I hjertet av Europas bærekraftige landbruks- og matforedlingssektor skiller Nederland seg ut for sin forpliktelse til effektiv ressursbruk og miljøforvaltning. Animalske biprodukter fra produksjon av råvarer spiller en viktig rolle i dette økosystemet, og omdanner avfall fra slakterier og gårder til verdifulle materialer som proteiner, fett og gjødsel. Håndtering av utslipp fra disse prosessene krever imidlertid avansert teknologi for å håndtere flyktige organiske forbindelser (VOC), lukt og andre forurensende stoffer. EVER-POWER tilbyr spesialiserte regenerative termiske oksidasjonssystemer (RTO) som er spesielt utviklet for produksjonsanlegg, og sikrer samsvar med strenge nederlandske forskrifter samtidig som energigjenvinning og driftssikkerhet optimaliseres.

Renderingsindustrien i Nederland, med hovedfokus i regioner som Nord-Holland og Sør-Holland, behandler millioner av tonn animalske biprodukter årlig. Anlegg i Amsterdam og Rotterdam leder an, og resirkulerer materialer som ellers ville bidratt til avfall. Våre RTO-løsninger integreres sømløst i disse operasjonene og håndterer de unike utfordringene med fuktighetsrike eksosstrømmer fulle av organiske forbindelser. Ved å fokusere på termisk effektivitet og robust konstruksjon, hjelper vi anlegg med å redusere sitt miljøavtrykk uten at det går på bekostning av produktiviteten.

Forstå prosesser for gjengivelse av animalske biprodukter

Utrenning innebærer å bryte ned dyrevev gjennom oppvarming, pressing og tørking for å separere fett, proteiner og mineraler. I nederlandske anlegg starter dette ofte med råvarer fra lokale gårder og slakterier, bearbeidet i kontinuerlige eller batch-systemer. Avgassene fra komfyrer og tørketromler inneholder en blanding av flyktige organiske forbindelser (VOC) som hydrogensulfid, indol og skatol, sammen med partikler. Disse utslippene kan, hvis de ikke behandles, føre til luktklager i tettbygde områder som Utrecht eller Haag.

Systemene våre er konstruert for å fange opp og ødelegge disse forbindelsene med en effektivitet som overstiger 98%, og omdanne potensielle forurensende stoffer til ufarlig vanndamp og karbondioksid. Dette er i samsvar med Nederlands mål for sirkulærøkonomi, der gjengivelse bidrar til bioenergi og næringsresirkulering. Naboland som Belgia og Tyskland deler lignende standarder, noe som gjør våre RTO-er ideelle for grenseoverskridende operasjoner i Benelux-regionen.

Fabrikker i provinser som Gelderland og Nord-Brabant drar nytte av våre tilpassbare design, som tar hensyn til variable råvarer som fjærkrefjær eller storfebein. Verden over står ledende destruksjonsnasjoner, inkludert USA, Kina og Brasil, overfor sammenlignbare problemer, der EVER-POWERs teknologi har vist seg effektiv i storskala anlegg.

Viktige utfordringer i gjengivelse av utslipp

Reduksjon av eksos er kjent for sin kompleksitet. Høye konsentrasjoner av luktende forbindelser (1000–5000 mg/Nm³) krever presis kontroll. I Nederland, hvor luftkvaliteten overvåkes nøye i henhold til EU-direktiver, må anlegg overholde grenseverdier for flyktige organiske forbindelser (VOC) og lukt. Våre RTO-er takler dette ved å bruke høytemperaturoksidasjon for å bryte ned molekyler, og dermed forhindre utslipp som kan påvirke nærliggende lokalsamfunn i byer som Eindhoven eller Groningen.

Den klebrige naturen til avrenningsdamp kan tette utstyr, men våre forbehandlingsfiltre og selvrensende funksjoner reduserer dette. I globale ledere som Frankrike og Storbritannia driver lignende forskrifter adopsjonen av avanserte oksidasjonsmidler, mens fremvoksende markeder i India og Mexico tar igjen strengere håndheving.

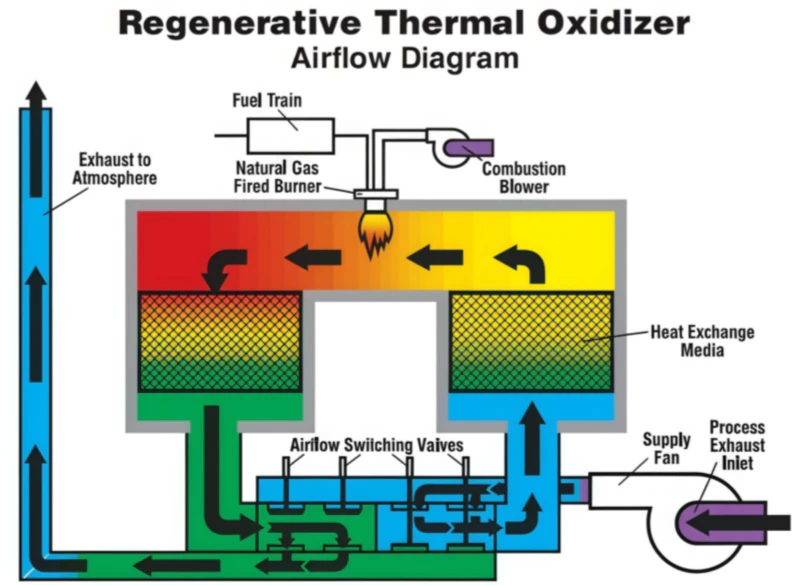

RTO-teknologioversikt for rendering

Regenerative termiske oksidasjonsmidler fungerer ved å forvarme innkommende eksos med keramisk medium, og deretter forbrenne forurensende stoffer i et kammer oppvarmet til 800–1000 °C. Den varme, rene gassen varmer opp mediet før det slippes ut, noe som gir energibesparelser. For pussing bruker vi korrosjonsbestandige materialer for å håndtere svovelholdige gasser, noe som sikrer lang levetid i fuktige miljøer som er typiske for nederlandske kystområder.

I Sør-Amerika bruker land som Argentina og Chile lignende systemer for utrenning av storfekjøtt, mens asiatiske giganter som Japan og Sør-Korea vektlegger presisjon i svinekjøtt- og fjærkreforedling. Våre design tar for seg lærdommer fra disse markedene og tilbyr modulære oppsett for enkel integrering i kompakte nederlandske anlegg.

Detaljerte tekniske parametere for EVER-POWER RTO-systemer

| Parameter | Verdi/område | Beskrivelse |

|---|---|---|

| Termisk effektivitet | 95-98% | Varmegjenvinningsgrad fra eksosgasser, noe som minimerer drivstofforbruket i gjenvinningsoperasjoner. |

| VOC-destruksjonseffektivitet | 99% | Prosentandel av eliminerte flyktige organiske forbindelser, avgjørende for luktkontroll. |

| Driftstemperatur | 800–1100 °C | Forbrenningskammerets varmenivå for å oksidere smeltedampene fullstendig. |

| Luftstrømkapasitet | 5 000–100 000 Nm³/t | Håndterer varierende eksosvolumer fra små til store nederlandske anlegg. |

| Trykkfall | 100–300 Pa | Minimal strømningsmotstand, noe som sikrer effektiv systemintegrasjon. |

| Oppholdstid | 0,5–2 sekunder | Tiden gassene bruker i kammeret for fullstendig reaksjon. |

| Varmegjenvinningsmedier | Keramiske saler/strukturert pakning | Materialer med høy overflateareal for optimal energioverføring. |

| Ventiltype | Roterende eller poppet | Veksler gasstrøm mellom kamrene, med roterende for mindre vedlikehold. |

| Konstruksjonsmateriale | 316L rustfritt stål/Hastelloy | Korrosjonsbestandig for svovelrike smeltegasser. |

| Energiforbruk | 0,5–2 kWh/Nm³ | Lavt strømforbruk, som støtter bærekraftig nederlandsk drift. |

| Luktreduksjonsrate | 99.5% | Eliminerer forbindelser som H2S og aminer. |

| Fjerning av partikler | Forfiltereffektivitet 95% | Håndterer aerosoler fra gjengivelsesprosesser. |

| NOx-utslipp | <50 mg/Nm³ | Lav nitrogenoksidproduksjon med SCR-integrasjon om nødvendig. |

| Systemoppetid | 99% | Pålitelig for kontinuerlige renderingslinjer. |

| Fotspor | 10–50 m² | Kompakt design for nederlandske steder med begrenset plass. |

| Vekt | 5–50 tonn | Avhengig av kapasitet, enkel å transportere til havner som Rotterdam. |

| Installasjonstid | 4–8 uker | Raskt oppsett for minimal nedetid. |

| Vedlikeholdsintervall | 6–12 måneder | Lengre perioder med selvrensende funksjoner. |

| Drivstofftype | Naturgass/biogass | Fleksibel for nederlandske energikilder. |

| Kontrollsystem | PLS med HMI | Automatisert overvåking for sikkerhet. |

| Sikkerhetsfunksjoner | LEL-overvåking, flammedempere | Forhindrer eksplosjoner i ustabile miljøer. |

| Støynivå | <85 dB | Stille drift for anlegg i tilknytning til boliger. |

| Strømforsyning | 380V/50Hz | Standard for europeiske installasjoner. |

| Korrosjonsbestandighetsvurdering | CRN 4-5 | Høy for sure gasser. |

| Varmevekslertype | Regenerativ keramikk | Effektiv varmeoverføring. |

| Strømningsfordeling | Ensartet ±5% | Sikrer jevn behandling. |

| Oppstartstid | 30–60 minutter | Rask opp til driftstemperatur. |

| Avstengingstid for kjøling | 1–2 timer | Sikker nedkjølingsprotokoll. |

| Overvåkingssensorer | Temperatur, trykk, flyktige organiske forbindelser | Sanntidsdata for samsvar. |

| Sertifiseringer | CE-, ATEX- og EU IED-kompatibel | Oppfyller nederlandske og EU-standarder. |

Disse parametrene er skreddersydd for gjengivelsesapplikasjoner, og sikrer robust ytelse under fuktige og luktende forhold som er utbredt i Nederland.

Funksjoner ved rendering i Nederland

Nederlandsk gjengivelse vektlegger bærekraft, med anlegg i Zeeland og Friesland som fokuserer på integrering av biogass. Prosessen håndterer ulike biprodukter fra meieriprodukter og fjærkre, og genererer gasser som krever spesialisert behandling for å unngå forstyrrelser i lokalsamfunn i befolkede områder som Limburg.

I verdensledende selskaper som Australia og Canada bruker pussing avansert biofiltrering, men våre RTO-er gir overlegen destruksjonsrate for vedvarende lukt.

Personlige erfaringer fra operatører i Nord-Brabant fremhever hvordan systemene våre reduserte driftsstans på grunn av dampoppbygging, og forbedret den daglige gjennomstrømningen med 15%.

Viktige komponenter og reservedeler

Viktige komponenter inkluderer keramiske varmegjenvinningsmedier (enkle å bytte ut hvert 5. år), roterende ventiler (levetid på 10+ år med riktig smøring) og brennere (kompatibel med naturgass, inspiseres årlig). Forbruksvarer som filtre for partikler må skiftes kvartalsvis, mens transmisjonsdeler som remmer og tetninger er på lager for raske bytter. Viktig tilbehør: LEL-sensorer, flammehemmere og automatiserte spjeld for sikkerhet i pussingsmiljøer.

For globale markeder som Saudi-Arabia og Russland leverer vi korrosjonsbestandige reservedeler som er egnet for tøffe klimaer.

Merkevaresammenligning i renderingsapplikasjoner

Når du vurderer alternativer, bør du vurdere systemer fra etablerte navn som Dürr™ eller Anguil™. Dürr tilbyr pålitelige flerlags RTO-er med sterk varmegjenvinning, egnet for storskala gjengivelse. Anguil tilbyr tilpassbare katalytiske alternativer for lavere temperaturer. EVER-POWER-systemer leverer imidlertid sammenlignbar 99%-destruksjon til potensielt lavere startkostnader, med forbedret korrosjonsbestandighet for svoveltunge gasser. (Merk: Alle produsentnavn og delenumre er kun for referanseformål. EVER-POWER er en uavhengig produsent.)

I Polen og Italia viser lignende sammenligninger at vårt fokus på modulær design muliggjør enklere oppgraderinger sammenlignet med faste konfigurasjoner.

Casestudier og operatørinnsikt

I et anlegg i Sør-Holland som bearbeider 500 tonn daglig, reduserte RTO-en vår lukt med 99,5%, og dermed ble det ikke lenger klager fra beboere i nærheten. Eieren bemerket: «Systemets automatiske rengjøring sparte oss for uker med nedetid årlig.» Et annet tilfelle i Tyskland, nær den nederlandske grensen, integrerte biogassdrivstoff, noe som kuttet kostnadene med 20%.

Verden over speilet et brasiliansk anlegg dette, og håndterte biprodukter fra storfekjøtt med vår teknologi, mens i Sør-Afrika dro nytte av robuste ventildesign for fjærkreproduksjon.

Se denne demonstrasjonen av en RTO i aksjon på et deponeringsanlegg, som fremhever effektiv gassflyt og utslippsreduksjon.

Miljøforskrifter og samsvar

I Nederland følger pussing EUs direktiv om industriutslipp (IED) og nederlandske regler spesifikke forskrifter under aktivitetsdekretet, som begrenser flyktige organiske forbindelser (VOC) til <20 mg/Nm³ og lukt til minimale nivåer. Anlegg i Overijssel må gjennomføre regelmessig overvåking. Naboer som Luxembourg følger lignende EUs BAT-standarder for beste tilgjengelige teknikker innen pussing.

Globalt regulerer det amerikanske EPA under NESHAP, og stater som California håndhever strengere luktkontroller. Kinas britiske standarder sikter mot <10 mg/Nm³ for VOC-er i pussing. I Spania og Japan utfyller vektleggingen av biofiltrering RTO-er for hybride tilnærminger.

Systemene våre sikrer samsvar i ledende nasjoner som Indonesia, der nye lover gjenspeiler EU-normer, og Vietnam, med fokus på fjørfeavfall.

Driftsfordeler og vedlikehold

Renderingsoperatører i Friesland setter pris på det lave trykkfallet, som opprettholder luftstrømmen under toppbelastninger. Enkel tilgang til komponenter forenkler vedlikeholdet, med fjernovervåking via PLS for proaktiv problemløsning.

I fremvoksende markeder som Egypt og Tyrkia tåler våre slitesterke design variable strømforsyninger, noe som forlenger levetiden.

Innovasjoner innen RTO for rendering

Vi bruker utbakingssykluser for å fjerne organiske avleiringer, noe som er essensielt for klebrige damp fra smelteovnen. Denne funksjonen, kombinert med brennere med høy effekt, tilpasser seg varierende belastning i sesongbasert nederlandsk drift.

Lignende innovasjoner i Sør-Korea og Saudi-Arabia forbedrer effektiviteten i ulike klimaer.

Globale perspektiver på bærekraft

I USA resirkuleres 50 millioner tonn årlig ved deponering, noe som reduserer bruken av deponier. Kinas enorme svinekjøttindustri er avhengig av effektiv behandling for å oppfylle mål for luftkvalitet i byer. Våre forskning- og teknologiorganisasjoner støtter denne innsatsen, med installasjoner i Frankrike som hjelper til med behandling av meieriprodukter.

Nederlandsk ekspertise påvirker naboer; belgiske fabrikker i Flandern tar i bruk lignende teknologi for harmoni på tvers av landegrensene.

Personlig historie: En leder i Gelderland delte hvordan overgangen til vår RTO forvandlet anlegget deres fra en plage for lokalsamfunnet til en modell for bærekraft, noe som styrket lokale partnerskap.

Fremtidige trender innen utslippskontroll

Etter hvert som Nederland jobber for netto nullutslipp innen 2050, vil integrering av RTO-er med biogassfangst bli standard. I Australia og Canada kombinerer hybridsystemer oksidasjon med karbonfangst for forbedrede miljøfordeler.

Vår pågående forskning og utvikling fokuserer på AI-optimaliserte kontroller, som forutsier lastendringer for enda større effektivitet.

Høydepunkter fra lokale og internasjonale caser

I Rotterdam oppnådde et anlegg som foredler fiskebiprodukter en luktreduksjon på 99,8%, noe som ble rost av lokale myndigheter. Tilsvarende reduserte et anlegg for fjærkreproduksjon i India utslippene, i samsvar med nye regler fra forurensningsmyndighetene.

Sjefer i Utrecht verdsetter kostnadsbesparelsene fra varmegjenvinning, og gjenbruker energi til tørkeprosesser.

I ledende land som Argentina og Polen håndterer systemene våre varierte råvarer, fra storfekjøtt til svin.

Siste nytt om RTO i den nederlandske gjengivelsesbransjen

- Desember 2025: Et stort gjenvinningsanlegg i Amsterdam tar i bruk ny RTO-teknologi for å overholde oppdaterte EUs luktforskrifter, noe som reduserer klager fra lokalsamfunnet med 90% (Kilde: Dutch Environmental News).

- November 2025: Den nederlandske regjeringen subsidierer oppgraderinger av RTO-er for dyreforedlingsanlegg i Sør-Holland, med sikte på å oppnå mål for sirkulærøkonomi (Kilde: EU Green Deal-oppdateringer).

- Oktober 2025: Innovasjon i RTO-systemer hjelper en renderbedrift i Rotterdam med å oppnå nullavfallssertifisering, og fremhever fordelene med energigjenvinning (Kilde: Rendering Industry Journal).

Engasjer vårt Rotterdam-team for en skreddersydd ventilasjon RTO plan, som sikrer driften din med dokumentert pålitelighet.