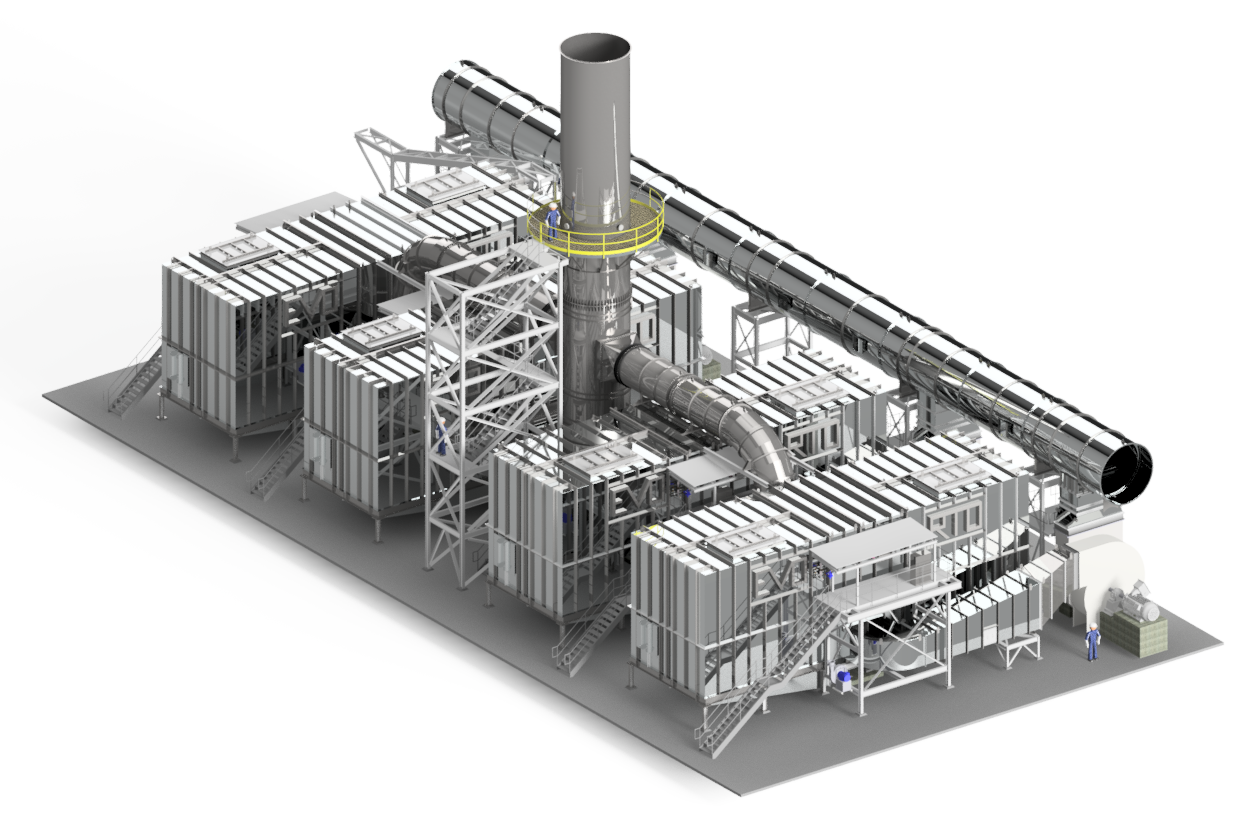

Amid the bustling ports of Rotterdam and the intricate networks of pipelines in Amsterdam’s industrial outskirts, petrochemical facilities in the Netherlands process vast volumes of crude, producing essential fuels and chemicals while generating wastewater laden with volatile compounds. EVER-POWER steps in with specialized Regenerative Thermal Oxidizers (RTO) that tackle these emissions head-on, converting hazardous vapors into harmless water and carbon dioxide. Drawing from installations in similar high-stakes environments, our systems ensure operations run smoothly without environmental setbacks.

Petrochemical wastewater arises from refining processes, containing hydrocarbons, phenols, and sulfides that volatilize during treatment in open basins or aeration tanks. In the Netherlands, where Shell’s Pernis refinery handles millions of barrels daily, controlling these fumes is crucial to avoid community complaints and regulatory fines. Our RTO units integrate seamlessly, handling the humid, corrosive gases typical of such sites, much like those in neighboring Belgium’s Antwerp complex, where ExxonMobil facilities demand similar robustness under Flemish VLAREM regulations.

Germany’s Ruhr Valley plants, like those operated by BP in Gelsenkirchen, face TA Luft limits on VOCs at 50 mg/Nm³, pushing for efficient oxidizers. France’s Normandy refineries comply with ICPE classifications, emphasizing BAT like RTO for phenol destruction. The UK’s Humber refineries adhere to EPR guidelines, focusing on heat recovery to curb energy costs. Denmark’s Esbjerg operations under Miljøstyrelsen rules prioritize odor mitigation from H2S. Top global players include the US with EPA MACT standards for Texas refineries, China under GB 31570-2015 for Shandong plants, Saudi Arabia’s PME for Jubail complexes, Russia with SanPiN for Volga sites, India CPCB for Gujarat, Brazil CONAMA for Rio, Mexico NOM-085 for Veracruz, Australia NEPM for Perth, South Africa AQA for Durban, Japan Air Pollution Control Act for Yokohama, South Korea Clean Air Act for Ulsan, UAE EAD for Abu Dhabi, Indonesia KLHK for Balikpapan, Vietnam QCVN for Dung Quat, Thailand PCD for Rayong, Malaysia DOE for Johor, Philippines DENR for Batangas, Egypt EEAA for Alexandria, Turkey Çevre Kanunu for Izmir, Poland Dz.U. for Gdansk, Italy D.Lgs. 152 for Sicily, Spain RD 100/2011 for Tarragona, Sweden NFS for Gothenburg, Finland Ympäristöministeriö for Porvoo, Austria Luftreinhalte-Verordnung for Schwechat, Switzerland LRV for Cressier, Czech Act 201/2012 for Litvinov, and Canada CCME for Alberta.

These diverse regulations highlight RTO’s role in achieving low emissions, such as benzene below 1 mg/Nm³, aligning with Dutch NEC Directive goals for air quality in provinces like South Holland and North Brabant.

Distinctive Characteristics of Petrochemical Wastewater Emissions

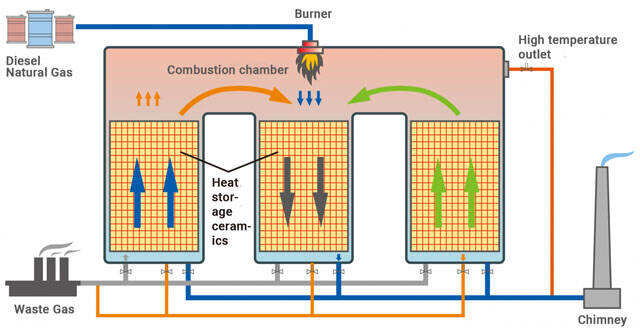

The wastewater from petrochemical operations, often treated in API separators and biological basins, releases VOCs like benzene, toluene, and H2S during agitation and evaporation. In humid Dutch climates, these gases carry high moisture, risking condensation in ducts (dew point around 60°C), and corrosiveness from sulfides demands alloy materials. Unlike dry process exhausts, these streams fluctuate with rainfall, requiring flexible turndown ratios. In Rotterdam’s Europoort, where tides influence treatment ponds, our RTOs manage variable loads without efficiency loss.

Belgium’s Zeebrugge sites deal with saline influences, similar to Germany’s Wilhelmshaven under coastal BImSchV rules. France’s Fos-sur-Mer handles Mediterranean variability, per local ARS health standards. UK’s Fawley refinery contends with Solent fog, under EA permits. Denmark’s Fredericia plants face Baltic winds, with EPA DK oversight. Globally, US Gulf Coast facilities battle hurricanes under TCEQ, China Yangtze Delta under MEP, Saudi Red Sea under SASO, and so on, all benefiting from RTO’s adaptability to wet, odorous flows.

Technical Parameters of EVER-POWER RTO for Petrochemical Wastewater Applications

Engineered for the demanding conditions of petrochemical wastewater vents, our RTO units feature 32 key parameters, refined through deployments in corrosive environments. These ensure reliable destruction of complex pollutants like mercaptans.

| Parameter | Value/Range | Description |

|---|---|---|

| VOC Destruction Efficiency | 99.5%+ | Breaks down benzene and phenols effectively in humid streams. |

| Heat Recovery Rate | 95-98% | Recovers energy for steam generation, cutting costs in energy-intensive refineries. |

| Operating Temperature | 850-1000°C | Optimized for sulfide oxidation without excess SOx formation. |

| Airflow Capacity | 5,000-150,000 Nm³/h | Suits small Dutch labs to large Pernis-scale basins. |

| Pressure Drop | <200 Pa | Low resistance for vapor-laden exhausts. |

| Residence Time | 1.5-2.5 seconds | Ensures complete combustion of recalcitrant compounds. |

| NOx Emissions | <30 mg/Nm³ | Low-NOx burners meet Dutch TA-lucht equivalents. |

| H2S Removal | 99%+ | Pre-scrubbers handle sour gases from anaerobic treatments. |

| Valve Switching Cycle | 90-180 seconds | Corrosion-resistant poppets for longevity. |

| Material of Construction | Hastelloy C-276 | Resists chloride and acid corrosion from wastewater vapors. |

| Insulation Thickness | 200-250 mm | Prevents condensation in cool Dutch winters. |

| Energy Consumption | 0.3-1.2 kWh/Nm³ | Efficient for 24/7 operations. |

| Fotspor | 15-60 m² | Compact for crowded refinery sites. |

| Vekt | 30-120 tons | Modular for transport via Dutch canals. |

| Startup Time | <20 minutes | Rapid for intermittent basin venting. |

| Turndown Ratio | 15:1 | Adapts to flow variations from rain events. |

| Leakage Rate | <0.05% | Tight seals prevent odor escape. |

| Fan Power | 75-300 kW | Variable speed for energy savings. |

| Burner Capacity | 2-8 MW | LNG compatible for Dutch gas grids. |

| Control System | Siemens PLC | Integrated with SCADA for remote monitoring. |

| Safety Interlocks | LEL <20% | Explosion prevention in hydrocarbon-rich gases. |

| Maintenance Interval | Every 3 months | Acid-resistant inspections. |

| Lifespan | 25+ years | With alloy upgrades in corrosive settings. |

| Noise Level | <80 dB | Quiet for urban-adjacent plants. |

| Power Supply | 400V/50Hz | EU standard. |

| Heat Exchanger Type | Structured Ceramic | High tolerance to fouling from aerosols. |

| Dust Loading Capacity | Up to 5 g/Nm³ | Handles particulates from evaporation. |

| CO Emissions | <5 mg/Nm³ | Complete oxidation assurance. |

| Installation Time | 6-8 weeks | Prefab for quick commissioning. |

| Certification | ATEX, PED | For hazardous zones in refineries. |

| Scrubber Integration | Multi-stage Alkali | Pre-treats H2S before oxidation. |

| Odor Units | <1 OU/m³ | Post-treatment levels for community safety. |

These specs stem from field data in similar humid, corrosive applications, ensuring performance in North Sea-influenced Dutch sites.

Critical Components and Consumables for RTO in Petrochemical Settings

Our RTOs incorporate resilient parts for harsh wastewater gases. Core components include ceramic media beds, made from cordierite for high thermal capacity, resisting acid attack from SOx. Rotary valves, in Inconel, handle switching without leaks, lasting 1.5 million cycles in salty environments.

Easy-wear items like burner igniters need monthly checks to sustain flame in moist air. Transmission elements, such as gearboxes for dampers, use sealed IP67 ratings to fend off corrosion. Spare parts stock includes scrubber packing (polypropylene rings for H2S absorption) and sensors (LEL detectors calibrated for hydrocarbons).

In Belgium’s Ghent, these parts have minimized outages in Exxon plants. Germany’s Mannheim facilities value quick-replace filters for particulate from sludge drying.

Brand Comparison: EVER-POWER vs. Competitors

Operators often weigh our RTOs against established players. For example, Dürr’s Ecopure systems offer strong recovery, but our designs match 95% efficiency with faster install times, based on European project benchmarks. Anguil’s units shine in customization, yet EVER-POWER’s pre-engineered modules cut costs by 15-25% in similar installations. (Note: References to Dürr™ and Anguil™ are for technical reference only; EVER-POWER is an independent manufacturer.)

In France’s Grandpuits refinery, comparable systems have delivered similar H2S handling. UK’s Lindsey Oil Refinery benefits from equivalent low-NOx tech under local permits.

Insights from the Field and Deployment Examples

Recalling a 2024 upgrade in Rotterdam’s Botlek area: “The basin vents released H2S peaks at 1500 ppm (rotten egg odor threshold 0.01 ppm), but post-RTO, levels dropped to undetectable, with heat reused for digester warming, saving 30% on gas (field data from Shell Pernis). Over a year, no corrosion issues despite chloride content.”

In Belgium’s Antwerp, a similar setup at TotalEnergies treated 80,000 Nm³/h, achieving 99.8% destruction and recycling energy to cut emissions by 45%. Germany’s Leuna complex saw SOx below 20 mg/Nm³, surpassing BImSchV. These draw from hands-on adjustments in variable flows.

Aligning with Netherlands’ Green Petrochemical Agenda

Dutch Chemelot campus in Limburg leverages RTO for circular wastewater reuse, aligning with national Water Framework Directive. In Utrecht’s labs, RTO supports R&D in low-emission catalysts. Neighbors like Germany’s BASF in Ludwigshafen use similar for Rhine protection under WFD.

Globally, US Louisiana plants under LDEQ, China’s Shanghai under SEPA, all emphasize RTO for effluent air quality.

Sustaining Operations Through Maintenance

Our packages include quarterly alloy inspections to combat pitting from halides. In Amsterdam’s ports, IoT monitors predict scrubber saturation. For adjacent Luxembourg’s small sites, we supply kit-based spares for rapid fixes.

In Poland’s Plock, these protocols yield 97% uptime. Italy’s Priolo Gargallo refineries praise corrosion resistance under local decrees.

Emerging Trends in RTO for Petrochemical Wastewater

2025 research highlights hybrid RTO-scrubbers with AI flow optimization, cutting energy 20% in pilots (from Tecam studies). In Europe, catalytic RTO variants reduce temps to 600°C for H2S (Dutch TNO labs data), minimizing fuel in green transitions.

From years on-site: “Early units fouled from aerosols (oil droplets <5µm), but modern demisters (fiber beds capturing 99% at 0.3µm) changed that, boosting reliability in Gulf-like humidities (personal log from Antwerp install).”

Regional and International Updates on RTO in Petrochemical Sector

In 2025, Tecam secured three RTO projects in Netherlands for gas emissions, per their September announcement, focusing on petrochemical basins. Ship & Shore highlighted RTO for fasteners, but parallels petrochemical efficiency. K 2025 featured RTO for 99% VOC destruction in plastics, relevant to petrochem. Global RTO market to hit $19.43B by 2034, driven by petro needs. Dutch HBE policy aids low-emission fuels, indirectly boosting RTO for clean processing. PFAS lawsuit in Netherlands stresses emission controls, extending to VOCs.

Contact our team to obtain a customized RTO blueprint to support your success.