RTO Odor Gas Treatment Solution

We provide RTO regenerative thermal oxidation solutions compliant with NEN-EN 13725 standards for the Netherlands’ strict odor regulations (Geurhinder).

Definition and origin of Odor Gas

Odor gases refer to all gaseous pollutants that can irritate the human olfactory organs, causing unpleasant sensations and adversely affecting the living environment. Their core characteristic is not toxicity, but rather the degree of olfactory disturbance they cause.

Key criteria:

- Subjective perception: Relies on human olfactory perception

- Low concentration sensitivity: Many substances can be detected at extremely low concentrations (ppb level)

- Environmental disturbance: Affects quality of life and environmental comfort

🏭 Industrial Sources (Key Governance Areas, Main Application Fields of RTO)

| Industry Type | Typical Generation Stages | Main Malodorous Substances | Odor Description |

|---|---|---|---|

| Wastewater Treatment | Grit chamber, sedimentation tank, sludge treatment | H2S, NH3, methyl mercaptan, amines | Rotten egg smell, pungent ammonia odor |

| Waste Processing | Stacking, compression, leachate | Sulfides, fatty acids, aldehydes/ketones, VOCs | Rotten mixed odor |

| Chemical & Pharmaceutical | Reaction kettles, storage tanks, wastewater ponds | Halogenated hydrocarbons, sulfide ethers, organic amines, benzene series | Chemical irritant odor |

| Food Processing | Fermentation, cooking, waste materials | Fatty acids, aldehydes, sulfur-containing amino acid decomposition products | Rancid, putrid odor |

| Livestock & Poultry Breeding | Manure, urine, feed storage | NH3, H2S, skatole, VFAs | Pungent manure/urine odor |

| Petroleum Refining | Desulfurization, catalytic cracking, storage and transportation | Mercaptans, sulfides, phenols | Rotten egg smell, tar odor |

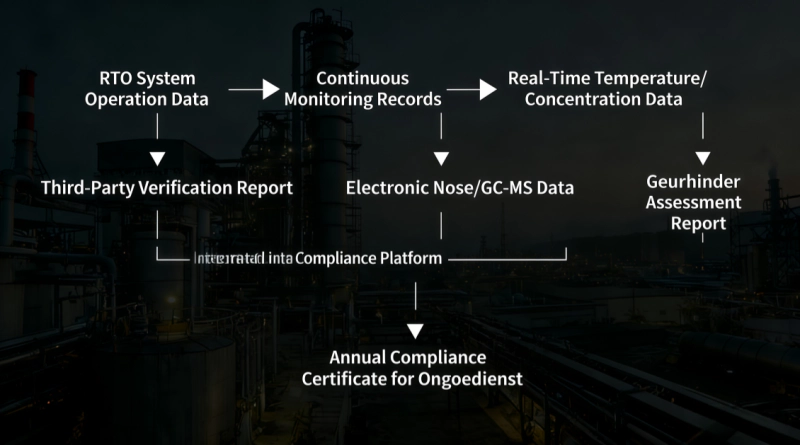

How do we ensure gas emission compliance?

Our RTO Design Standards:

1. Ultra-High Removal Efficiency

Design Benchmark: >99% Odor Removal Rate

Actual Operation: Ensures emission concentration <1 ouE/m³ (below most detection limits)

Technical Guarantee: Oxidation temperature 760-850℃ + >0.75 seconds residence time

2. Netherlands-Specific Monitoring Integration

Integrated continuous odor monitoring system (e.g., electronic nose or online GC-MS)

Real-time data upload to Omgevingsdienst (Environmental Services Department) platform

Automatic generation of compliance reports, meeting ILT (Dutch Environmental Inspectorate) requirements

3. Design Adapted to the Dutch Climate

Low-Temperature Resistant Design: Ensures stable operation at -10℃

Wind and Rain Resistant: Meets NEN-EN 60529 IP protection standards

Corrosion-Resistant Materials: Resistant to the salt spray environment of the North Sea region

Customer Case

Case 1: FrieslandCampina Dairy Processing Plant

Challenge: Located in a sensitive agricultural area, the odor from cheese production caused complaints from surrounding residents.

Solution: Customized RTO system, focusing on the treatment of fatty acids and sulfides.

Compliance Results:

- Before: 15-20 times/month, monitoring value 5-8 ouE/m³

- After: 6 consecutive months of zero complaints, monitoring value 0.5-1.2 ouE/m³

- Repairing: Successfully renewed environmental permit, and approval obtained for expanded production scale.

Client Testimonial:

“The RTO installation did not cause any outstanding problems, but it did cause complaints from surrounding residents. Continued monitoring of these issues has led to further complaints.”

— Klaas van der Meer, Milieucoördinator

Case 2: Afvalverwerking Noord-Holland Waste Treatment Plant

Special Requirements: Must meet LAP3 (National Waste Management Plan) upgrade requirements

Technological Innovation: RTO + heat recovery power generation, integrated into the district heating network

Economic and Environmental Benefits:

Energies: Annual natural gas savings of 120,000 m³

CO2 Reduction: Annual emission reduction of 240 tons

Subsidy: Receive SDE++ subsidy of €85,000