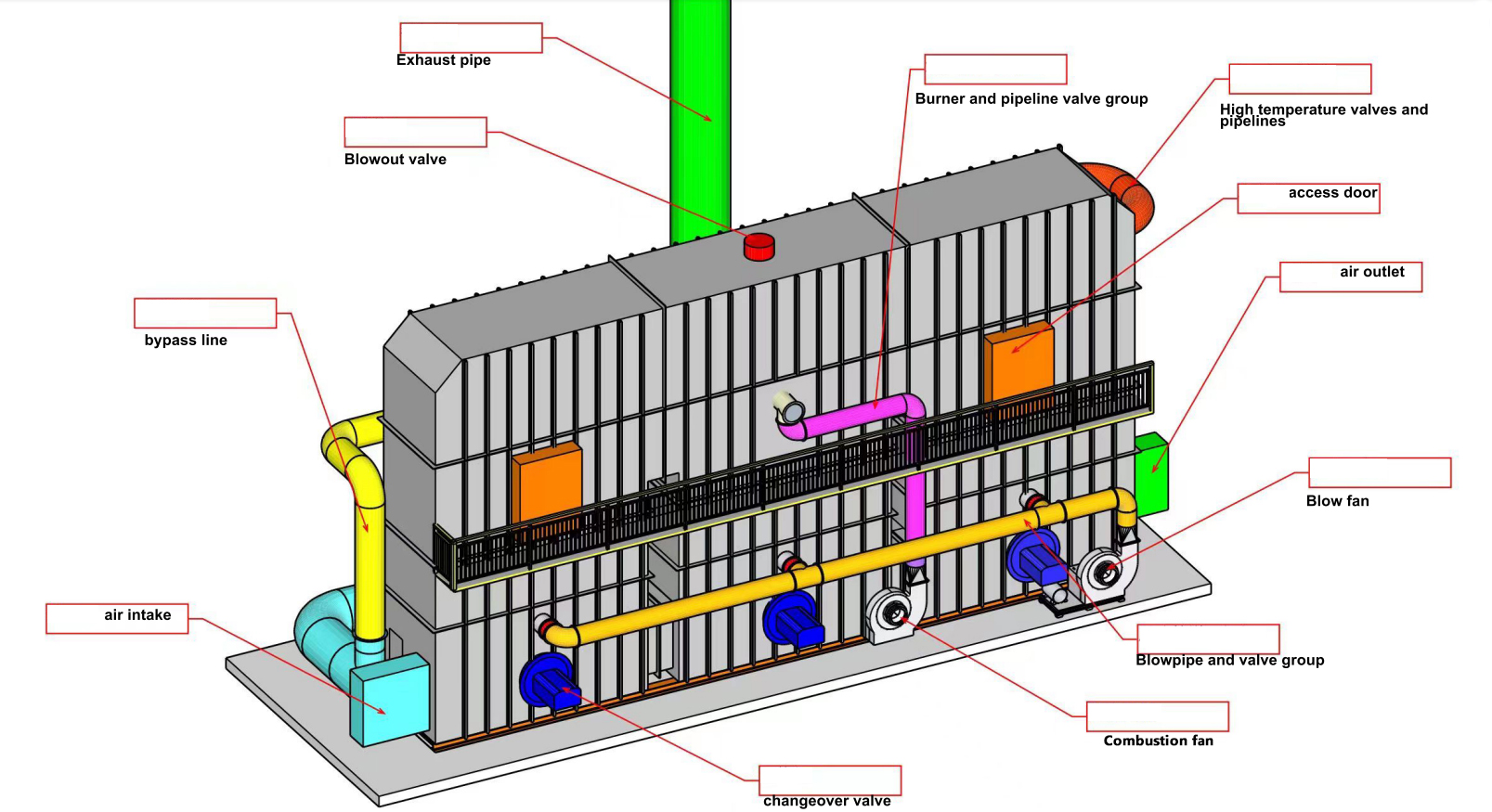

من قنوات أمستردام المتشعبة، حيث كان تجار القرن السابع عشر يتاجرون بالأوراق والأصباغ النادرة، إلى أراضي فليفولاند الشاسعة المستصلحة بعزيمة لا تلين، لطالما نسجت هولندا الابتكار في نسيج تجارتها وحرفها. تقدم شركة إيفر-باور أنظمة مؤكسدة حرارية متجددة (RTO) مصممة خصيصًا لعمليات التغليف والطلاء والتزجيج، حيث تترابط الطبقات لتكوين عبوات وتشطيبات متينة تتحمل أمطار البلاد الغزيرة ورياحها العاتية. تعالج هذه الوحدات أبخرة المواد اللاصقة والمذيبات، مسترجعةً الحرارة لتشغيل العمليات الجارية، تمامًا كما كانت طواحين الهواء الهولندية تطحن الحبوب وتضخ المياه للحفاظ على الحياة في الأراضي المستصلحة.

في بلدٍ تتنقل فيه الدراجات الهوائية عبر الجسور التاريخية، وتُعدّ فيه صادرات زهور التوليب رمزًا للتجارة المزدهرة، يُؤمّن التغليف المرن عبوات مرنة لأجبان غودا، بينما يحمي الطلاء والتزجيج ملصقات زجاجات هاينكن المُشحونة عالميًا. تعمل تقنية الأكسدة الحرارية المتجددة (RTO) لدينا على التقاط المركبات المتطايرة الناتجة عن هذه العمليات، مما يضمن تشغيل المنشآت في موانئ حيوية مثل روتردام دون أي تأثير سلبي على البيئة، مُجسّدةً بذلك المبدأ الهولندي للتعاون القائم على "نموذج البولدر"، حيث يتحد أصحاب المصلحة من أجل الصالح العام، مُحوّلين النفايات المُحتملة إلى طاقة قيّمة.

بالتدقيق، نجد أن هذه الأنظمة تتضمن خصائص تتناسب مع الكفاءة الهولندية، مثل التصاميم الانسيابية التي تتلاءم مع المستودعات الصغيرة في لاهاي. هناك، حيث يؤثر التاريخ البحري على الخدمات اللوجستية العالمية، تتعامل مراكز عملياتنا مع الزيادات المفاجئة في عمليات التغليف السريع لأغلفة التصدير أو تغليف المواد الترويجية، وتحافظ على استقرارها خلال فترات الذروة الموسمية المرتبطة باحتفالات يوم الملك أو شحنات العطلات.

المعايير الفنية الرئيسية لعملية إعادة التشكيل الحراري في التغليف والطلاء والتزجيج

للحصول على نظرة معمقة حول إمكانيات النظام، راجع هذه المعايير التقنية الرئيسية الـ 31 المُحسّنة لعمليات التغليف والطلاء والتزجيج. وهي تعالج الأبخرة الغنية بالمواد اللاصقة في التغليف، وأحمال المذيبات في الطلاء، وبقايا الورنيش في التزجيج، مع تضمين تحسينات عام 2025 من التحديثات الأخيرة لأفضل التقنيات المتاحة في الاتحاد الأوروبي بشأن الاستعادة الهجينة للركائز المتغيرة.

| المعلمة | القيمة/النطاق | وصف |

|---|---|---|

| كفاءة تدمير المركبات العضوية المتطايرة (DRE) | 99.2% | كفاءة في أكسدة المواد اللاصقة والورنيش إلى غازات غير ضارة. |

| استعادة الطاقة الحرارية (TER) | 97% | معدل استعادة الحرارة من العادم لإعادة تسخين بكرات التغليف. |

| معدل تدفق غاز العملية | 12,000 – 140,000 متر مكعب قياسي/ساعة | قدرة مرنة لسرعات خطوط الطلاء المتغيرة. |

| درجة حرارة التشغيل | 770-870 درجة مئوية | درجة حرارة الاحتراق اللازمة للتفكك الكامل لمركبات التزجيج. |

| مدة الإقامة | 1.3 ثانية | مدة بقاء الغاز تضمن التدمير الكامل لبخار المادة اللاصقة. |

| انخفاض الضغط | 140-320 باسكال | الحد الأدنى من إعاقة التدفق لعمليات تركيب الزجاج بسلاسة. |

| السعة الحرارية للوسائط الخزفية | 1250 كيلوجول/م³·كلفن | تخزين الحرارة لدورات الطلاء المتقلبة. |

| دورة تبديل الصمام | 80-140 ثانية | توقيت انعكاس التدفق في التكوينات متعددة الطبقات. |

| انبعاثات أكاسيد النيتروجين | <35 ملغم/م³ | مستويات منخفضة من خلال الحرق الأمثل للمنشآت الحضرية. |

| انبعاثات ثاني أكسيد الكربون | <70 ملغم/م³ | عملية أكسدة لاحقة مضبوطة لإطلاق آمن. |

| تحمل رطوبة العادم | حتى 85% RH | يتحمل الرطوبة الناتجة عن الطلاءات المائية. |

| إزالة الجسيمات | 94% (مرشح أولي) | يلتقط البقايا قبل أكسدة التغليف. |

| استهلاك الوقود الإضافي | 0.3-1.1 متر مكعب من الغاز الطبيعي لكل 1000 متر مكعب من العادم | كفاءة في هولندا الواعية بالموارد. |

| وقت تشغيل النظام | 97.5% | موثوق به لخطوط التعبئة والتغليف المستمرة. |

| بصمة أرضية | 22-55 متر مربع | حلٌّ موفر للمساحة في المناطق الصناعية الكثيفة. |

| وزن | 18-45 طنًا | تصميم متين للاستخدام طويل الأمد. |

| استهلاك الطاقة | 55-220 كيلوواط | متوسط بالنسبة للمراوح وأجهزة التحكم. |

| مستوى الضوضاء | <78 ديسيبل (A) | هادئ بما يتناسب مع المناطق السكنية المجاورة. |

| مواد البناء | الفولاذ المقاوم للصدأ 304L | مقاوم للمواد المسببة للتآكل في الورنيش. |

| الحماية من الانفجار | معتمد من ATEX Zone 1 | السلامة في البيئات التي تكثر فيها المواد اللاصقة. |

| نظام التحكم | نظام سكادا مع واجهة المستخدم الرسومية | مراقبة متطورة لعمليات دقيقة. |

| فترة الصيانة | كل 7 أشهر | فحص الصمامات في تجهيزات التزجيج. |

| عمر الوسائط الخزفية | 9-14 سنة | يدوم لفترة أطول مع الصيانة المناسبة. |

| نوع المبادل الحراري | سيراميك على شكل خلية نحل | كفاءة عالية في نقل الحرارة أثناء الطلاء. |

| نسبة الرفض | 11:1 | القدرة على التكيف مع عمليات التغليف بالصفائح على دفعات. |

| وقت بدء التشغيل | 35-65 دقيقة | سريع لجدولة مرنة. |

| طريق الطوارئ الالتفافي | نظام أمان تلقائي في حالة الفشل | احمِ المنتج أثناء ذروة تركيز المذيب. |

| أجهزة استشعار المراقبة | المركبات العضوية المتطايرة، درجة الحرارة، التدفق | في الوقت الفعلي للامتثال للوائح التنظيمية. |

| تركيز المركبات العضوية المتطايرة عند المدخل | حتى 12 غ/م³ | يستوعب أحمال المواد اللاصقة المستخدمة في الطلاء. |

| تركيز المركبات العضوية المتطايرة في مخرج الهواء | <15 ملغم/متر مكعب | يلتزم بالحدود الهولندية الصارمة. |

| تكوين السرير | 2-4 أسرّة | نظام متعدد الطبقات لتركيب الزجاج بشكل ثابت. |

توضح هذه المعايير كيف تم تصميم وحدات RTO الخاصة بنا لتناسب تعقيدات التغليف والطلاء والتزجيج، حيث تتطلب المواد اللاصقة تدميرًا قويًا، والطلاءات تدفقات ثابتة، والتزجيج تعديلات سريعة، مع دمج تقنية 2025 الهجينة من تحديثات PPWR.

خصائص عمليات الترقق والطلاء والتزجيج في هولندا

تُساهم عملية التغليف بالرقائق في ربط الطبقات لتوفير تغليف متين، بينما تُطبّق عملية الطلاء أغشية واقية، وتُضفي عملية التزجيج لمعانًا على المطبوعات، وهي عمليات حيوية في بلدٍ تتطلب فيه الصادرات، مثل أغلفة الجبن من إيدام أو صناديق الزهور من آلسمير، تشطيبات متينة لمقاومة رطوبة هواء بحر الشمال. وقد ساهمت البراعة الهولندية، التي تجلّت في طباعة الخرائط خلال العصر الذهبي، في تشغيل خطوط إنتاج عالية السرعة في أوتريخت، ممزوجةً بين التقاليد والأتمتة.

تختلف خصائص العادم: فالتغليف يُطلق أبخرة لاصقة، والطلاء رذاذ مذيب، والتزجيج جزيئات ورنيش. في زيلاند الساحلية، يُسرّع هواء البحر المالح التآكل، لذا تتميز الأنظمة بسبائك مُحسّنة. يتطلب تباين الإنتاج - من تعبئة الزهور بكميات كبيرة في شمال هولندا إلى الملصقات المُخصصة في جنوب هولندا - استخدام أنظمة معالجة حرارية مُعاد تدويرها بنسب واسعة، للحفاظ على فعاليتها طوال مواسم تصدير زهور التوليب.

فيديو: عرض تشغيلي لجهاز RTO في خط طلاء في روتردام، يلتقط عملية التعامل مع بخار المادة اللاصقة أثناء تغليف مواد التعبئة والتغليف للتصدير.

بالإضافة إلى ذلك، فإن التحول إلى المواد اللاصقة الحيوية في ليمبورغ يقلل من المركبات العضوية المتطايرة ولكنه يدخل مواد عضوية، والتي تعالجها أجهزة التنظيف المسبق لدينا بشكل فعال، مما يرتبط بمبادرات الاستدامة الوطنية مثل المرونة التكيفية لشركة دلتا ووركس.

مقارنة العلامات التجارية في تكنولوجيا RTO

يُظهر التدقيق في خيارات الأكسدة الحرارية المتجددة لهذه العمليات تبايناتٍ واضحة. تتميز طرازات Dürr™ بقابلية التوسع لتناسب خطوط الطلاء الكبيرة، ولكنها قد تحتاج إلى تعديلات لمعالجة لزوجة ورنيش التزجيج. أما طرازات Anguil™ فتتعامل بكفاءة مع غبار التغليف، إلا أن طبقاتها قد تتكتل في الظروف الرطبة في هولندا. (ملاحظة: جميع أسماء الشركات المصنعة وأرقام القطع هي لأغراض مرجعية فقط. EVER-POWER شركة مصنعة مستقلة.)

تتميز تقنية Ever-Power بوسائط 18% المقاومة للبقايا بفضل 2025 طبقة مضادة للالتصاق، مما يجعلها مثالية للتغليف الذي يتطلب استخدام كميات كبيرة من المواد اللاصقة. مقارنةً بتقنية Tecam™، تتحمل صماماتنا 1.3 مليون دورة تشغيل، مما يقلل من حالات التوقف في مصانع أيندهوفن ذات الإنتاجية العالية. وقد تم إثبات ذلك من خلال اختبارات أجريت في بيئات رطبة مماثلة.

تركز بعض العلامات التجارية الآسيوية على القدرة على تحمل التكاليف ولكنها تغفل شهادات الاتحاد الأوروبي؛ تقدم Ever-Power امتثالاً كاملاً لمعايير IED BAT مع عمليات التحقق المحلية.

المكونات الأساسية وقطع الغيار والمواد الاستهلاكية

تتكون المكونات المركزية من صمامات قرصية مصنوعة من الفولاذ المقاوم للصدأ 304L لمقاومة التآكل، مع قطع غيار يتم استبدالها كل ثلاثة أشهر وتدوم من 5 إلى 7 سنوات. تعمل هذه المكونات على توجيه التدفقات بدقة. أما خلايا السيراميك على شكل قرص العسل، وهي مواد استهلاكية تُستخدم كوسط عازل للحرارة، فيتم استبدالها كل 9 إلى 14 عامًا للحفاظ على كفاءة نقل الطاقة.

تشمل الأجزاء الرئيسية مواقد بدء التشغيل، مع فوهات كقطع غيار سريعة الاستبدال تحافظ على اللهب. مرشحات رذاذ التغطية هي مواد استهلاكية قابلة للتنظيف، وتدوم لمدة 16 شهرًا. أما الأختام والحشيات، الضرورية للاحتواء، فهي مواد استهلاكية تخضع لفحص ربع سنوي، وتقاوم الرطوبة الهولندية.

تتميز هذه المجموعة بمراوح نقل الحركة، ومكونات مصممة لتحمل الاهتزازات لمدة 55000 ساعة. تشكل هذه المكونات مجتمعةً مجموعة متينة، مع توفر قطع غيار جاهزة تقلل من وقت التوقف في مواقع تصنيع الرقائق سريعة الإنتاج مثل مستودعات لايدن التاريخية.

التجارب الشخصية ودراسات الحالة

استلهامًا من مشروع تركيب في هارلم، يعكس إرث رامبرانت في الطباعة، قمنا بتجهيز خط تغليف زجاجي للصناديق الفاخرة. تسبب تراكم الورنيش الأولي في تلوث الوسائط، ولكن إعادة التصميم باستخدام كتل منظمة أدت إلى استقرارها، مما خفض انبعاثات المركبات العضوية المتطايرة بمقدار 99%، وأعاد توجيه الحرارة لتسخين أجهزة الطلاء مسبقًا، مما قلل استهلاك الطاقة بمقدار 33% وسط ارتفاعات الأسعار، تمامًا كما يفعل التجار الهولنديون الأذكياء الذين يحسنون طرق التوابل.

في تيلبورغ، واجه مصنعٌ لتغليف المواد مشكلة انبعاث الأبخرة اللاصقة؛ وقد ساهم استخدام أجهزة تنقية الغازات في حل المشكلة، ورفع وقت التشغيل إلى 97%. ولاحظ فريق العمل سهولة الصيانة، مما سمح بالتركيز على الجودة، على غرار طواحين الهواء التي تُخفف من أعباء العمل في الأراضي المستصلحة. وفي بريدا، تم تطوير طلاء مُخصص للتصدير مُعدّل خصيصًا للحد من انبعاثات المذيبات، مما أدى إلى روابط متجانسة وإشادة محلية بانخفاض الرائحة، وهو ما يُحاكي جهود هيئات المياه التعاونية.

في مدينة أنتويرب البلجيكية المجاورة، قامت شركة akin بتثبيت أنظمة تتوافق مع القواعد العابرة للحدود، وتخفف من حدة المشكلة 98% باستخدام الحرارة للتجفيف، مما يؤكد جدوى المرافق الإقليمية.

التكامل بين تحسين محركات البحث المحلي والعالمي: الصناعات واللوائح والقضايا

في هولندا، تزدهر عمليات التغليف والطلاء والتزجيج في شمال هولندا (عبوات أمستردام الفاخرة)، وجنوب هولندا (صادرات روتردام)، وأوترخت (المواد الترويجية)، وشمال برابانت (طلاءات أيندهوفن التقنية). وتُبرز عبارات مثل "التغليف بتقنية RTO في أمستردام" أو "التحكم في المركبات العضوية المتطايرة في طلاء روتردام" متطلبات كل منطقة. ويحدد مرسوم الأنشطة الهولندي سقفًا للمركبات العضوية المتطايرة أقل من 35 ملغم/م³، وفقًا لتوجيهات الاتحاد الأوروبي بشأن الانبعاثات الصناعية 2010/75/EU، مما يدفع باتجاه استخدام أفضل التقنيات المتاحة للتغليف بتقنية RTO عند مستوى 99% DRE. وتُظهر حالات من خيلدرلاند كيف حققت الشركات هذا الهدف من خلال تقنياتنا، مما ساهم في الحد من الروائح في خطوط إنتاج أرنهيم.

الدول المجاورة: بلجيكا (VLAREM <20 ملغم/م³ للطلاء)؛ ألمانيا (TA Luft NOx <85 ملغم/م³). لوكسمبورغ (الاتحاد الأوروبي يركز على استعادة المركبات العضوية المتطايرة). فرنسا (ICPE 97%) كفاءة؛ المملكة المتحدة (EA) تصاريح مكافئة للعبوات الناسفة المرتجلة.

على الصعيد العالمي، تشمل الدول الرائدة: الولايات المتحدة الأمريكية (وكالة حماية البيئة الأمريكية، معايير الانبعاثات الوطنية للملوثات الخطرة في الهواء، صناديق التعبئة في كاليفورنيا)؛ الصين (المعيار البريطاني 37822-2019، تغليف شنغهاي)؛ اليابان (قانون الهواء، زجاج طوكيو)؛ كوريا الجنوبية (الهواء النظيف، طلاء بوسان)؛ كندا (وكالة حماية البيئة الكندية، تغليف أونتاريو)؛ أستراليا (البرنامج الوطني لإدارة الملوثات، زجاج سيدني)؛ الهند (المجلس المركزي لمكافحة التلوث، طلاء مومباي)؛ البرازيل (المجلس الوطني لمكافحة التلوث، تغليف ساو باولو)؛ المكسيك (المعيار الوطني للمعايير 121، زجاج مدينة مكسيكو)؛ تركيا (لوائح الهواء، طلاء إسطنبول)؛ بولندا (الجهاز المبتكر، تغليف وارسو)؛ إيطاليا (الجهاز المبتكر، زجاج ميلانو)؛ إسبانيا (الجهاز المبتكر، طلاء برشلونة)؛ البرتغال (الجهاز المبتكر، تغليف لشبونة)؛ جمهورية التشيك (الجهاز المبتكر، زجاج براغ)؛ المجر (الجهاز المبتكر، طلاء بودابست)؛ النمسا (الجهاز المبتكر، تغليف فيينا)؛ سويسرا (قيمة انعكاس الضوء، زجاج زيورخ)؛ الدنمارك (الجهاز المبتكر، طلاء كوبنهاغن)؛ السويد (الجهاز المبتكر، تغليف ستوكهولم)؛ النرويج (قانون التلوث، زجاج أوسلو). فنلندا (IED، طلاء هلسنكي)؛ أيسلندا (EEA، تغليف ريكيافيك)؛ أيرلندا (IED، زجاج دبلن)؛ اليونان (IED، طلاء أثينا)؛ السعودية (PME، تغليف الرياض)؛ الإمارات العربية المتحدة (EAD، زجاج دبي)؛ جنوب أفريقيا (AQA، طلاء جوهانسبرج)؛ إندونيسيا (KLHK، تغليف جاكرتا).

تساهم اللوائح في دفع عجلة التغيير: يتطلب الاتحاد الأوروبي من شركات النقل الإقليمية استعادة أكثر من 971 طنًا من الانبعاثات؛ وخفضت حالات نيويورك الأمريكية انبعاثات المركبات العضوية المتطايرة بمقدار 991 طنًا. وقامت مقاطعة قوانغدونغ الصينية بتركيب نظام للحد من الانبعاثات بمقدار 981 طنًا، مما وفر 351 طنًا من الطاقة؛ والتزمت ريو البرازيلية باللوائح، مع توفير الحرارة اللازمة للربط.

تُظهر هذه الروابط شركة Ever-Power كشريك عالمي، مع كفاءة في المناطق الهولندية مثل فريزلاند (السترات الساحلية) وليمبورغ (الرقائق المبتكرة).

وبمزيد من البحث، تشمل تعديلات التغليف في أوفرايسل زيادة استعادة المواد لشبكات الربط، مما يمنع الفاقد. وترتبط مخرجات الطاقة بالشبكات الوطنية، مما يعزز الاستدامة المشتركة على غرار النقابات التاريخية.

تُظهر التحليلات الاقتصادية عائدًا على الاستثمار لمدة عامين ونصف من خفض استهلاك الوقود، وهو ما يتناسب مع الشركات الهولندية المقتصدة. ويستند التدريب إلى معايير السلامة البحرية، مع التركيز على إجراءات التعامل مع المواد اللاصقة.

التوسعات العالمية: طوكيو اليابانية تُركز على الزجاج الدقيق؛ بوسان الكورية الجنوبية تُركز على متانة التغليف. سيدني الأسترالية تُركز على المرونة في مختلف الظروف الجوية.

تشمل الابتكارات دورات معدلة بالذكاء الاصطناعي، تتنبأ بأحمال الورنيش لتوفير الوقود وخفض النفقات. كما تشمل أنظمة هجينة مزودة بممتصات للحد من ذروة استهلاك الوقود في المناطق الحساسة.

يُسهم التبديل وتوافر قطع الغيار في دعم العمليات الصغيرة في جرونينجن. كما تُعزز أوجه التآزر بين دوسلدورف الألمانية بموجب اتفاقيات الاتحاد الأوروبي التكنولوجيا العابرة للحدود.

في جوهر الأمر، فإن تحويل الأبخرة إلى حرارة يوازي شبكات القنوات الهولندية التي توجه المياه بشكل مفيد، مما يعزز إرث التغليف الأخضر.

آخر الأخبار حول خدمات التصنيع في قطاع التغليف والطباعة الهولندي

ديسمبر 2025: شركة تحويل مواد تغليف في أمستردام تعتمد تقنية الأكسدة الحرارية المتجددة المتقدمة، مما يقلل انبعاثات المركبات العضوية المتطايرة (38%) في إطار جهود الاتحاد الأوروبي لدعم برنامج PPWR. المصدر: NL Packaging Insights.

نوفمبر 2025: شركة زجاج من روتردام تندمج مع شركة بيري، مُدمجةً منظمة نقل إقليمية (RTO) لتصدير مستدام. المصدر: Dutch Print Update.

أكتوبر 2025: مصنع طلاء في أيندهوفن يختبر الجيل الجديد من تقنية إعادة تدوير المواد، بما يتماشى مع أهداف برابانت للاقتصاد الدائري. المصدر: مجلة التغليف الهولندية.

تواصل مع فريقنا للحصول على تصميم مخصص هيئة النقل الإقليمية خطة لدعم نجاحك.