PM2.5 Gas Treatment

In the Netherlands, PM2.5 (fine particulate matter) is a major air pollutant that significantly impacts air quality and public health. PM2.5 particles with a diameter of 2.5 micrometers or less can penetrate deep into the lungs and even enter the bloodstream, posing long-term health risks. RTO (thermal rotary oxidation) technology is currently a highly efficient and environmentally friendly solution for treating PM2.5 emissions and is widely used in industrial waste gas treatment in the Netherlands, helping companies meet stringent environmental emission standards.

Overview

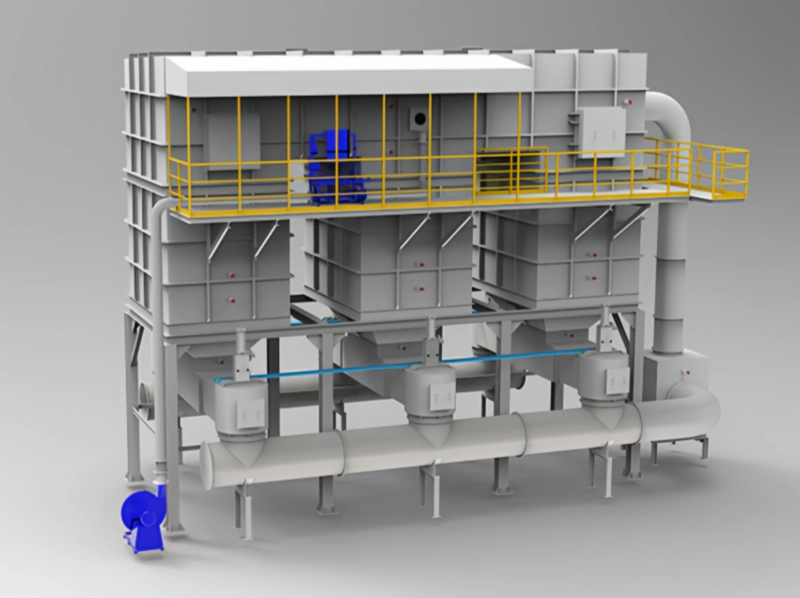

RTO (Regenerative Thermal Oxidizer) is a highly efficient waste gas treatment device widely used in industrial waste gas treatment. RTO technology utilizes the principle of high-temperature oxidation, converting harmful gases into harmless substances such as carbon dioxide and water through the reaction of waste gas with oxygen. RTO not only boasts high-efficiency waste gas treatment capabilities but also features energy saving and environmental protection, making it particularly suitable for treating waste gases containing volatile organic compounds (VOCs), acidic gases, and other harmful gases.

🌍 Background of PM2.5 Control in the Netherlands

The Netherlands has long been committed to improving air quality, with PM2.5 being one of the key targets in the country’s environmental regulations. Based on the EU Air Quality Directive, the Dutch government has set strict air pollution emission standards, particularly in the industrial sector, requiring companies to reduce emissions of PM2.5 and other particulate matter.

Dutch Regulations

Dutch environmental regulations require all industrial emissions of PM2.5 to be kept within legal limits, and companies must be granted an environmental permit. According to the Dutch Environmental Management Act and Air Quality Standards, the annual average concentration of PM2.5 must not exceed 25 micrograms per cubic meter.

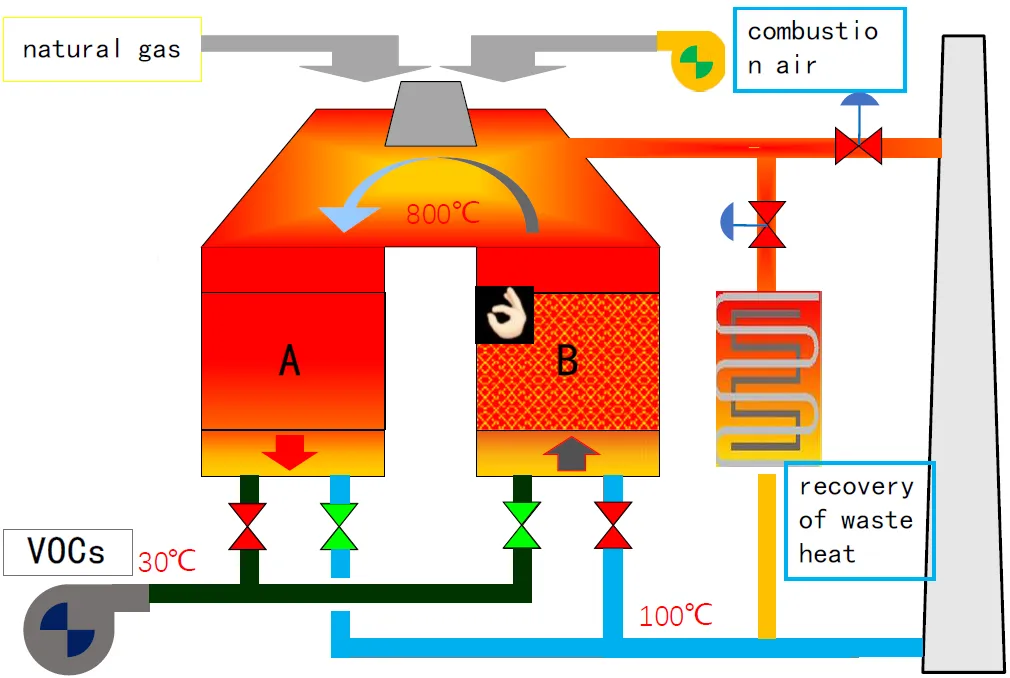

Workflow

🔍 Why Choose RTO Technology to Treat PM2.5?

RTO System Advantages

Advanced Solutions for Industrial Air Purification

High Removal Rate

RTO technology ensures complete elimination of particulates through high-temperature oxidation, strictly meeting Dutch and EU environmental emission standards.

Eco-Friendly & Saving

Beyond purification, the integrated thermal recovery system achieves high-efficiency energy utilization, significantly reducing operational costs.

Regulatory Alignment

Ensures full compliance with Dutch air quality regulations and NeR standards, helping enterprises avoid penalties and legal risks.

No Secondary Pollution

The process ensures that waste gases are converted into harmless substances like CO2 and water vapor, preventing any secondary environmental impact.

Main Applications of RTO

Expertise & Qualifications

Leveraging our collaboration with the National Engineering Laboratory for Volatile Organic Pollutant Control Materials and Technologies (Shaanxi Branch), jointly established with the University of Science and Technology of China and Xi’an Jiaotong University, we focus on research in thermal energy storage combustion technology and molecular sieve adsorption technology. As part of our global innovation efforts, we aim to create a shared technology research and development platform to promote cross-industry collaboration and progress, and to cooperate with leading institutions in the Netherlands and other EU countries.

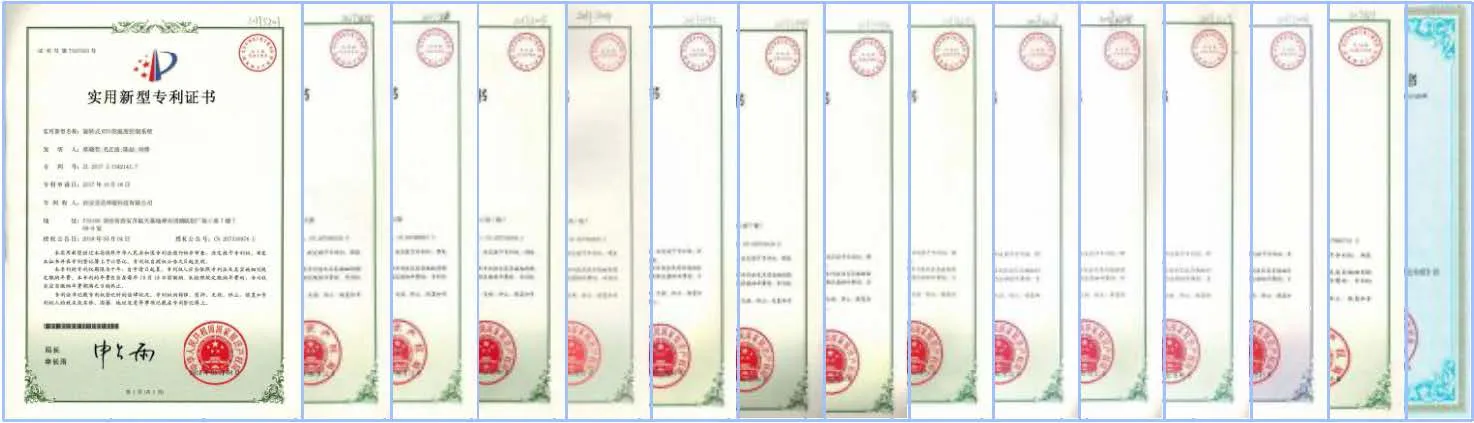

The company has registered a total of 48 patents, including 13 invention patents. Specifically, we have obtained 2 invention patents, 24 utility model patents, 5 design patents, and 4 software copyrights. These innovative achievements not only comply with EU environmental standards but also contribute to the development of sustainable technologies and the realization of the European Green Deal and the principles of the circular economy.

Case Sharing

A major industrial park in the Netherlands specializing in metal processing and chemical production faced severe challenges with particulate matter emissions exceeding Dutch and EU regulatory limits.

- Excessive PM2.5: High concentrations of fine particulates were unmanageable with existing infrastructure.

- Strict EU Norms: Pressure to meet the annual mean limit of 25 µg/m³.

- Operational Costs: Inefficient systems leading to unsustainable energy consumption.

Implemented high-temperature oxidation (800-1100°C) to convert hazardous particulates into CO2 and water vapor.

Integrated advanced heat recovery to preheat inlet gases, significantly lowering fuel dependency.

Removes moisture and VOCs to ensure the RTO operates at peak efficiency.

- Environmental: PM2.5 emissions successfully reduced to well below EU limits.

- Economic: Achieved a 20% reduction in overall energy costs for waste gas treatment.

- Compliance: Fully verified and approved by Dutch environmental regulators, enhancing the park's market reputation.