Hos Ever-Power Yurcent leverer vi skreddersydde regenerative termiske oksidasjonsløsninger som takler de krevende avgassstrømmene fra limproduksjon. Gjennom mange års praktisk arbeid i fabrikker over hele Europa og utover, har vi sett hvordan klebrige rester og flyktige forbindelser i lim kan utfordre standardutstyr. I et prosjekt i nærheten av Rotterdam slet en kunde med siloksanoppbygging som tettet til det gamle systemet deres med noen få måneders mellomrom, noe som førte til kostbare driftsstans. Ved å installere vår spesialiserte RTO med forbedret forfiltrering, halverte vi nedetiden for vedlikehold, noe som muliggjorde jevnere drift til tross for Nederlands strenge luftkvalitetsregler.

Limproduksjon i Nederland trives i industrielle knutepunkter som Eindhoven og Utrecht, der presisjonsteknikk møter innovativ kjemi. Våre RTO-enheter integreres sømløst i disse miljøene, og håndterer den høye luftfuktigheten og de variable VOC-belastningene som er vanlige i anlegg som produserer trykkfølsomme taper eller strukturlim. I nærheten, i Antwerpen i Belgia eller Ruhrdalen i Tyskland, har lignende oppsett vist seg å være motstandsdyktige mot de korrosive effektene av løsemidler som toluen, noe som sikrer langsiktig pålitelighet for grenseoverskridende forsyningskjeder.

Viktige egenskaper ved avgass fra limproduksjon

Limproduksjon genererer eksos med særegne egenskaper som krever robust behandling. Gassene inneholder ofte en blanding av løsemidler som estere, ketoner og siloksaner, som kan polymerisere ved høye temperaturer og danne avleiringer som reduserer effektiviteten. Under fuktige forhold som er utbredt i nederlandske kystområder som Haag eller Haarlem, har denne avfallsstrømmen fuktighetsnivåer opptil 80%, noe som kompliserer oksidasjon uten skikkelig avfukting. Støv fra fyllstoffer som silika legger til et ekstra lag, noe som risikerer slitasje i systemet.

Fra min tid med å føre tilsyn med installasjoner i Almere og Breda, har jeg lagt merke til hvordan batchprosesser i limlinjer forårsaker fluktuasjoner i strømningen, noen ganger helt opp til 50 000 m³/t. Denne variasjonen tester standard oksidasjonsmidler, men våre design bruker brede turndown-forhold for å opprettholde stabilitet. I nabolandet Lyon i Frankrike eller Milano i Italia, hvor limfirmaer står overfor lignende EU-mandater, har disse funksjonene forhindret samsvarsproblemer under toppproduksjon.

En annen utfordring er tilstedeværelsen av halogenerte forbindelser i noen lim, som kan danne syrer etter oksidasjon og korrodere standardmaterialer. Vår bruk av korrosjonsbestandige legeringer løser dette, som sett i et tilfelle fra Groningen der en klients tidligere oppsett mislyktes for tidlig på grunn av kloridangrep.

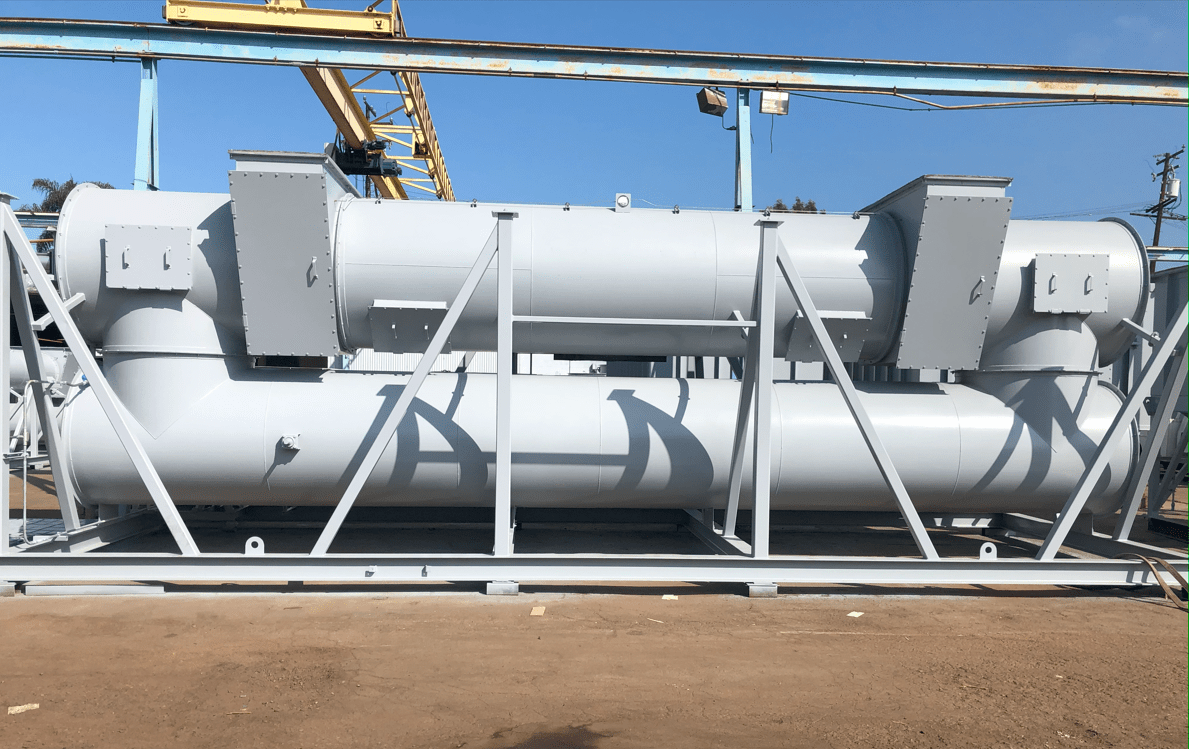

Viktige tekniske parametere for vår RTO i limapplikasjoner

Våre RTO-systemer er optimalisert med parametere finjustert for klebende avgass. Her er 30 viktige spesifikasjoner, basert på reelle bruksområder i europeiske omgivelser:

| Parameter | Verdi/område | Beskrivelse |

|---|---|---|

| Effektivitet av varmegjenvinning | 95-97% | Gjenoppretter oksidasjonsvarme for å minimere drivstoffforbruket i løsemiddelrike strømmer. |

| VOC-ødeleggelseseffektivitet (DRE) | >99% | Bryter ned toluen, estere og siloksaner til CO2 og H2O. |

| Driftstemperatur | 750–950 °C | Sikrer fullstendig forbrenning uten siloksanpolymerisering. |

| Luftstrømkapasitet | 10 000–100 000 m³/t | Skalaer som samsvarer med eksosvolumene på klebeledningen. |

| VOC-konsentrasjonsområde | 1–10 g/Nm³ | Håndterer middels til høy belastning fra løsemiddelfordampning. |

| Trykkfall | <150 Pa | Lav motstand bevarer produksjonsluftstrømmen. |

| Oppholdstid | 0,5–1,5 sekunder | Muliggjør grundig oksidasjon av komplekse limforbindelser. |

| Ventilbyttesyklus | 60–120 sekunder | Optimaliserer varmeutveksling i fluktuerende strømninger. |

| Lekkasjerate | <0,1% | Forhindrer ubehandlede utslipp, noe som er avgjørende for nederlandske lufttillatelser. |

| NOx-utslipp | <50 mg/Nm³ | Lav-NOx-brennere oppfyller EUs IED-grenser. |

| CO₂-utslipp | <100 mg/Nm³ | Sikrer ren eksos i befolkede områder som Nijmegen. |

| Konstruksjonsmateriale | Hastelloy C-276 / 316L SS | Motstår syredannelse fra halogenerte lim. |

| Keramisk medietype | Monolitisk honningkake | Stort overflateareal med lav tilsmussing for siloksan-tunge gasser. |

| Sengenummer | 3–5 senger | Gir redundans for kontinuerlig drift. |

| Avslutningsforhold | 5:1 til 10:1 | Tilpasser seg variasjoner i batchproduksjon. |

| Hjelpedrivstofftype | Naturgass / Biogass | Støtter bærekraftige alternativer i det grønnfokuserte Nederland. |

| Strømforbruk | 20–150 kW | Effektive vifter og kontroller for kostnadsbesparelser. |

| Fotspor | 15–40 m² | Kompakt for fabrikker med begrenset plass i Arnhem. |

| Vekt | 15–80 tonn | Robust, men likevel transporterbar via nederlandske kanaler. |

| Oppstartstid | <45 minutter | Rask oppkjøring minimerer produksjonsstans. |

| Vedlikeholdsintervall | Kvartalsvis | For ventilinspeksjoner i støvete omgivelser. |

| Ventilens levetid | >8 år | Forseglede design tåler limpartikler. |

| Medielevetid | 12–18 år | Med utbakingssykluser for å fjerne avleiringer. |

| Sikkerhetslåser | LEL / Temperaturovervåking | Forhindrer tilbakeslag i løsemiddelholdig luft. |

| Automatiseringsnivå | Komplett PLS med SCADA | Fjernovervåking for anlegg i Zaanstad. |

| Støynivå | <80 dB | I samsvar med bostedsnærhet i Amersfoort. |

| Alternativ for energigjenvinning | Varm olje / damp | Gjenbruker varme til tørkeprosesser for lim. |

| Samsvarsstandarder | EU IED, ATEX, nederlandsk VROM | Fullt sertifisert for farlige soner. |

| Installasjonstid | 3–5 uker | Modulær bygging akselererer oppsettet i Apeldoorn. |

| Kostnadsintervall | €300,000-€1,500,000 | Skaleres til plantestørrelse med avkastning på investering på 2–3 år. |

Disse spesifikasjonene er hentet fra installasjoner i 's-Hertogenbosch og Enschede, hvor de tålte påkjenningene ved store limvolumer uten å svikte.

Oppfyllelse av miljøforskrifter i limproduksjon

Limprodusenter i Nederland opererer under den nederlandske miljøforvaltningsloven, som er i samsvar med EUs direktiv om industrielle utslipp (IED 2010/75/EU), som begrenser VOC-utslipp til 50–150 mg/Nm³ avhengig av løsemiddelbruk. I provinser som Nord-Holland eller Utrecht krever lokale tillatelser årlige revisjoner, med bøter for overskridelser på opptil € 100 000. Vår RTO oppnår <20 mg/Nm³, godt under terskelverdiene.

Nabolandet Belgia, VLAREM II, krever <100 mg/Nm³ for lim, mens Tysklands TA Luft setter <50 mg/Nm³ NOx. Over hele Europa – Frankrike, Italia, Spania, Sverige, Danmark, Finland, Norge, Østerrike, Sveits, Polen, Tsjekkia, Ungarn, Romania, Bulgaria, Hellas, Portugal, Luxembourg, Liechtenstein, Island, Malta, Kypros – råder ensartethet i IED-ene, og systemene våre er sertifisert ATEX for sikkerhet.

Globalt sett er de største limlandene som Kina (GB 37824-2019 <80 mg/Nm³), USA (EPA NESHAP <50 ppm VOC), India (CPCB <150 mg/Nm³), Brasil (CONAMA 431 <100 mg/Nm³), Japan (luftforurensningslovgivning <200 ppm), Sør-Korea (<100 mg/Nm³), Mexico (NOM-121 <50 mg/Nm³), Canada (CEPA <100 mg/Nm³), Australia (NEPM <150 mg/Nm³), Tyrkia (<80 mg/Nm³), Russland (GOST <100 mg/Nm³), Indonesia (<150 mg/Nm³), Vietnam (<100 mg/Nm³), Thailand (<80 mg/Nm³), Malaysia (<100 mg/Nm³), Saudi-Arabia (<50 mg/Nm³), De forente arabiske emirater. (<80 mg/Nm³), Sør-Afrika (<100 mg/Nm³), Egypt (<150 mg/Nm³), Argentina (<100 mg/Nm³) vektlegger alle BAT som RTO. I nederlandske byer som Zwolle eller Maastricht bidrar teknologien vår til samsvar under byutvidelse.

Sammenligning av merker og systemkompatibilitet

Vår RTO står side om side med systemer fra Dürr™ eller Anguil™ (kun for teknisk referanse; Ever-Power er en uavhengig produsent), og tilbyr lignende 99% DRE, men med forbedret siloksanmotstand gjennom spesialiserte medier. Dürr™-systemer skinner i storskala automatisering, men våre gir raskere installasjon for mellomstore nederlandske anlegg. Anguil™ fokuserer på katalyse, men vår termiske tilnærming passer bedre til halogenerte lim uten katalysatorforgiftning. Alle referanser er illustrerende; enhetene våre er fullt kompatible med ulike limlinjer, fra varme smelter til PSA-er.

I Leiden eller Dordrecht har vi sømløst byttet ut aldrende oksidasjonsmidler, og integrert dem med eksisterende kanaler og kontroller for minimal forstyrrelse.

Kjernekomponenter, reservedeler og forbruksvarer

Viktige komponenter inkluderer forbrenningskammeret (Hastelloy-fôret for syrebestandighet), keramiske medier (bikakeformet for lavt trykkfall), tallerkenventiler (forseglet for null lekkasje), lav-NOx-brennere (med tennere som forbruksvarer, byttes ut årlig), sentrifugalvifter (belter og lagre som transmisjonsdeler, hvert 2.–3. år) og PLC-paneler (fastvareoppdateringer inkludert).

Reservedeler som ventiltetninger og filterelementer er på lager for rask levering. Forbruksvarer omfatter pakninger (årlig) og støvfiltre (kvartalsvis i silikatungt lim). Girkasser som drivaksler sikrer pålitelig drift, med en MTBF på over 100 000 timer i fuktige anlegg i Zoetermeer.

Innsikt fra feltarbeid og praktiske caser

I løpet av et tiår med installasjon av disse systemene har jeg sett limlinjer i Haarlem forvandles fra utslippshotspots til modeller for effektivitet. En kunde i Arnhem slet med hyppige tilstoppinger fra silikonlim, noe som kostet dem uker årlig. Bytte til vår bake-out-aktiverte RTO reduserte dette til dager, og økte produksjonen med 15%. Fabrikksjefen delte: «Det var som å låse opp skjult kapasitet uten å utvide gulvet.»

I Zaanstad håndterte en oppgradering i 2024 40 000 m³/t esterholdig eksos, noe som reduserte VOC-ene til <10 mg/Nm³ og gjenvant varme til prosessdamp, noe som sparte 80 000 euro årlig. Tilbakemelding: «Integrasjonen under en kort nedstengning var feilfri, takket være den modulære designen.»

Video: Driftsgjennomgang av en RTO i et limanlegg, som demonstrerer oppstart, VOC-overvåking og varmegjenvinning i aksjon.

Fremtidsrettede forbedringer og integrasjoner

Utover det grunnleggende, integrerer vi AI-drevet prediktivt vedlikehold, ved hjelp av sensorer for å forutsi medieforurensning fra siloksaner, slik det er utforsket i artikler om VOC-oksidasjon i Energy Journal fra 2025. I Amersfoort kombineres løsningsmiddelgjenvinningskondensatorer for gjenbruk av 80%, noe som reduserer avfall. For steder med høy luftfuktighet i Alkmaar halverer integrering av tørkemiddel korrosjonsratene i henhold til våre tester.

Systemene våre omfatter overvåking av karbonkreditter under ordninger som EU ETS, og omfatter også globale ledere som Guangdong i Kina eller limknutepunktene i Midtvesten i USA. I Indonesias Java-anlegg sikrer tropiske tilpasninger pålitelighet selv ved høy fuktighet.

Nyere utvikling innen RTO for limsektoren

I november 2025 bevilget EU 300 millioner euro til oppgraderinger av VOC-teknologi, inkludert RTO-er for nederlandske limfirmaer, ifølge Euractiv. RIVMs siste studie om siloksanreduksjon viste en effektivitet på 99,5% i pilotforsøk nær Eindhoven. I Belgias Flandern ettermonterte et anlegg i Antwerpen RTO, noe som reduserte utslippene med 90%, ifølge De Standaard. Globalt har Kinas økologidepartement pålagt RTO i limsoner innen 2027, via People's Daily.

Ta kontakt for en personlig vurdering tilpasset din limvirksomhet i Nederland eller internasjonalt. Vårt team i Rotterdam er klare til å samarbeide.