WAM Gas Treatment

Within the Netherlands and the EU, methane emissions are strictly controlled as a major short-term climate pollutant (SLCP). RTO (thermal rotary oxidation) technology provides an efficient treatment solution for WAM gas, converting it into carbon dioxide and water at high temperatures, meeting EU emission standards, particularly the emission reduction targets outlined in the European Green Deal.

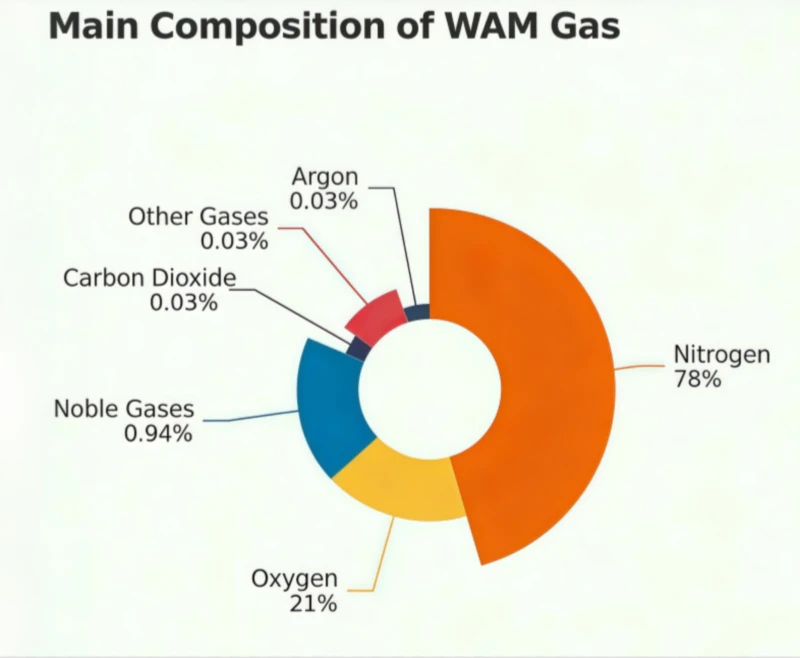

WAM Gas Overview

WAM (Waste Air Methane) gas primarily originates from methane emissions in industrial waste gases and is widely found in landfills, mine ventilation gases, and waste incineration. Methane is a greenhouse gas with a global warming potential 25 times that of carbon dioxide; therefore, effectively controlling its emissions is crucial for addressing climate change and improving air quality.

RTO Technology Overview

RTO (Regenerative Thermal Oxidation) is a highly efficient waste gas treatment technology widely used in the treatment of various industrial waste gases. RTO technology utilizes the principle of high-temperature oxidation to convert harmful components in waste gases (including methane, VOCs, etc.) into harmless gases, achieving purification. Simultaneously, RTO technology boasts an extremely high heat recovery rate, effectively reducing energy consumption, complying with EU environmental regulations, and helping companies meet Dutch environmental standards.

RTO Workflow

Core Advantages of RTO for WAM Gas Treatment

Efficient Methane Removal

Through high-temperature oxidation, Methane (CH₄) is completely converted into CO₂ and water vapor, achieving a removal rate of over 99%.

Thermal Recovery & Cost Reduction

The system utilizes waste heat to preheat incoming gas, reducing overall energy consumption by 20% - 30% and lowering operational costs.

Regulatory Alignment

Ensures that emissions fully comply with the EU Emissions Trading System (EU ETS) and Dutch environmental standards, avoiding legal risks.

Secure & Stable Operation

Features automated monitoring of temperature and gas concentration to prevent fire or explosion risks, ensuring high operational stability.

Expertise & Qualifications

Leveraging our collaboration with the National Engineering Laboratory for Volatile Organic Pollutant Control Materials and Technologies (Shaanxi Branch), jointly established with the University of Science and Technology of China and Xi’an Jiaotong University, we focus on research in thermal energy storage combustion technology and molecular sieve adsorption technology. As part of our global innovation efforts, we aim to create a shared technology research and development platform to promote cross-industry collaboration and progress, and to cooperate with leading institutions in the Netherlands and other EU countries.

The company has registered a total of 48 patents, including 13 invention patents. Specifically, we have obtained 2 invention patents, 24 utility model patents, 5 design patents, and 4 software copyrights. These innovative achievements not only comply with EU environmental standards but also contribute to the development of sustainable technologies and the realization of the European Green Deal and the principles of the circular economy.

Application Scenarios of RTO for Treating WAM Gas

Landfill

Methane emissions from landfills are released through ventilation systems. Real-time oxidation (RTO) technology can efficiently convert this methane into carbon dioxide and water, reducing climate impact and meeting Dutch and EU emission standards.

Coal and Natural Gas Mining

Methane emissions from coal and natural gas extraction are also a significant source of WAM (meta-alcoholic gases). Reduction of methane emissions (RTO) in mine ventilation gases can effectively reduce methane levels, thereby decreasing greenhouse gas emissions and improving environmental safety.

Waste Incineration

During waste incineration, exhaust gases often contain large amounts of methane and other harmful substances. Regenerative Thermal Oxidation (RTO) technology can efficiently treat these exhaust gases, ensuring that incineration plant emissions comply with environmental regulations and reducing greenhouse gas emissions.

Industrial Waste Gas Treatment

In industries such as chemical processing, oil refining, and pharmaceuticals, many processes release greenhouse gases such as methane. Through RTO (Regenerative Thermal Oxidizer) technology, these waste gases can be effectively treated, reducing industrial methane emissions and meeting EU waste gas treatment standards.

User Reviews

“We have always faced the challenge of waste gas treatment, especially when dealing with VOCs and methane. After introducing RTO technology, the efficiency of waste gas treatment has been greatly improved, with PM2.5 and methane removal rates reaching over 99%, fully complying with Dutch environmental regulations. The heat recovery system not only helps us save energy but also significantly reduces emissions. We are very grateful for the team’s professional support; the stable operation of the RTO equipment has saved us production costs while also contributing to the company’s environmental goals.”

Anna Smit

“Our landfill produces a large amount of methane gas every year, which has a huge impact on the environment and climate. Since the introduction of the RTO system, the methane gas has been effectively converted into carbon dioxide and water, and the emissions fully comply with the EU Green Deal and Dutch air quality standards. The efficient operation of the system has not only helped us reduce emissions, but also reduced energy consumption through heat recovery. RTO technology is indeed an ideal choice for solving the methane control problem.”

Mark van der Horst

“Our coal mine’s ventilation exhaust contains a large amount of methane, and the previous treatment methods were inefficient and costly. After choosing RTO technology, the methane in the exhaust is treated with high efficiency, with a removal rate of over 99%, and it meets EU emission regulations. The RTO system not only effectively reduces greenhouse gas emissions, but also helps us save energy and reduce production costs. We are very satisfied with the environmental and economic benefits brought by this technology.”

Pieter Jansen