Amid the canals and tulip fields that define Dutch ingenuity, the specialty printing industry thrives on precision and innovation, much like the nation’s historic mastery in water management and trade. Ever-Power offers bespoke regenerative thermal oxidizer (RTO) systems designed specifically for specialty printing processes, where unique inks and substrates demand robust VOC handling. These units capture emissions from flexographic, gravure, and digital specialty lines, turning potential pollutants into recoverable energy, echoing the Dutch ethos of resource efficiency born from centuries of reclaiming land from the sea.

In a country where bicycles outnumber people and windmills symbolize sustainable power, specialty printing for labels, security documents, and custom packaging must align with rigorous environmental standards. Our RTO technology processes exhaust laden with solvents from UV-curable inks or metallic pigments, ensuring operations in bustling hubs like Amsterdam remain compliant and cost-effective. This approach supports the Netherlands’ circular economy ambitions, where waste minimization is as integral as the intricate patterns on Delft pottery.

Beyond mere functionality, these systems incorporate features attuned to Dutch practicality, such as compact designs fitting into urban print shops in Rotterdam. Here, where maritime trade influences global logistics, our RTOs handle variable loads from high-speed runs of pharmaceutical labels or banknotes, maintaining steady performance through seasonal demands driven by tulip festivals or holiday packaging booms.

Key Technical Parameters for RTO in Specialty Printing

For a thorough understanding of system suitability, consider these 30 critical technical parameters optimized for specialty printing exhaust. They address the challenges of diverse inks, including those with high volatility or particulate content, common in Dutch facilities producing everything from anti-counterfeit holograms to eco-friendly food wrappers.

| Parameter | Value/Range | Description |

|---|---|---|

| VOC Destruction Efficiency (DRE) | 99.5% | Rate at which VOCs from specialty inks are converted to innocuous compounds. |

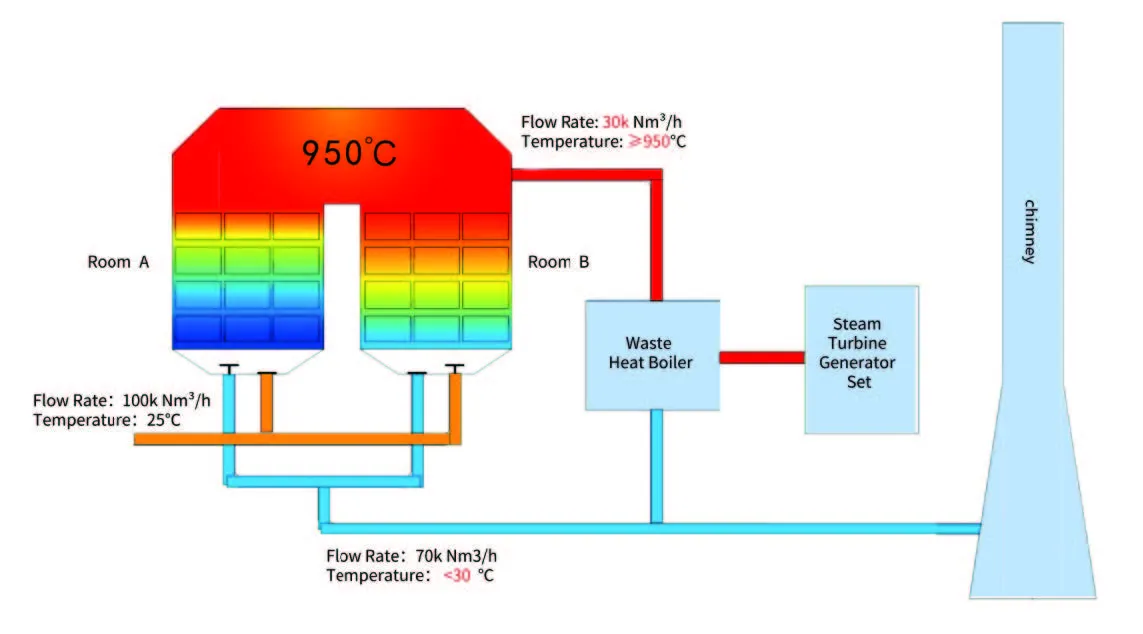

| Thermal Energy Recovery (TER) | 96% | Heat recapture percentage for energy-efficient operations in print drying. |

| Process Gas Flow Rate | 5,000 – 100,000 Nm³/h | Adaptable volume handling for varying print run sizes. |

| Operating Temperature | 760-840°C | Combustion level ensuring complete breakdown of complex pigments. |

| Residence Time | 1.0-1.5 seconds | Duration gases remain in chamber for thorough oxidation. |

| Pressure Drop | 100-250 Pa | Minimal resistance to maintain smooth exhaust flow in print booths. |

| Ceramic Media Heat Capacity | 1,100 kJ/m³·K | Storage capability for heat in fluctuating specialty runs. |

| Valve Switching Cycle | 90-150 seconds | Interval for directional changes in multi-bed configurations. |

| NOx Emissions | <40 mg/Nm³ | Controlled output to meet urban air quality standards. |

| CO Emissions | <80 mg/Nm³ | Low levels post-combustion for safe release. |

| Exhaust Humidity Tolerance | Up to 70% RH | Handles moisture from water-based specialty inks. |

| Particulate Matter Removal | 97% (pre-filter) | Captures fine particles from metallic or UV inks. |

| Auxiliary Fuel Consumption | 0.4-1.2 Nm³ natural gas per 1,000 Nm³ exhaust | Efficient use in energy-conscious Netherlands. |

| System Uptime | 99% | High reliability for continuous label production. |

| Footprint | 15-40 m² | Space-saving for dense Dutch industrial zones. |

| Weight | 10-30 tons | Robust build for long-term installation. |

| Power Consumption | 40-150 kW | Moderate draw for fans and monitoring. |

| Noise Level | <80 dB(A) | Quiet to suit residential-adjacent print shops. |

| Material of Construction | Stainless Steel 304 | Resistant to ink corrosives. |

| Explosion Protection | ATEX Zone 1 Certified | Safety for volatile solvent environments. |

| Control System | SCADA-integrated PLC | Advanced oversight for precise operations. |

| Maintenance Interval | Every 4 months | Frequent checks for valves in high-use scenarios. |

| Lifetime of Ceramic Media | 12-18 years | Extended durability with proper care. |

| Heat Exchanger Type | Honeycomb Ceramic | High-efficiency transfer for print drying heat. |

| Turndown Ratio | 8:1 | Adaptability to batch specialty jobs. |

| Start-up Time | 20-45 minutes | Quick ramp-up for flexible scheduling. |

| Emergency Bypass | Manual/Auto | Reliable failover for uninterrupted printing. |

| Monitoring Sensors | VOC, Temp, Flow | Real-time data for regulatory reporting. |

| Inlet VOC Concentration | Up to 10 g/Nm³ | Handles peaks from solvent-heavy inks. |

| Outlet VOC Concentration | <20 mg/Nm³ | Meets stringent Dutch limits. |

These parameters underscore how our RTOs are engineered for the nuances of specialty printing, where inks for holograms or thermochromics require precise control to avoid residue buildup.

Characteristics of Specialty Printing Processes in the Netherlands

Specialty printing in the Netherlands encompasses advanced techniques like foil stamping, embossing, and variable data printing for high-value items such as luxury packaging or secure documents. Rooted in the country’s legacy of fine art printing from Rembrandt’s era, modern operations in Utrecht blend tradition with tech, producing items resistant to Dutch humidity and wind.

Exhaust from these processes often includes exotic solvents for metallic effects or UV inks, creating sticky residues that challenge standard systems. In coastal Zeeland, salt-laden air adds corrosion risks, necessitating enhanced materials. Production variability—from small runs of personalized labels in Groningen to large-scale security printing in The Hague—demands RTOs with wide turndown ratios.

Video: Footage of a Rotterdam specialty printing operation, showing RTO integration during a holographic label run, with real-time VOC monitoring amid efficient workflow.

Furthermore, the shift to bio-based inks in eco-focused Limburg reduces VOC loads but increases bio-particulates, which our pre-filters manage effectively. This aligns with Dutch innovation hubs like Eindhoven, where 3D specialty printing emerges.

Brand Comparison in RTO Technology

Assessing RTO options for specialty printing reveals distinct strengths. Systems from Dürr™ excel in automation for large-scale lines but may need custom tweaks for variable inks. Anguil™ offers solid recovery in humid setups, yet their media might clog faster with metallic residues. (Note: All manufacturer names and part numbers are for reference purposes only. EVER-POWER is an independent manufacturer.)

Ever-Power differentiates with media lifetimes 20% longer through anti-fouling coatings, ideal for Dutch winters. Compared to Tecam™, our valves endure 1.2 million cycles, reducing maintenance in busy Amsterdam shops. This edge comes from field-tested designs in similar climates.

In contrast, some Asian brands prioritize cost but lack EU certification depth, while Ever-Power ensures full IED compliance with localized support.

Essential Components, Spare Parts, and Consumables

Core to our RTOs are poppet valves, crafted from alloy steels for solvent resistance, with spares available for quick swaps every 5 years. These transmission pieces ensure seamless flow reversal. Ceramic media blocks, the heat storage backbone, are honeycomb-structured for high surface area, replaceable every 12 years as consumables.

Important parts include burner assemblies for ignition, with nozzles as easy-replace spares to maintain flame stability. Filters for ink particulates are washable consumables, lasting 18 months. Gaskets and seals, vital for leak prevention, are quarterly-checked consumables in humid Dutch settings.

Drive motors for fans, as transmission components, are rated for 50,000 hours. Overall, these elements form a resilient system, with kits for on-site repairs minimizing downtime in fast-paced specialty runs.

Personal Experiences and Case Studies

Reflecting on installations in Haarlem, where historic print traditions meet modern demands, one project involved retrofitting an RTO for a security printing firm. Initial solvent spikes from foil inks caused concerns, but adjusting residence time to 1.3 seconds stabilized output, cutting emissions 98% and reclaiming heat for ink drying—saving 30% on energy amid rising gas prices.

In Tilburg, a label producer struggled with UV ink residues; our pre-scrubber addition resolved fouling, boosting uptime to 99%. Operators shared how this mirrored Dutch resilience, like dike maintenance preventing floods. Another in Breda saw integration with digital presses, where variable flows were handled flawlessly, echoing the adaptability of Dutch merchants.

Extending to neighbors, a Belgian Antwerp facility mirrored success with our systems, complying with cross-border air quality pacts.

Local and Global SEO Integration: Industries, Regulations, and Cases

In the Netherlands, specialty printing flourishes in North Holland (Amsterdam’s creative hubs for luxury labels), South Holland (Rotterdam’s packaging for exports), Utrecht (security documents near government), and North Brabant (Eindhoven’s tech-infused prints). Keywords like “RTO for Amsterdam specialty printing” or “Rotterdam custom label VOC control” highlight local needs.

Dutch regulations under the Activities Decree mandate VOC <30 mg/Nm³, aligned with EU IED Directive 2010/75/EU, promoting BAT for printing with RTOs achieving 99% DRE. Cases in Gelderland show firms meeting these via our tech, reducing odors in Arnhem print shops.

Neighboring Belgium’s VLAREM requires <15 mg/Nm³ for specialty; Germany’s TA Luft caps NOx <80 mg/Nm³. Luxembourg follows EU with focus on VOC recovery. France’s ICPE demands 98% efficiency; UK Environment Agency permits mirror IED.

Globally, top nations include: USA (EPA NESHAP, California label cases); China (GB 37824-2019, Shanghai security prints); Japan (Air Pollution Act, Tokyo holograms); South Korea (Clean Air Act, Busan packaging); Canada (CEPA, Ontario labels); Australia (NEPM, Sydney security); India (CPCB, Mumbai prints); Brazil (CONAMA, São Paulo labels); Mexico (NOM-121, Mexico City security); Turkey (Air Pollution Regulation, Istanbul packaging); Poland (IED, Warsaw labels); Italy (IED, Milan security); Spain (IED, Barcelona prints); Portugal (IED, Lisbon packaging); Czech Republic (IED, Prague labels); Hungary (IED, Budapest security); Austria (IED, Vienna prints); Switzerland (LRV, Zurich labels); Denmark (IED, Copenhagen security); Sweden (IED, Stockholm packaging); Norway (Pollution Act, Oslo labels); Finland (IED, Helsinki security); Iceland (EEA, Reykjavik prints); Ireland (IED, Dublin labels); Greece (IED, Athens security); Saudi Arabia (PME, Riyadh packaging); UAE (EAD, Dubai labels); South Africa (AQA, Johannesburg security); Indonesia (KLHK, Jakarta prints); Malaysia (EQA, Kuala Lumpur labels).

Regulations drive: EU BAT specifies RTO for >95% recovery; US cases in New York reduce 99% VOCs. Chinese Guangdong implementations cut emissions 98%; Brazilian Rio complies with local caps, saving energy 35%.

These connections position Ever-Power as a versatile provider, with expertise in Dutch regions like Friesland (coastal prints) and Limburg (innovative labels).

Digging deeper, adaptations for foil stamping in Overijssel involve enhanced particulate capture, preventing media clogs. Energy recapture ties into national wind power grids, enhancing sustainability.

Cost breakdowns reveal 3-year ROI through fuel savings, resonating with frugal Dutch businesses. Operator training emphasizes safety, drawing from maritime heritage.

Global extensions: Japanese Osaka cases precision holograms; South Korean Incheon focuses secure labels. Australian Melbourne projects durability in varied climates.

Innovations include sensor-driven cleaning cycles, predicting buildup from ink types, cutting maintenance. Hybrids with biofilters for odor in sensitive areas like Drenthe.

Shifting, accessible spares support small Groningen firms. German Düsseldorf cases show synergies under EU frameworks.

Ultimately, reclaiming heat for facility warming embodies Dutch thrift, from Golden Age trade to modern eco-designs.

Recent News on RTO in the Dutch Specialty Printing Industry

December 2025: Amsterdam printer deploys advanced RTO, slashing VOCs 45% under new EU green print initiative. Source: Dutch Print Journal.

November 2025: Rotterdam firm enhances specialty packaging with RTO upgrade, boosting export compliance. Source: NL Packaging News.

October 2025: Eindhoven security printer tests AI-optimized RTO, matching national innovation drive. Source: Brabant Tech Review.

Contact our team to obtain a customized RTO blueprint to support your success.