Katalytisk oksidasjonsmiddel

Low-temperature and high-efficiency carbon monoxide purification solution

CO Technology Overview

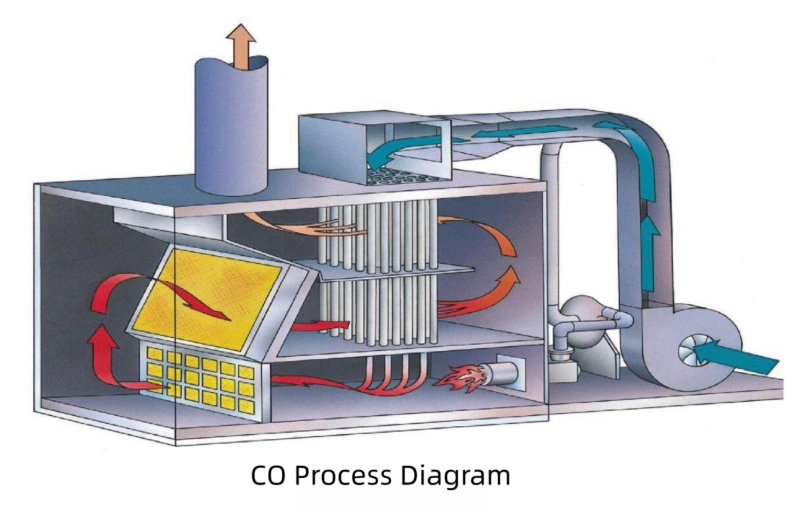

A catalytic oxidizer (CO) is an advanced waste gas treatment device that uses a catalyst to oxidize carbon monoxide (CO) and other volatile organic compounds (VOCs) into carbon dioxide (CO₂) and water (H₂O) at relatively low temperatures (300-500°C). Compared with thermal oxidation, catalytic oxidation technology significantly reduces energy consumption and operating costs, and is particularly suitable for treating low-to-medium concentration, high-volume CO waste gas.

Working Principle

Catalytic oxidation achieves efficient CO purification through four steps:

- Exhaust gas preheating: Exhaust gas is preheated to the catalyst ignition temperature via a heat exchanger.

- Catalytic oxidation: An oxidation reaction occurs on the catalyst surface: 2CO + O₂ → 2CO₂

- Heat recovery: The heat of reaction is recovered via a heat exchanger to preheat the inlet gas.

- Purified emission: The compliant gas is emitted through a chimney after catalytic oxidation.

Why choose Catalytic Oxidizer?

|

Advantage Feature < |

Catalytic Oxidizer (CO) < |

Traditional Thermal Oxidizer (TO) < |

RTO

< |

|---|---|---|---|

| Operating Temperature | 300-500°C | 760-1200°C | 760-950°C |

| Energy Consumption | Reduced by 40-70% | High | Extremely low (at high concentrations) |

| Startup Time | 15-30 minutes | 1-2 hours | 45-90 minutes |

| Space Requirement | Compact, saves 30-50% | Relatively large | Moderate |

| Suitable Concentration | 100-5,000 ppm | High concentration | Wide range |

Our catalytic oxidation system ensures compliance with:

USA

- EPA Method 25A for CO

- EPA Method 25 for VOCs

EU

- EN 13649 sampling standard

- Compliant with the IED Directive

China

- GB 16297-1996

- DB11/501-2017 (Beijing local standard)

Typical Application Scenarios

Automobile Manufacturing and Painting

- Drying oven exhaust gas: CO concentration 200-800ppm, containing VOCs

- Welding fumes: Local exhaust treatment

- Challenges: Large air volume, fluctuating concentration, contains siloxanes

- Solution: Front-end adsorption concentration + catalytic oxidation system

Printing and Packaging

- Flexographic and gravure printing exhaust gas: alcohols, esters, solvents, containing CO

- Complex process exhaust gas: a mixture of multiple pollutants

- Solution: specialized anti-silicon catalyst, periodic regeneration process

Electronics and Semiconductor Manufacturing

- CVD process exhaust gas: Contains silanes and CO, easily forming silica.

- Solution: Two-stage pretreatment + high-temperature catalyst.

- Special design: Prevents dust ingress, protecting the catalyst.

Chemicals and Pharmaceuticals

- Reactor exhaust: intermittent emission with large concentration variations

- Solvent recovery tail gas: low concentration of CO and VOCs

- Solution: buffer system + adaptive control catalytic oxidation

Food processing

- Drying and baking exhaust gas: contains aldehydes and CO, high humidity

- Challenge: Contains grease and dust, easily contaminating the catalyst

- Solution: High-efficiency filtration + waterproof catalyst coating

Case Studies

🏭 Large Automobile Painting Plant Drying Oven Exhaust Treatment

📋 Project Background

Exhaust gas from painting line drying oven in an automobile manufacturing plant

Air volume: 80,000 Nm³/h

🔬 Exhaust Gas Characteristics

- CO: 300-600 ppm

- VOCs: 200-400 mg/Nm³ (mainly n-hexane, xylene)

- Temperature: 120-150°C (partially preheated)

- Contains trace amounts of siloxanes (from sealants)

🔧 Solution

Pretreatment System:

- Electrostatic precipitator to remove overspray paint mist

- Activated carbon adsorption for siloxanes

- Bag filter for final filtration

Catalytic Oxidation System:

- Plate heat exchanger with 75% heat recovery efficiency

- Precious metal catalyst with 240°C ignition temperature

- Four-zone temperature control for optimized energy consumption

Intelligent Control System:

- Automatically adjusts burner power based on concentration

- Catalyst temperature protection logic

- Real-time energy efficiency monitoring and optimization

Operational Results

- CO removal efficiency: 99.2%

- VOCs removal efficiency: 98.5%

- Energy consumption: 45% more efficient than RTO方案

- Operating temperature:

- Inlet preheated to 320°C

- Reaction temperature 380°C

- Fuel consumption: 25 Nm³/h natural gas (average)

- Investment payback period: 1.8 years

- Annual operating cost savings: $120,000

FAQ

Frequently Asked Questions

Catalytic Oxidation Systems & Emission Control

Catalytic Oxidizers (CO) achieve pollutant oxidation at 300-500°C with the help of catalysts, while RTOs perform thermal oxidation at 760-950°C using heat storage ceramics. The core differences are:

- Energy consumption: CO saves 40-70% in fuel consumption

- Startup time: CO requires only 15-30 minutes, RTO needs 45-90 minutes

- Concentration suitability: CO optimally handles 100-5,000ppm, RTO suits a wider range

- Investment cost: CO systems typically cost 20-40% less than RTOs

Application recommendation: Choose CO for low-medium concentration, intermittent emissions; choose RTO for high concentration, continuous emissions.

We employ a three-level protection strategy:

- Front-end activated carbon adsorption (targeting siloxanes)

- Electrostatic precipitation + bag filtration (removing dust)

- Siloxane online monitoring system

- Silicone-resistant formulated catalyst (with silicon scavenger added)

- Layered design: protective layer + reaction layer

- Regular high-temperature regeneration procedure (650°C to remove deposits)

- Bypass system (automatic switching during high silicon levels)

- Catalyst activity monitoring system

- Predictive maintenance algorithm

Practical case: A Dutch automotive painting plant using this solution extended catalyst life from 6 months to 3 years.

Special design is required to prevent acid corrosion and dioxin formation:

- Material upgrade: Reactor uses Inconel 625 or Hastelloy C-276

- Temperature control: Maintain above 850°C to ensure complete decomposition

- Post-treatment: Quench tower + caustic washing tower (neutralizing HCl/HF)

- Monitoring requirements: Continuous monitoring of HCl, HF and dioxin precursors

- Compliance guarantee: Meets Dutch BAT conclusion documents for halogen-containing exhaust gases

Our system incorporates four compliance modules:

- CO analyzer (EN 15267-3 certified)

- VOC online monitoring (compliant with EN 13649)

- Data recording meets NTA 8075 standards

- Automatic generation of quarterly emission reports

- Automatic alarm and event recording for exceedances

- Electronic reports directly connected to environmental department systems

- Annual third-party performance verification

- BAT compliance statement documents

- Complete operation and maintenance records

- Regulatory dynamic tracking service

- Regular software updates

- Annual compliance audit

Required certifications include:

- ATEX explosion-proof certification (Zone 1 & Zone 2)

- PGS 28 safety distance compliance certificate

- CE marking (Machinery Directive, Pressure Equipment Directive)

- SIL 2 Safety Integrity Level certification

- NEN-EN-ISO 13702 emergency system certification

Additional service: We provide full certification application assistance, reducing certification time by an average of 60%.

Typical economic analysis (30,000 Nm³/h system):

- Normal operating conditions: 3-5 years (24,000-40,000 hours)

- Severe operating conditions: 2-3 years (with regeneration maintenance)

- New catalyst cost: €45,000-€75,000 (approximately 15-25% of system)

- Regeneration service: €15,000-€25,000 (restores 90%+ activity)

- Spent catalyst recycling: €5,000-€10,000 return value (precious metal recovery)

- Activity monitoring package (3 months advance warning)

- Regeneration service contract (extends service life by 50%)

- Trade-in program (30% discount on new catalyst)

We provide intelligent buffering solutions:

At low concentrations (<500ppm):

- Reduce preheating temperature to 280-320°C

- Decrease fan frequency

- Enter energy-saving standby mode

At high concentrations (>2,000ppm):

- Automatically activate cold air blending

- Maximize heat recovery

- Start excess heat utilization system

- Exhaust gas buffer tank (15-30 minutes buffering capacity)

- Adsorption concentration rotor (concentrates low concentrations 10-20 times)

- Multi-reactor parallel design (adapts to production fluctuations)

Typical energy recovery solutions:

- Hot air recovery (simplest):

- Temperature: 150-250°C

- Applications: process preheating, space heating

- Efficiency: 60-75%

- Hot oil system (medium temperature):

- Temperature: 200-300°C

- Applications: process heating, steam generation

- Efficiency: 70-80%

- Steam generation (high temperature):

- Pressure: 4-10 bar

- Applications: process steam, power generation

- Efficiency: 75-85%

- Organic Rankine Cycle power generation:

- Power generation efficiency: 8-15%

- Investment payback period: 3-5 years

- Suitable for: >10,000 Nm³/h large systems

Economic benefit example:

Processing capacity: 50,000 Nm³/h

Exhaust gas temperature: 400°C reduced to 150°C

Recovered heat: 4.2 MW

Annual benefit: €150,000-€250,000 (subject to natural gas price fluctuations)

Based on European automotive plant experience, recommended solutions:

- VOC: 200-800 mg/Nm³ (contains benzene series, esters)

- CO: 100-400 ppm

- Siloxanes: trace amounts (from sealants)

- Operation mode: intermittent, following production rhythm

- Direct catalytic oxidation (suitable for small-medium scale):

- Investment: €300,000-€500,000

- Energy consumption: 25-40 Nm³/h natural gas

- Features: simple and reliable, easy maintenance

- Zeolite rotor + catalytic oxidation (suitable for large air volume):

- Investment: €800,000-€1,200,000

- Energy consumption: reduced by 60-70%

- Features: ultra-high concentration processing capacity

- Hybrid system (RCO + waste heat utilization):

- Investment: €1,000,000+

- Features: energy self-sufficient, zero fuel consumption

Success case: A Mercedes-Benz painting plant in the Netherlands adopted solution 2, achieving:

65% energy reduction

VOC removal efficiency >99%

Annual savings of €180,000

Dual certification by German VDA and Dutch environmental authorities