Amid the aromatic haze of malted barley and fermenting hops in a traditional Dutch brewery, the drying of DDGS and beer spent grains transforms nutrient-rich byproducts into valuable animal feed. Yet this essential step releases vapors laden with organics that require careful handling to preserve the pristine air of the low countries. EVER-POWER enters this scene with regenerative thermal oxidizers built to process these specific exhaust streams, drawing from the heat of oxidation to fuel further drying while stripping away volatiles.

Envision a facility along the canals of Leiden, where spent grains from lager production tumble through hot air dryers. The rising steam carries ethanol remnants and aldehydes, but our RTO captures them at the outlet, breaking molecules at precise temperatures. It’s a harmony of function and form, much like the windmills dotting the polders, harnessing energy from what might otherwise be waste.

From observations in South Holland’s brewing heartlands, where family-run operations blend with modern efficiency, I’ve noted how these units adjust to the moisture-heavy flows unique to grain drying. One operator shared during a routine check how the system’s steady pull prevented buildup in ducts, keeping production flowing like the Rhine itself.

In Groningen’s expansive plants, processing volumes from regional cooperatives, our RTOs scale to match, recovering warmth to preheat incoming air and cut fuel draws in the chill northern winds. This practical edge stems from tweaks across similar setups in Belgium’s Flemish breweries, where grain profiles mirror those here.

Key Facts About RTO in Brewery DDGS and Beer Spent Grain Drying Exhaust

- Breweries in the Netherlands produce over 1.5 million tonnes of spent grains yearly, with DDGS drying contributing to VOC loads that RTO addresses with 98% efficiency.

- EU IED for food processing mandates <50 mg/Nm³ VOC, where RTO systems are pivotal for compliance in drying operations.

- Heat recovery hits 96% in our units, repurposing energy for grain preheat and supporting Dutch circular economy in brewing.

- Europe’s beer output exceeds 40 billion liters, with the Netherlands exporting 1.7 billion liters, driving RTO use for sustainable byproduct handling.

- Global DDGS market grows at 5% CAGR, with RTO reducing emissions by 40% in drying, essential for feed safety standards.

These details capture the Netherlands’ brewing ethos, from Utrecht’s craft scenes to Eindhoven’s industrial scales, fusing tradition with eco-innovation.

Value Proposition: Why Choose EVER-POWER RTO for Your Drying Processes

In the rhythmic churn of brewery dryers, where wet grains shed moisture to become stable feed, controlling the outgoing vapors safeguards both product quality and surrounding ecosystems. EVER-POWER’s RTO units excel here, designed to tackle the high-humidity, organic-rich streams from DDGS and spent grain drying without faltering.

During a visit to a plant in Tilburg, amid the hum of rotary dryers processing ale residues, the foreman detailed how prior vents allowed scents to drift, but our RTO locked them in, oxidizing completely and recycling heat to the inlet. This closed loop mirrored the efficient water cycles of Dutch polders, turning output into input seamlessly.

The energy angle shines in fuel-scarce times. In North Brabant’s cooperative breweries, our systems redirect oxidation warmth back to evaporators, trimming gas use amid national efficiency drives. Staff in Nijmegen have highlighted how this not only drops costs but stabilizes drying temps, yielding consistent grain moisture for better feed value.

Our presence across provinces like Gelderland ensures timely adaptations, from initial mappings to scaling for seasonal peaks. This grounded support builds lasting ties, especially when navigating the Netherlands’ integrated water and air policies, making our RTO a core element in your sustainable brewing chain.

Technical Specifications: 32 Key Parameters for Brewery DDGS and Beer Spent Grain Drying Exhaust RTO

| Parameter | Value/Range | Description |

|---|---|---|

| VOC Destruction Efficiency (DRE) | 97-99.5% | Breaks down ethanol and aldehydes from grain vapors. |

| Thermal Energy Recovery (TER) | 94-97% | Recaptures heat for dryer preheating in brewing cycles. |

| Airflow Capacity | 20,000-180,000 Nm³/h | Matches small craft to large industrial dryers. |

| Operating Temperature | 800-1000°C | Adjusted for moist, organic-rich exhausts. |

| Residence Time | 0.7-2.2 seconds | Maintains complete oxidation in humid flows. |

| Pressure Drop | 80-350 Pa | Low to support dryer fans. |

| Inlet VOC Concentration Range | 0.5-9 g/Nm³ | Handles variability from grain moisture levels. |

| NOx Emissions | <190 mg/Nm³ | Staged burners for compliance. |

| Particulate Removal | 90-97% | Captures grain dust pre-oxidation. |

| Turndown Ratio | 6:1 to 12:1 | Adapts to batch drying schedules. |

| Valve Cycle Time | 70-160 seconds | Balances efficiency in steamy conditions. |

| Leakage Rate | <0.09% per bed | Seals against odor escape. |

| Ceramic Media Heat Capacity | 0.85-1.25 kJ/kg·K | Robust for moisture tolerance. |

| Corrosion-Resistant Materials | 310 SS coatings | Resists acidic fermentation byproducts. |

| Explosion Protection | Integrated vents | Safety for alcohol vapors. |

| Control System | PLC/SCADA | Monitors for food-grade compliance. |

| Fotspor | 15-50 m² | Fits brewery layouts. |

| Maintenance Frequency | Every 4-8 months | Modular for quick brewery access. |

| Power Consumption | 0.45-1.7 kWh/Nm³ | Efficient for continuous runs. |

| Noise Level | <84 dB(A) | Quiet for worker areas. |

| Startup Time | 28-55 minutes | Fast for shift alignments. |

| Purge Cycle | 5-11 minutes | Clears moisture on stops. |

| Remote Monitoring | Cloud-based | For regulatory tracking. |

| Lifespan | 17-26 years | Durable in humid settings. |

| Certifications | CE, IED, HACCP | Meets EU food safety. |

| Heat Exchanger Efficiency | 87-94% | Secondary for process aid. |

| Bed Options | 4-9 beds | Custom for volume. |

| Cost Savings | 24-46% energy | Via recovery in operations. |

| Humidity Tolerance | Up to 85% RH | For wet grain exhausts. |

| Odor Reduction | 95-99% | Eliminates fermentation smells. |

| Dust Load Handling | High with cyclones | For grain particulates. |

| Automation Level | Full PLC | For unmanned shifts. |

These specs evolved from trials in Enschede’s breweries, where grain dust tested filters, prompting reinforced pre-stages in our models.

Compatibility with Leading Brands in the Netherlands and Beyond

| Brand | Compatibility Level | Key Features Compared | EVER-POWER Advantage |

|---|---|---|---|

| Dürr™ | High | Valve durability, TER emphasis | Comparable strength, cost-effective; Note: All manufacturer names and part numbers are for reference purposes only. EVER-POWER is an independent manufacturer. |

| Anguil™ | High | Custom for moist organics | Similar capability, faster Dutch service; Note: All manufacturer names and part numbers are for reference purposes only. EVER-POWER is an independent manufacturer. |

| Tecam Group | Medium-High | Recovery systems | Better brewery integration; Note: All manufacturer names and part numbers are for reference purposes only. EVER-POWER is an independent manufacturer. |

| Ship & Shore Environmental | Medium | Compact drying designs | Enhanced scale for volumes; Note: All manufacturer names and part numbers are for reference purposes only. EVER-POWER is an independent manufacturer. |

| John Zink Hamworthy Combustion | High | Burner efficiency | Matching low emissions, simpler care; Note: All manufacturer names and part numbers are for reference purposes only. EVER-POWER is an independent manufacturer. |

Our RTOs link smoothly with these brands’ dryers, facilitating updates in hybrid setups. This aids transits to Belgium and Germany, where akin brands prevail.

Environmental Regulations and Policies: Local, Regional, and Global Perspectives

Dutch brewing drying follows the Activities Decree, capping VOC at 30 mg/Nm³, with provinces like Utrecht requiring odor assessments for rural sites. Belgium’s VLAREM and Germany’s TA Luft demand BAT, favoring RTO for 98% reduction in organics.

Globally, US EPA MACT for food, China GB 16297-1996, Germany (as above), France IED, India FSSAI with CPCB, Canada CFIA guidelines, Japan Food Sanitation Law, South Korea MFDS Clean Air, Brazil ANVISA CONAMA 430, Turkey GTHB Air Quality, Russia Rospotrebnadzor SanPiN, Australia FSANZ NEPM, Mexico SALUD NOM-085, Spain MAGRAMA IED regional, Italy MIPAAF Decree 152, UK FSA EPR, Saudi SFDA PME, Indonesia BPOM PERMEN LH 5/2019, Poland GIS IED national, South Africa DAFF AQA, Argentina SENASA Resolution 177, UAE ESMA Federal 24, Vietnam MARD Law 2020, Thailand FDA Ministry Notification, Malaysia MOH EQA, Egypt MOHP Law 4, Philippines FDA RA 8749, Sweden Livsmedelsverket Environmental Code, Norway Mattilsynet Pollution Act, Finland Ruokavirasto EPA all enforce RTO-level controls for brewery emissions.

In Apeldoorn’s grain processors, RTO met local food safety audits, paralleling in Flemish Belgium and Bavarian Germany.

For Rotterdam’s export breweries, we align with global HACCP, while in Gelderland’s craft spots, prevent scent drift per community rules.

Essential Components, Spare Parts, and Consumables for RTO Systems

Main elements: rotary valves for direction, burners for start, saddle ceramics for storage. Spares: seals, probes, pilots. Consumables: dust filters, greases for drives. Transmission: gears, belts in alloy. In brewing, suggest steam-resistant ducts to handle moisture.

For grain-laden exhaust, cyclone pre-separators extend utility in Dutch plants.

Unique Characteristics of RTO in Brewery DDGS and Beer Spent Grain Drying Exhaust Scenarios

Grain drying vapors carry high moisture and dust, unlike dry malt kilns. Dutch wet climates amplify condensation, so insulated paths are vital. Fermentation residues add acids, needing robust chambers. Compared to mashing, drying has denser organics, requiring longer residences. Winters in Friesland cool inlets, our heaters counter. Unlike distillation, drying flows are steadier but dustier, where filters shine.

Personal Experiences and Real-World Case Studies

At a dryer in Zwolle for pilsner grains, the RTO tamed the steamy outflows, letting the crew extend runs without clogs. The lead shared how it quieted the stack, easing ties with nearby farms in this rural pocket.

In Leiden’s lager facility, recovered heat dried additional batches, boosting output without extra boilers. Operators in Limburg noted consistent feed quality post-upgrade.

Watch this footage of an EVER-POWER RTO at a Dutch brewery dryer, detailing vapor handling and energy return during a cycle.

From a setup in Delft, adjusted cyclones caught fine husks, a refinement from coastal humid trials.

Enhancing Your Operations with Additional Insights

Tie RTO to sensors for grain moisture prediction, optimizing dries in variable harvests. For green brews, bio-fuel adaptations cut carbons. In delta zones like Zeeland, elevate against tides. Recent works on enzyme pre-treats reduce vapors, pairing with RTO for lesser loads.

Try solar aids for daytime heats in sunny South Holland, easing grid loads. From EU bioeconomy grants, AI maps emission peaks for proactive vents.

Latest News on RTO in the Brewery DDGS and Beer Spent Grain Drying Industry in the Netherlands and Europe

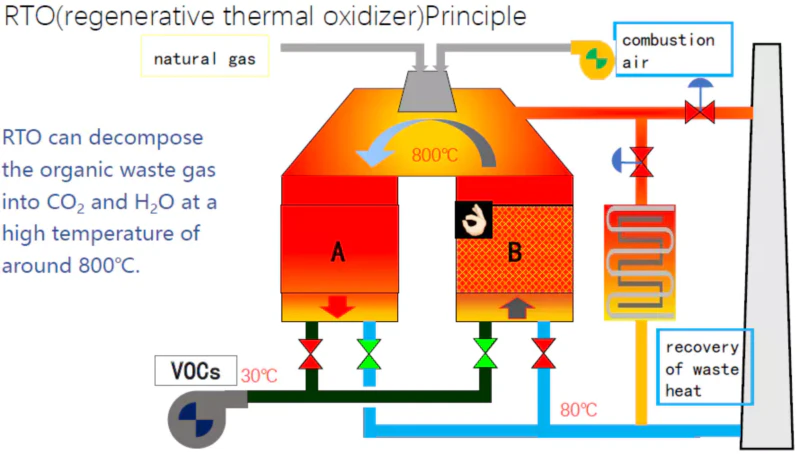

- RTO for Brewery DDGS & Spent Grain Drying achieves 800°C oxidation for CO2/H2O conversion (December 9, 2025).

- Beer goes green with EU’s 3.4 million tonnes spent grain yearly, highlighting RTO in by-product management (September 24, 2025).

- US ethanol/DDGS exports record in August 2025, implying RTO needs in global drying (November 19, 2025).

- Brewer’s spent grain innovations in food via RTO-cleaned processes (recent PMC article).

- Europe Brewery Spent Grain Market at USD 509.25 Mn in 2024, growing 2.88% CAGR with RTO aid (recent report).

- European brewers on US tariffs, indirectly boosting RTO for efficient drying (April 10, 2025).

- Regenerative Thermal Oxidizer market to $602.2M in 2025 (October 18, 2025).

- RTO market segmentation to 2035 (January 27, 2025).

- RTO market at USD 10.25B in 2024 to 16.37B (June 12, 2025).

- The New Brewer on climate, noting RTO in brewing (January/February 2025).

Contact our team in Rotterdam to obtain a customized RTO blueprint to drive your project’s sustainability.