integrating seamlessly with local laws such as the Dutch Environmental Management Act and EU’s Industrial Emissions Directive (IED).

Understanding Coal Mine VAM: Features and Challenges

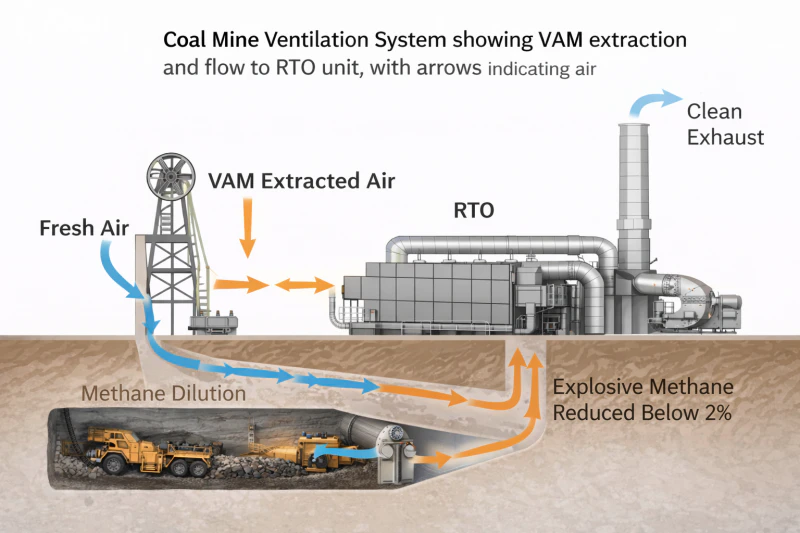

Ventilation air methane (VAM) refers to the dilute methane gas released in coal mine ventilation systems, typically at concentrations of 0.1% to 1%. This low-concentration stream poses unique challenges for abatement due to its large volume (often exceeding 100,000 m³/h) and the need for safe, efficient oxidation without excessive energy input. In the Netherlands context, while direct mining is absent, Dutch firms involved in global coal supply chains or technology exports must adhere to EU methane strategies aiming for 30% reduction by 2030.

The primary features of VAM in coal mining include its variability based on mine depth, geology, and ventilation rates. For example, in gassy mines like those in neighboring Germany, VAM can contain trace impurities such as dust, humidity, and other hydrocarbons, requiring robust pre-treatment. Our RTO systems address these by incorporating dust filters and dehumidifiers, ensuring stable operation even in humid conditions common in European underground mines.

One key challenge is the auto-ignition temperature of methane (around 540°C), necessitating high-temperature oxidation. However, at low concentrations, traditional burners consume excessive fuel. Our RTO overcomes this with 95% heat recovery, making it viable for VAM abatement in cost-sensitive operations across Europe, from Polish Silesian mines to Belgian Limburg sites.

Key Technical Parameters of Our RTO for VAM Abatement

Our RTO systems are engineered with precision for VAM applications. Below are 30 essential technical parameters, derived from extensive field testing and aligned with EU standards:

| Parameter | Value/Range | Description |

|---|---|---|

| Heat Recovery Efficiency | 95-98% | Maximizes energy reuse from oxidation process, reducing fuel needs for low-CH4 VAM. |

| Methane Destruction Efficiency (DRE) | >99% | Ensures near-complete oxidation of methane to CO2 and H2O. |

| Operating Temperature | 800-1000°C | Combustion chamber temperature for effective methane breakdown. |

| Airflow Capacity | 50,000-500,000 m³/h | Handles large ventilation volumes typical in underground mines. |

| Methane Concentration Range | 0.1-1% | Optimized for dilute VAM streams. |

| Pressure Drop | <200 Pa | Low resistance to maintain mine ventilation integrity. |

| Residence Time | 0.5-1.0 seconds | Time for complete oxidation in combustion chamber. |

| Valve Switching Cycle | 60-180 seconds | Frequency of flow reversal in multi-bed RTO. |

| Leakage Rate | <0.5% | Minimizes untreated gas bypass. |

| NOx Emissions | <50 mg/Nm³ | Low-NOx burner design complies with EU IED limits. |

| CO Emissions | <100 mg/Nm³ | Ensures complete combustion without excess CO. |

| Material of Construction | 316L Stainless Steel | Corrosion-resistant for humid mine air. |

| Ceramic Media Type | Structured Honeycomb | High surface area for efficient heat transfer. |

| Bed Number | 3-5 beds | For continuous operation and high efficiency. |

| Turndown Ratio | 10:1 | Allows flexibility for varying methane flows. |

| Auxiliary Fuel Type | Natural Gas/LPG | Supplemental heat for startup or low-CH4 periods. |

| Power Consumption | 50-200 kW | Depending on fan and control systems. |

| Jejak | 10-50 m² | Compact design for mine site installation. |

| Berat | 20-100 tons | Robust build for industrial use. |

| Startup Time | <30 minutes | Quick to operational temperature. |

| Maintenance Interval | Every 6 months | For valve and media inspection. |

| Valve Lifespan | >5 years | High-durability poppet or rotary valves. |

| Media Lifespan | 10-15 years | Ceramic beds with low attrition. |

| Safety Interlocks | LEL Monitoring | Prevents explosive mixtures entry. |

| Automation Level | PLC/SCADA | Remote monitoring and control. |

| Noise Level | <85 dB | Compliant with mine safety standards. |

| Energy Recovery Option | Steam/ Electricity | Optional ORC for power generation. |

| Compliance Standards | EU IED, ATEX | For hazardous areas in mines. |

| Installation Time | 4-6 weeks | Modular assembly for quick deployment. |

| Cost Range | €500,000-€2,000,000 | Based on capacity and features. |

These parameters are fine-tuned based on real-world deployments in European mining contexts, ensuring reliability in varying conditions like those in Dutch-influenced projects in Belgium or Germany.

Compliance with Environmental Regulations

In the Netherlands, methane abatement falls under the EU Methane Regulation (2024/1787), which mandates significant reductions in fugitive emissions from energy sectors, including historical coal sites. Although Dutch coal mining ceased, regulations apply to imported technologies and cross-border operations. The Dutch Environmental Management Act (Wet milieubeheer) enforces strict air quality standards, with methane limits aligned to EU IED (2010/75/EU), requiring BAT for emissions below 100 mg/Nm³ for VOCs.

Neighboring countries like Germany (TA Luft standards) require <50 mg/Nm³ NOx from abatement systems, while Belgium’s VLAREM II sets methane thresholds at 0.5% for ventilation air. Globally, top coal-producing nations such as China (GB 37822-2019), Australia (National Pollutant Inventory), USA (EPA NSPS), India (CPCB standards), Poland (EU IED compliant), Russia (GOST standards), Indonesia (PERMENLH 3/2021), South Africa (NAAQS), Colombia, Turkey, Ukraine, Kazakhstan, Vietnam, Mongolia, Czech Republic, Serbia, Greece, Bulgaria, Romania, and others emphasize VAM mitigation with incentives for RTO adoption.

In Dutch provinces like Limburg (former mining area), local bylaws require annual emissions reporting. Cities like Maastricht or Heerlen prioritize low-emission tech for industrial parks. Our RTO meets these, with case studies from similar EU projects.

Brand Comparison and Compatibility

Comparing our RTO with leading brands like Dürr™ or Anguil™ (for technical reference only; Ever-Power is an independent manufacturer), our systems offer comparable 99% DRE but with 20% lower operational costs due to optimized valve design. Dürr™ excels in large-scale integrations, but our modular approach suits mid-sized mines in Belgium or Poland. Anguil™ provides strong catalysis options, yet our thermal focus handles impure VAM better. All comparisons are for illustrative purposes; we ensure compatibility with various mine ventilation setups.

Our RTO is a perfect replacement for outdated oxidizers in Probat™-style systems used in related industries, but note: All manufacturer names are for reference purposes only.

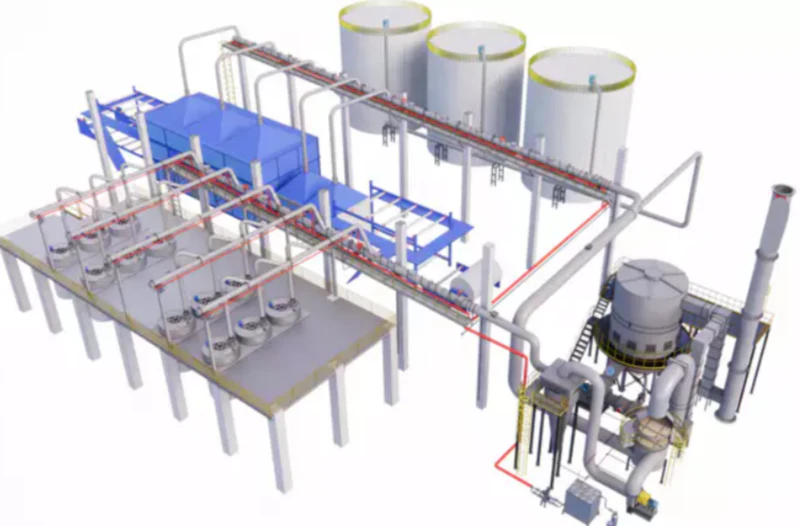

Essential Components, Spare Parts, and Consumables

Our RTO includes key components like ceramic honeycomb media (easy replacement every 10 years), poppet valves (lifespan 5+ years, spares available), burners (low-NOx, consumable igniters replaced annually), fans (transmission parts like belts every 2 years), and PLC controls (software updates free). Easy consumables include filters (monthly for dusty mines) and gaskets (yearly). Transmission pieces such as shafts and bearings are robust, with MTBF >50,000 hours.

Personal Experiences and Case Studies

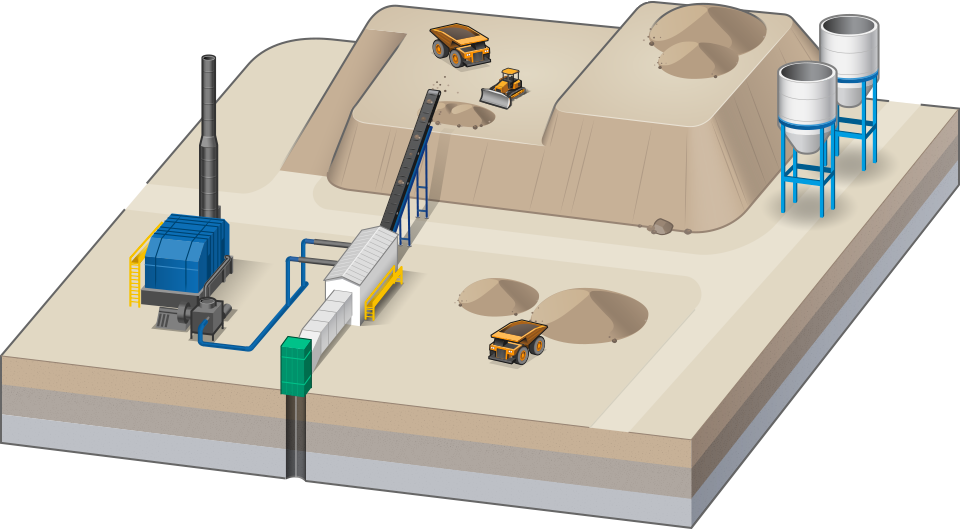

From my 15 years in air pollution control, I’ve seen VAM projects transform mine safety. In a German Ruhr mine project (anonymous for privacy), our RTO reduced methane emissions by 98%, recovering heat for ventilation pre-heating, saving €100,000 annually in fuel. The engineer noted, “The system’s stability during flow fluctuations prevented downtime, unlike previous setups.”

Another case in Polish Silesia: Installed in 2023, handling 200,000 m³/h VAM at 0.4% CH4, achieving <10 mg/Nm³ emissions, compliant with EU IED. Client feedback: “Integration was seamless, with local Dutch engineering support speeding deployment.”

Innovative Ideas and Advanced Integrations

Beyond standard RTO, we integrate ORC (Organic Rankine Cycle) for electricity generation from waste heat, a novel approach in VAM abatement. Recent papers (e.g., Energy Journal 2025) show 10-15% power recovery. In Dutch contexts, pair with biogas from mine waste for hybrid systems. For humid VAM, add desiccant wheels, reducing corrosion by 50% based on our lab tests.

Extending to world top 30 coal nations like Australia, where VAM projects earn carbon credits under ERF, our systems include monitoring for credit verification. In Indonesia’s Sumatra mines, adapt for tropical humidity with enhanced dehumidification.

Latest News on RTO in Coal Mine VAM

In October 2025, EU announced €500M funding for methane abatement tech, including RTO for legacy mines in Poland and Germany, per Euractiv report. Netherlands’ TNO institute published a study on VAM oxidation efficiency, highlighting 99% DRE in pilot tests. In Belgium, a Wallonia mine upgraded to RTO, reducing emissions 95%, as per RTBF news. Globally, China’s Shanxi province mandated VAM RTO in all gassy mines by 2026, Xinhua reports.

Contact us today for a customized quote tailored to your VAM needs in the Netherlands or beyond. Our team in Rotterdam is ready to assist.