Coating Industry Treatment Solutions

Building on the proven success of RP Techniek BV’s rotary RTO technology—already widely adopted in VOC management for automotive coating and surface painting operations—our solutions deliver robust and efficient emissions control for the coating industry.

At present, RP Techniek BV rotary RTO has been widely used in VOCs management of automobile coating, surface painting and other enterprises.

- Characteristics of waste gas: large air volume and low concentration

- Waste gas components: toluene, xylene, butanol, aromatic naphtha, methyl isobutyl ketone, butyl acetate, ethylene glycol butyl ether, ethylbenzene, acetone

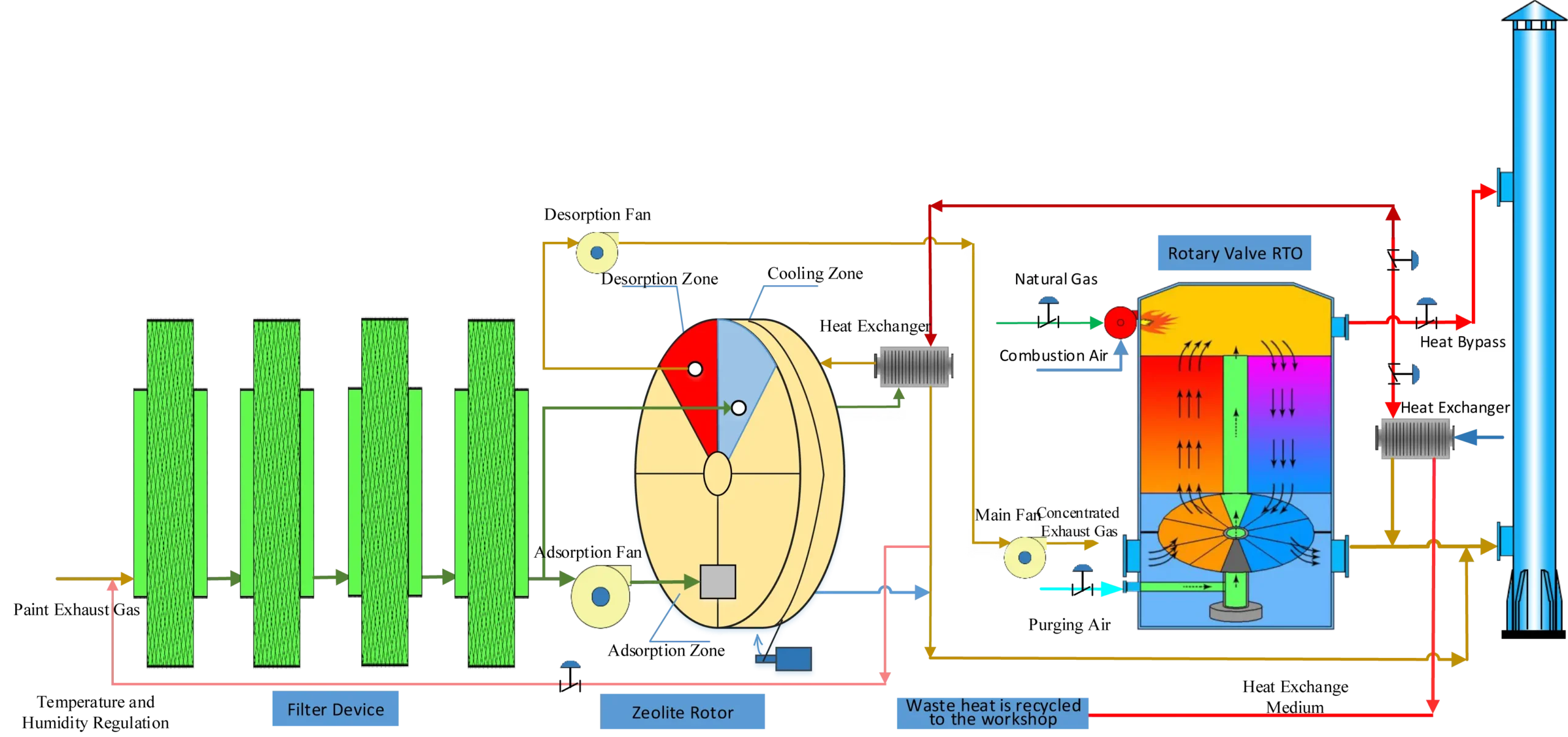

- Process scheme: filtration + zeolite rotor concentration + rotary RTO

- Waste gas concentration: 200mg/m³~400mg/m³

- Emission limit: NMHC≤50mg/m³

Coating Industry 3D drawing

System diagram of VOCs treatment and waste heat recycling in coating industry

Process Design for Efficient Treatment

To efficiently control these pollutants, the proposed treatment system employs a multi-stage approach aimed at optimizing performance and adhering to emission regulations:

- Filtration Stage: The process begins with filtering the waste gas to eliminate particulate matter and larger contaminants. This initial phase is essential for safeguarding downstream equipment and improving overall system performance.

- Zeolite Rotor Concentration: Due to the low concentration of VOCs, a zeolite rotor concentrator is used to adsorb and concentrate these compounds. Zeolites serve as highly efficient adsorbents that selectively capture VOCs, increasing their concentration for more effective treatment in later stages.

- Rotary RTO Treatment: The concentrated VOCs are then processed in a regenerative thermal oxidizer (RTO), where they are thermally oxidized at elevated temperatures. This treatment efficiently decomposes VOCs into harmless outputs such as carbon dioxide and water vapor, substantially minimizing environmental emissions.

Emission Standards and Compliance

Environmental regulations impose strict limits on non-methane hydrocarbons (NMHC) in emissions, with a typical threshold of ≤50 mg/m³. The Yurcent rotary RTO system is engineered to not only meet but often exceed these requirements, ensuring full compliance with environmental standards.

By implementing the Yurcent rotary RTO system, industrial operations can effectively reduce VOC emissions, decrease their environmental impact, and consistently adhere to regulatory demands. This integrated strategy addresses immediate emission challenges while supporting broader sustainability objectives within the coating sector.