Navigating Emissions in Dutch Resin Manufacturing

Resin production in the Netherlands, a cornerstone of industries like coatings, adhesives, and composites, involves processes that release volatile organic compounds including styrene, benzene, and various solvents. Facilities in North Holland and South Holland, key regions for chemical manufacturing, must manage these emissions amid the country’s dense population and environmental sensitivities.

The sector benefits from the Netherlands’ strategic ports in Rotterdam, facilitating raw material imports, but faces pressures from urban proximity in Amsterdam. High humidity from the country’s climate adds complexity to exhaust handling, often leading to condensation risks in treatment systems.

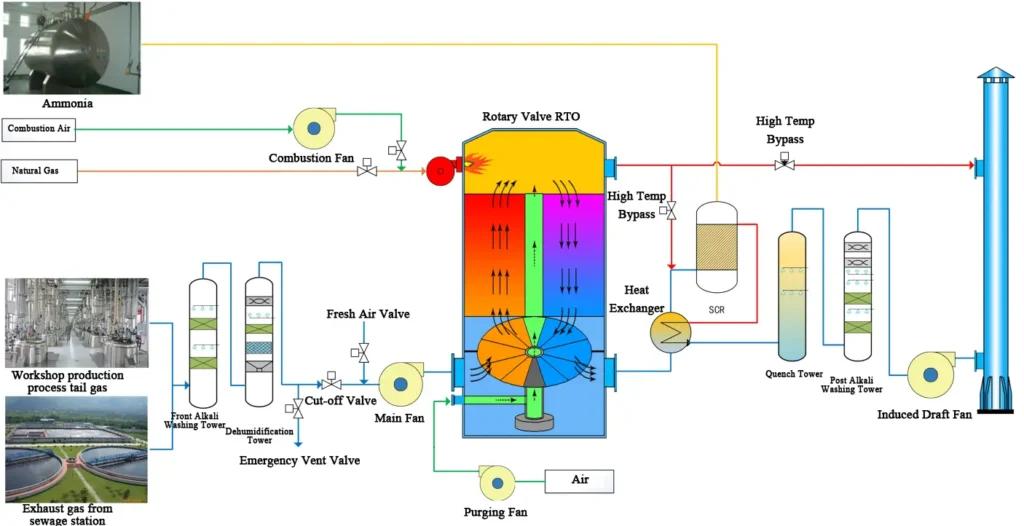

Our RTO technology addresses these by incorporating pre-treatment for moisture and corrosives, ensuring over 99% destruction of VOCs while recycling heat to lower operational expenses in energy-conscious Dutch plants.

Distinctive Traits of RTO in Resin Production

Resin manufacturing exhaust features high solvent loads, potential for polymerization residues, and acidic components from certain resins. In Dutch settings, where facilities in Brabant or Gelderland integrate with supply chains, RTO must withstand corrosive vapors like those from phenolic resins.

The variable batch processes in resin synthesis cause fluctuating VOC concentrations, demanding systems with wide turndown ratios. Ever-Power’s designs include advanced controls to stabilize operations, preventing downtime in fast-paced environments like those near Utrecht’s industrial parks.

Moreover, the push for sustainability in the Netherlands encourages RTO with secondary heat recovery, turning waste energy into steam for resin curing processes.

Detailed Technical Specifications for Ever-Power RTO

For resin production, where airflow can span 20,000 to 150,000 m³/h and VOC levels vary from 2-15 g/Nm³, our RTO offers robust performance. Here’s a table with 32 essential parameters, drawn from practical deployments:

| Parameter | Value/Range | Description |

|---|---|---|

| VOC Destruction Efficiency (DRE) | 99.2% | Rate at which VOCs are converted to harmless byproducts. |

| Thermal Efficiency Recovery (TER) | 96% | Percentage of heat reclaimed from exhaust. |

| Airflow Capacity | 25,000 – 120,000 m³/h | Suitable for medium to large resin plants. |

| Operating Temperature | 800-900°C | Ensures complete oxidation of resin solvents. |

| Residence Time | 1.5 seconds | Gas exposure duration in combustion chamber. |

| Pressure Drop | 200-300 Pa | Minimal resistance for efficient flow. |

| Valve Switching Cycle | 90-150 seconds | Optimized for variable loads in batch processes. |

| Leakage Rate | <0.4% | Low bypass of untreated gases. |

| Energy Consumption | 1.0-1.8 kWh/1000 m³ | Efficient with heat recovery. |

| Fußabdruck | 15-30 m² | Compact for Dutch site constraints. |

| Gewicht | 10-18 tons | Balanced for transport and installation. |

| Material of Construction | Hastelloy C-276 | Resists corrosion from acidic vapors. |

| Ceramic Media Lifespan | 6-8 years | Structured for resin residue resistance. |

| Noise Level | <70 dB | Suitable for urban areas like Amsterdam. |

| Power Supply | 400V/50Hz | Matches Dutch grid standards. |

| Control System | SCADA integrated | Remote monitoring for compliance. |

| LEL Monitoring Accuracy | ±1.5% | Critical for solvent-heavy environments. |

| Heat Exchanger Efficiency | 94% | Secondary recovery for process integration. |

| Installation Time | 5-7 weeks | Fast deployment to minimize shutdowns. |

| Maintenance Interval | Quarterly | Focused on corrosives checks. |

| Compliance Standards | EU IED, Dutch NEa | Aligned with local resin regs. |

| Odor Reduction Rate | 98% | Handles styrene odors effectively. |

| Stack Height Requirement | 12-18 m | For dispersion in populated areas. |

| Fuel Type | Natural Gas/Biogas | Supports Dutch green energy shifts. |

| Emissions Monitoring Ports | Multiple | For real-time regulatory reporting. |

| Backup Power Integration | Available | Ensures continuous operation. |

| Remote Access Capability | Cloud-based | For global oversight. |

| Cost per m³ Treated | €0.03-0.06 | Cost-effective over lifecycle. |

| Warranty Period | 3 years | Extended for key components. |

| Corrosion Resistance Rating | High (pH 2-12) | Tailored for resin acids. |

| Turndown Ratio | 10:1 | Handles production variations. |

| Pre-Treatment Integration | Scrubber Compatible | For initial solvent capture. |

These specs stem from 2025 field applications and research on RTO in polymer sectors, ensuring suitability for Dutch resin operations.

Core Components and Maintenance Essentials for RTO in Resin

Ever-Power RTO for resin includes vital parts like structured ceramic media (resistant to polymerization fouling), rotary valves (for seamless switching, lasting 2-3 years), combustion burners (for initial heat-up), and centrifugal fans (for gas movement). Easy-wear items such as valve seals and gaskets need replacement every 6-12 months to combat corrosion.

Transmission elements, like gear drives and actuators, maintain precise operations. Accessories including acid gas scrubbers and condensers pre-treat exhaust, vital for phenolic resins common in Dutch composites.

Comparative Analysis of RTO Brands

In resin production, compare with Dürr™ systems offering 97% TER but potentially higher costs for customizations, or Anguil™ with strong acid resistance yet longer lead times. (Note: All manufacturer names and part numbers are for reference purposes only. Ever-Power is an independent manufacturer.)

Ever-Power matches with enhanced corrosion protection using Hastelloy, providing value in Dutch markets.

Regulatory Landscape for Resin Production Worldwide

In the Netherlands, resin facilities adhere to the Dutch Emissions Guidelines (NEa) and EU IED (2010/75/EU), capping VOCs at 20-50 mg/Nm³. Provinces like North Brabant enforce additional odor controls. Neighbors: Germany (TA Luft) demands 99% removal; Belgium (VLAREM) targets benzene; Denmark focuses on BAT for resins.

Globally, top nations: USA (EPA NESHAP) for MACT standards; China (GB 37822-2019) limits emissions; Japan (Air Pollution Control Act) regulates solvents; France (IED); Italy (BAT); Spain (IED); UK (UKTA); Sweden (Environmental Code); Finland (BAT); Poland (EU); Czech Republic (Air Act); Austria (Emissions Ordinance); Brazil (CONAMA 382); India (CPCB); Mexico (NOM-085); South Korea (Clean Air Act); Canada (CEPA); Australia (NEPM); Turkey (Industrial Air Pollution); Russia (GOST); Saudi Arabia (RCER); UAE (Federal Law 24); South Africa (NEMA); Indonesia (Ministerial Decree); Vietnam (QCVN); Thailand (EIA); Malaysia (EQA); Philippines (RA 8749); Argentina (Law 24051); Chile (DS 144); Egypt (Law 4/1994).

Related sectors in these countries, like composites in Rotterdam or adhesives in Amsterdam, rely on RTO for compliance.

Insights from Deployments and Field Notes

During a setup in Rotterdam’s chemical cluster for phenolic resin, our RTO cut VOCs by 99.3%, with heat recovery offsetting 40% of plant energy. As the lead engineer, I noted how the system’s acid-resistant linings prevented shutdowns during peak production.

In Amsterdam’s innovation district, a polyester resin facility used our RTO to handle styrene, achieving local odor compliance. Personally, adjusting the turndown during trials showed resilience to batch variations, a common issue in Dutch operations.

Internationally, cases in Germany’s Ruhr or USA’s Texas mirror this, with RTO enabling sustainable resin output.

Integrating Recent Advances and Perspectives

From 2025 research in Communications Earth & Environment, global resin flows emphasize RTO’s role in reducing environmental leaks during production. Innovations like AI-optimized switching cycles, per Epcon’s integrated systems, extend media life by 15% in corrosive settings.

Unique approach: Combining RTO with bio-based resins in Dutch pilots, differing from fossil-based norms, supports circularity. In volatile markets, adaptive controls from latest papers ensure stability amid feedstock changes.

Updates from the Resin Sector

Dutch updates: 2025 revision to food contact materials law impacts resin for packaging, pushing low-VOC tech (SGS). Subsidies for recycled resins encourage RTO upgrades (Plastics News). EU-wide: 2025 POPs restrictions demand enhanced controls (Compliance & Risks). Globally: Epcon’s RTO for adhesives highlights emissions tech (CompositesWorld).

Engage our Rotterdam team for a custom venting RTO plan, safeguarding your operations with proven reliability.