In the Netherlands, from the food processing hubs in Noord-Brabant to the production facilities in Groningen, the pet food industry is undergoing a “humanization” revolution. To achieve peak palatability, manufacturers utilize complex mixtures of hydrolyzed proteins, animal fats, and flavor enhancers during the coating stage.

However, this process generates intense odorous pollution and persistent oil mists. Under the strict enforcement of the Dutch Activiteitenbesluit milieubeheer (Activities Decree), how can producers ensure complete odor elimination while maintaining high energy efficiency? The Regenerative Thermal Oxidizer (RTO) provides the definitive answer.

The Core Challenge: Why is Pet Food Exhaust Difficult to Treat?

1. Why are traditional scrubbers often ineffective?

Pet food exhaust is not a single-component gas. It contains mercaptans, sulfides, volatile fatty acids, and significant amounts of viscous oil mists. Simple chemical scrubbing only removes hydrophilic odors; it is largely ineffective against hydrophobic organic compounds and residual oils, often resulting in secondary wastewater issues.

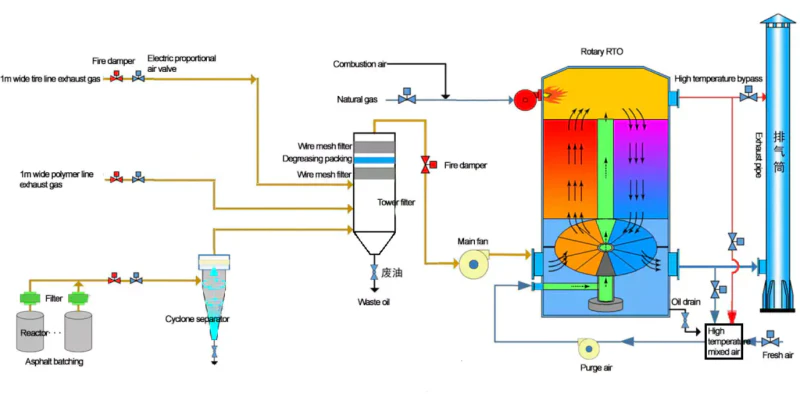

2. What is RTO technology?

RTO (Regenerative Thermal Oxidizer) is a technology that utilizes high-temperature oxidation (typically above 815°C) to completely decompose odor molecules into $CO_2$ and $H_2O$. Its Thermal Energy Recovery (TER) rate of 95%-97% drastically reduces operational costs.

3. Is RTO suitable for the coating and flavoring stage?

Absolutely. RTO is recognized as the most effective technology for achieving “zero-odor” emissions, particularly for high-concentration, high-humidity exhaust generated during vacuum spraying or continuous drum coating.

RTO Core Technical Parameters

RTOs designed for pet food applications must feature robust oil-mist resistance and thermal stability. Below are the critical selection parameters:

Key Technical Parameters Table

| Technical Metric | Parameter Range | Impact on Pet Food Operations | Reference Standard |

|---|---|---|---|

| Operating Temp | 815 – 950°C | Critical for the complete cracking of mercaptans | EPA 452/B-02-001 |

| Destruction Efficiency | ≥ 99% | The only guarantee for zero neighborhood complaints | EU IED Directive |

| Thermal Recovery (TER) | 95% – 97% | Transforms abatement equipment into an energy center | Industrial Energy Standards |

| Residence Time | 0.75 – 1.0 Sec | Ensures full oxidation of complex lipid molecules | Kinetic Modeling |

| Pre-filtration Precision | < 5μm | Prevents oil clogging and ceramic media fouling | Filtration Standards |

| Online Bake-out | Standard Feature | Periodically cleans fats from ceramic surfaces | Maintenance Protocols |

Parameter Impact Analysis:

- Thermal Energy Recovery (TER): Pet food plants are typically high-energy consumers. A TER of 95%+ means the residual heat from the RTO can be redirected through heat exchangers to produce hot water for raw material thawing or flavoring liquid heating, creating a closed-loop energy system.

- Destruction Removal Efficiency (DRE): Due to the presence of complex fatty acids, even a slightly shorter residence time can result in a “burnt” odor. A precise design (≥0.75s) is the key to ensuring the stack is truly odorless.

RTO Application Characteristics: Pros and Cons

Scenario Analysis: The “Sticky & Smelly” Coating Process

- Characteristics: High fat content, high humidity, and high olfactory recognition.

- Advantages:

- Complete Odor Removal: Thermal oxidation is the only technology capable of reducing odors below the perception threshold.

- Auto-thermal Operation: The high caloric value of fat vapors often allows the RTO to run without auxiliary fuel once the process is steady.

- Limitations:

- Maintenance Requirements: Without effective pre-treatment, fats can carbonize on the ceramic media.

- Initial Investment: Higher CAPEX compared to carbon filters, but offers a superior Total Cost of Ownership (TCO) within 3-5 years.

Critical Components & Ecosystem Support

For the pet food industry, we recommend the following specialized components:

- Modular Fiber-Bed Filters (Pre-treatment): The RTO’s “body armor.” These must be washable with high capture rates specifically for viscous oil mists.

- Large-Aperture Honeycomb Ceramics: Prevents clogging by particulate matter and improves airflow distribution.

- Online Bake-out System: An automated program that raises the furnace temperature to gasify and burn off fat deposits, enabling self-cleaning.

- Secondary Heat Recovery (Air-to-Water): Redirects free thermal energy back to the production line for significant cost savings.

Mainstream RTO Brand Comparison (Pet Food Perspective)

| Brand | Core Strength | Energy Recovery | Decision Logic |

|---|---|---|---|

| Dürr (Ecopure) | Top-tier stability and ultra-low emissions for large groups. | 97% | Best for large-scale plants in highly regulated areas like Rotterdam. |

| Ever-Power | Specialized Niche Focus; features “oil-resistant” RTO designs for pet food. | 96% | Preferred for cost-performance and integrated oil-mist/heat recovery. |

| Anguil | Deep experience in treating mixed odors and additive exhaust. | 95% | Suitable for diversified lines with highly complex gas compositions. |

Global and Local Market Context (Netherlands Local SEO)

In the Netherlands, managing industrial odor complaints is a primary environmental responsibility.

- Dutch Market:

- Regulations: The Dutch Activiteitenbesluit sets clear limits on odor units.

- Incentives: Investing in high-efficiency RTOs qualifies for the EIA (Energie-investeringsaftrek) energy investment tax credit.

- Global Trends:

- USA: Regulated by EPA NESHAP with a focus on public health impacts of odor.

- Middle East: As pet ownership grows, facilities in cities like Jeddah are facing increased pressure for odor abatement.

Success Case Study

Field Experience: Eliminating the “Lingering Chicken Fat” Smell

In a recent project in Noord-Brabant, a well-known pet food producer faced frequent complaints from the surrounding community due to their flavoring process.

- Pain Point: The existing chemical scrubber was failing, and the workshop was coated in grease.

- Solution: We implemented an Ever-Power Integrated RTO System with three-stage mechanical de-misting.

- Result: Stack odor became undetectable to the human nose, complaints dropped to zero, and the RTO provided 60°C hot water for the production line.

Future Trends & Sustainability

- Hydrogen-Ready RTOs: To meet the European Green Deal, future burners will support hydrogen blending for zero-carbon treatment.

- Smart Odor Tracing: Utilizing AI and sensor arrays, RTOs can automatically adjust intensity based on the specific recipe being run.

- Circular Economy: Exploring the potential to transform captured fats into biomass energy.

Conclusion: In the pet food sector, an RTO is no longer just an environmental expense; it is a core asset that protects brand reputation, ensures compliance, and drives energy recovery.

SEO Tags:

- Nederlands: Geurbestrijding diervoeding, RTO naverbranding, VOS-reductie petfood.

- English: Pet food odor control, RTO for palatant coating, VOC abatement.