Industrial Kiln Treatment Solutions

Emissions from industrial furnaces present distinct treatment challenges due to their characteristic low oxygen content, which hinders combustion efficiency, and high concentrations of carbon monoxide (CO)—a toxic pollutant requiring strict control. Effective abatement is essential to meet environmental standards and protect public health. RP Techniek BV offers robust, customized solutions designed to efficiently treat such hard-to-handle gases, ensuring reliable compliance and operational safety.

- Exhaust gas characteristics: Low oxygen content, high carbon monoxide concentration.

- Exhaust gas components: Carbon monoxide.

- Process solution: Air distribution system + rotary RTO + waste heat recovery (steam, hot water, thermal oil)

Steel plant exhaust gas treatment

Lime kiln exhaust gas treatment

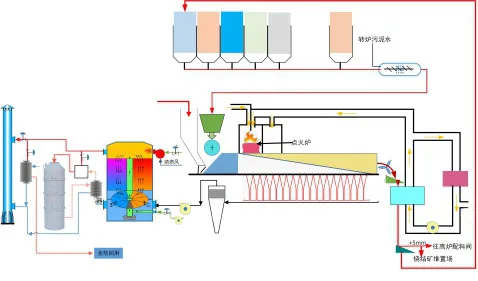

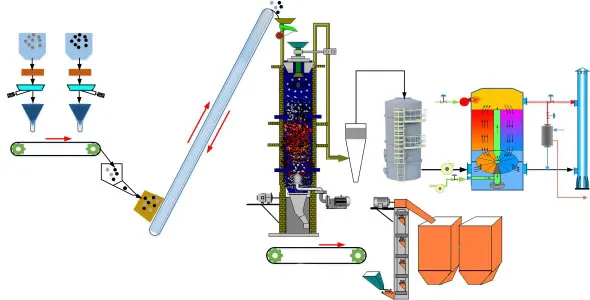

Process Scheme

To effectively tackle these challenges, the proposed waste gas treatment system integrates the following core components:

1. Air Distribution System

The air distribution system is essential for enhancing combustion efficiency by introducing supplemental oxygen into the waste gas stream. This promotes complete oxidation of CO into less harmful carbon dioxide (CO₂). Uniform air distribution throughout the combustion chamber helps minimize CO formation and improves temperature consistency, leading to more stable and efficient operation.

2. Regenerative Thermal Oxidizer (RTO)

The RTO serves as the core treatment unit for eliminating volatile organic compounds (VOCs) and carbon monoxide (CO). Operating within a temperature range of 750°C to 900°C, it facilitates the oxidation of CO into CO₂. A key feature of the RTO is its ability to recover and reuse heat from the treated gas to preheat incoming emissions, greatly improving energy efficiency.

3. Waste Heat Recovery

To enhance energy utilization and reduce operating expenses, the system incorporates a waste heat recovery unit that captures residual thermal energy from the cleaned gas. This energy is repurposed in three principal forms:

- Steam Recovery: Generates steam for use in heating, drying, or power generation processes.

- Hot Water Recovery: Produces hot water suitable for space heating, cleaning, or other thermal duties.

- Thermal Oil Recovery: Heats transfer oil for high-temperature industrial applications requiring consistent heat delivery.

By incorporating these elements, the treatment system effectively reduces CO emissions while simultaneously boosting energy efficiency and lowering operational costs. This integrated approach supports both environmental goals and the long-term sustainability of industrial activities.