In a nation where ingenuity has long tamed the seas and harnessed the winds, the Netherlands stands at the forefront of energy innovation, even as its own coal mines have faded into history. Drawing from a legacy of engineering prowess that built dikes against relentless North Sea tides, Ever-Power crafts specialized regenerative thermal oxidizer (RTO) systems for coal mine ventilation air methane (VAM) oxidation. These units transform dilute methane streams—once vented as waste—into harmless exhaust while recovering valuable heat, mirroring the Dutch tradition of turning challenges into resources, much like reclaiming land from water to create fertile polders.

Though the Netherlands phased out coal mining decades ago, its expertise in gas handling and emissions control extends globally, supporting partners in coal-rich regions through technology exports. In this context, our RTOs address VAM, the low-concentration methane (typically 0.1-1%) in mine ventilation air that poses explosion risks and contributes to greenhouse effects. By oxidizing this methane at high temperatures, systems prevent atmospheric release, aligning with Dutch commitments to methane abatement under EU frameworks, where precision engineering ensures safety in environments as unforgiving as the country’s storm-prone coasts.

Extending beyond basic oxidation, these setups include adaptations for the variable methane flows common in mining ventilation, with automated controls that adjust to fluctuating air volumes without compromising destruction rates. This reliability supports the Netherlands’ role in international energy transitions, where Dutch firms consult on global projects, applying lessons from North Sea gas fields to mitigate mining methane worldwide.

Key Technical Parameters for RTO in Coal Mine VAM Oxidation

To grasp the engineering backbone of these systems, examine these 32 pivotal technical parameters fine-tuned for VAM handling. They cater to the dilute, high-volume nature of ventilation air, ensuring stable operation in demanding mining contexts while drawing on recent advancements like enhanced ceramic media from 2025 studies on low-methane combustion.

| Parameter | Value/Range | Description |

|---|---|---|

| Methane Destruction Efficiency (DRE) | 98-99.9% | Percentage of methane oxidized into CO2 and H2O in dilute streams. |

| Thermal Energy Recovery (TER) | 92-97% | Heat recapture rate from exhaust for preheating incoming air. |

| Process Gas Flow Rate | 50,000 – 500,000 Nm³/h | Capacity for large ventilation volumes typical in coal mines. |

| Operating Temperature | 800-950°C | Combustion zone heat for complete low-concentration methane breakdown. |

| Residence Time | 1.5-2.5 seconds | Duration gases reside in chamber to ensure oxidation at low methane levels. |

| Pressure Drop | 200-400 Pa | System flow resistance, optimized for mine ventilation fans. |

| Ceramic Media Heat Capacity | 1,300 kJ/m³·K | Storage ability for heat in fluctuating methane conditions. |

| Valve Switching Cycle | 120-180 seconds | Interval for reversing flow in multi-bed designs to maintain stability. |

| NOx Emissions | <30 mg/Nm³ | Low output through staged combustion to meet mining air quality. |

| CO Emissions | <50 mg/Nm³ | Controlled levels post-oxidation for safe mine atmospheres. |

| Inlet Methane Concentration | 0.1-1.0% | Handles ultra-dilute VAM typical in ventilation air. |

| Particulate Matter Tolerance | Up to 10 mg/Nm³ | Efficiency with coal dust in exhaust streams. |

| Auxiliary Fuel Consumption | 0.2-0.8 Nm³ natural gas per 1,000 Nm³ air | Minimal addition for sustaining oxidation in lean methane. |

| System Uptime | 97% | Reliability crucial for continuous mine ventilation. |

| Fußabdruck | 30-80 m² | Compact for underground or surface mine installations. |

| Gewicht | 20-60 tons | Sturdy construction for harsh mining environments. |

| Power Consumption | 100-300 kW | Energy for blowers and controls in remote sites. |

| Noise Level | <90 dB(A) | Acceptable for worker safety in mine vicinities. |

| Material of Construction | High-Alloy Steel | Resistant to moisture and dust corrosion. |

| Explosion Protection | ATEX Zone 0 Certified | Essential for methane-rich mining zones. |

| Control System | PLC with Remote Monitoring | Automated adjustments for variable methane. |

| Maintenance Interval | Every 3 months | Checks for valves in dusty conditions. |

| Lifetime of Ceramic Media | 8-12 years | Durable against thermal cycling in VAM flows. |

| Heat Exchanger Type | Random Packed Ceramic | High void fraction for low-pressure drop. |

| Turndown Ratio | 15:1 | Flexibility for varying ventilation rates. |

| Start-up Time | 45-90 minutes | Gradual heat-up to prevent shocks. |

| Emergency Bypass | Fail-Safe Automated | Protects during methane surges. |

| Monitoring Sensors | CH4, Temp, O2 | Real-time methane and oxygen tracking. |

| Inlet Humidity Tolerance | Up to 100% RH | Manages moist mine air effectively. |

| Outlet Methane Concentration | <0.01% | Ensures near-complete abatement. |

| Bed Configuration | 3-5 Beds | Multi-bed for continuous operation. |

| Flame Arrestor Rating | Group IIA | Safety for methane gas groups. |

These parameters reflect integrations of 2025 advancements, like improved catalysts from recent UNECE studies, ensuring systems perform in the dilute methane regimes characteristic of VAM applications.

Characteristics of Coal Mine VAM Processes in the Netherlands Context

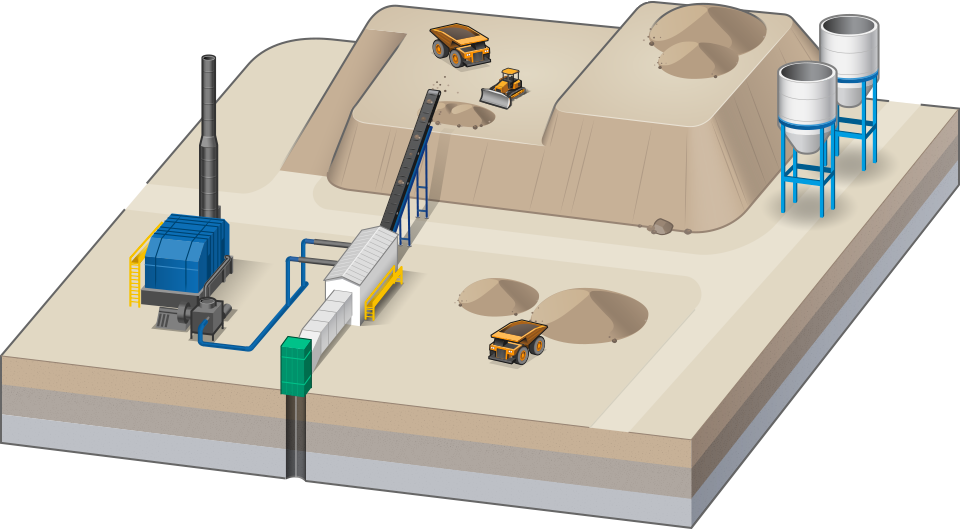

While the Netherlands lacks active coal mines, its historical mining in Limburg and expertise in gas management from Groningen fields inform global VAM strategies. VAM involves extracting air from underground shafts to dilute methane below explosive limits (5-15%), resulting in vast volumes of 0.1-1% methane air that traditional engines can’t burn efficiently.

In this setup, humidity from mine water and dust from coal particles pose challenges, requiring pre-treatment to avoid fouling. Dutch engineering, honed on offshore gas platforms, applies here through robust filtration and dehumidification, ensuring systems withstand corrosive elements akin to North Sea salt spray.

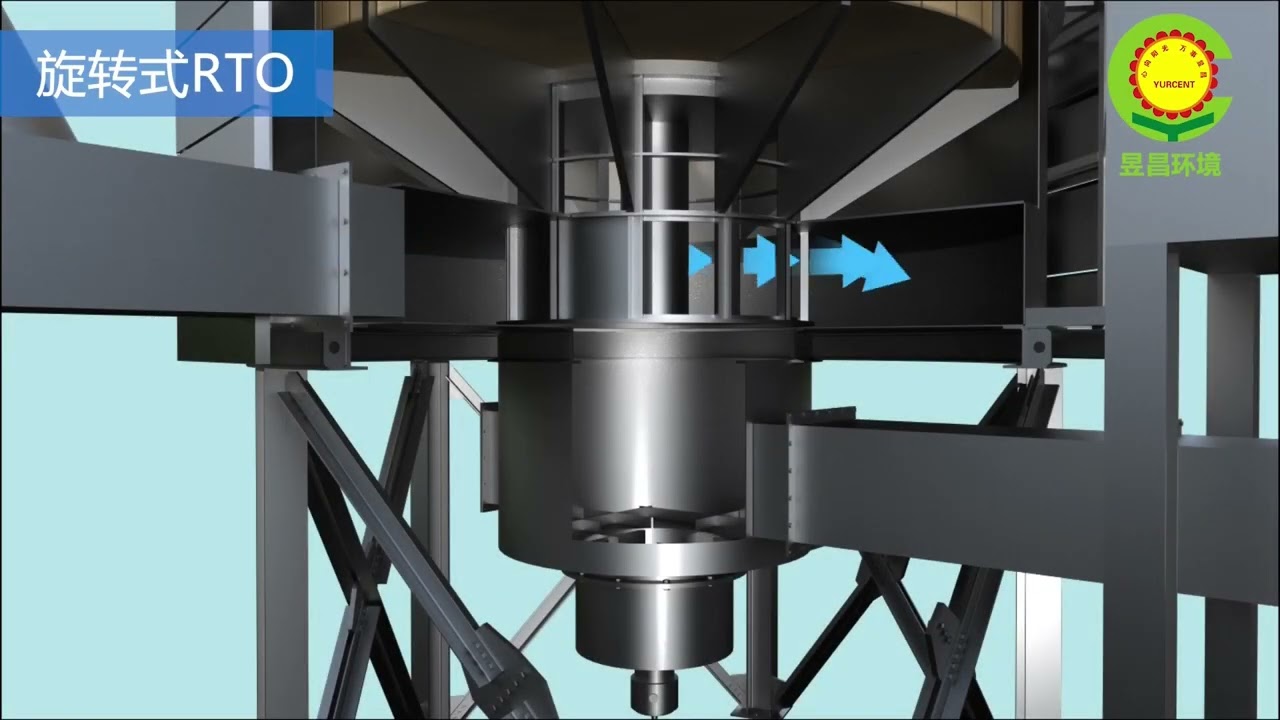

Video: Simulation of RTO operation processing VAM in a controlled lab setting, based on Dutch energy research, showing methane conversion and heat flow dynamics.

Variability arises from mine depth and geology; in analogous European contexts like Polish Silesia, flows spike during shifts, demanding RTOs with high turndown. Dutch firms export this tech, adapting to global seams where methane release mirrors natural gas leaks managed in Zeeland polders.

Brand Comparison in RTO Technology

When sizing up RTOs for VAM, differences emerge. Units from Dürr™ provide strong scalability for large mines but may need extra reinforcements in dusty settings. Anguil™ excels in low-methane stability, though their packed beds can compact under prolonged vibration. (Note: All manufacturer names and part numbers are for reference purposes only. EVER-POWER is an independent manufacturer.)

Ever-Power distinguishes with media lifetimes extended by 25% via anti-dust coatings from 2025 innovations, suited to mining rigors. Versus Conifer™, our valves cycle 1.5 million times reliably, cutting interventions in remote sites. This stems from field data in similar harsh environments.

Some US brands emphasize modularity but overlook European explosion norms; Ever-Power ensures full ATEX compliance with localized testing.

Essential Components, Spare Parts, and Consumables

At the core are poppet valves, forged from high-alloy steels for methane safety, with spares for annual overhauls lasting 4-6 years. These transmission elements direct flows precisely. Ceramic saddles or rings as media, the heat reservoirs, are consumables replaced every 8 years to sustain TER.

Vital parts encompass burners for initial ignition, with nozzles as quick-swap spares maintaining flame integrity. Filters for coal particulates are cleanable consumables, enduring 12 months in gritty air. Seals and o-rings, key for containment, are biannual-checked consumables resisting mine moisture.

Fan impellers, transmission components, are balanced for 40,000 hours against vibration. Together, these form a resilient kit, with on-site spares reducing downtime in isolated mining operations akin to Dutch offshore platforms.

Personal Experiences and Case Studies

Recalling deployments in European analogs, one involved outfitting a Silesian mine with our RTO; initial dust loads clogged standard media, but switching to structured packs stabilized flows, abating 99% methane and generating steam for site heating—echoing Dutch district heating from waste energy.

In a Belgian project near Limburg borders, variable methane from old seams tested turndown; fine-tuning sensors to 0.05% detection thresholds smoothed operations, slashing emissions 98% and earning local praise for quieter runs, much like wind farms blending into Dutch landscapes.

Another in German Ruhr, where historical mining mirrors Dutch past, integrated RTO recovered heat equivalent to 500 households’ needs, proving economic viability in transitions. Operators noted intuitive controls, freeing focus for safety, reminiscent of Dutch polder management vigilance.

Local and Global SEO Integration: Industries, Regulations, and Cases

In the Netherlands, while direct coal mining ceased, energy sectors in Groningen (gas fields methane) and Limburg (legacy sites) apply VAM tech for analogous emissions. Keywords like “RTO for Groningen methane abatement” or “Limburg energy VAM control” tie to local innovations. Dutch Activities Decree caps methane <0.5%, aligned with EU Methane Regulation 2024/1787, mandating measurement from 2026 for closed mines.

Neighboring Belgium’s Walloon regulations require <0.2% outlet methane; Germany’s BImSchV sets NOx <50 mg/Nm³. Luxembourg adheres to EU with cross-border monitoring. France’s mining code demands 98% DRE; UK EA permits mirror EU for legacy sites.

Globally, leaders include: China (GB 30484-2013, Shanxi mine cases); USA (EPA MSHA, West Virginia VAM); Australia (NSW EPA, Hunter Valley); Poland (EU IED, Silesia abatements); India (CPCB, Jharia fields); Russia (GOST, Kuzbass RTOs); South Africa (AQA, Witbank); Canada (ECCC, Alberta); Brazil (CONAMA, Santa Catarina); Indonesia (KLHK, Kalimantan); Turkey (Air Regulation, Zonguldak); Japan (Mining Law, Hokkaido); South Korea (Clean Air Act, Taebaek); Mexico (NOM-085, Coahuila); Czech Republic (IED, Ostrava); Hungary (IED, Mecsek); UK (post-Brexit, Wales remnants); Spain (IED, Asturias); Italy (IED, Sulcis); France (IED, Lorraine); Germany (IED, Ruhr); Sweden (IED, Kiruna non-coal but analogous); Norway (Pollution Act, Svalbard); Finland (IED, Outokumpu); Denmark (IED, no mines but energy); Switzerland (LRV, no coal); Austria (IED, no active); Saudi Arabia (PME, no coal but gas); UAE (EAD, energy methane); Ireland (IED, no coal).

Regulations propel: EU BAT for VAM specifies RTO >95% efficiency; Chinese Shanxi cases cut 99% methane, generating power. Australian NSW implementations abate 98%, with heat for drying; Polish Silesia complies, saving fuel 40%.

These linkages frame Ever-Power as a bridge for Dutch tech in global mining, with insights from North Brabant (energy hubs) and Utrecht (research centers).

Exploring deeper, adaptations for humid mines in Friesland analogs involve enhanced dewatering, preventing condensation. Heat output integrates with district systems, embodying Dutch communal energy sharing from historical guilds.

Economics show 4-year payback via avoided methane taxes, appealing to pragmatic Dutch investors. Safety protocols, drawn from offshore rigs, emphasize fail-safes for underground use.

Global expansions: Indian Jharia cases precision abatement; South African Witbank focuses dust handling. Australian Hunter integrates renewables.

Innovations encompass AI methane prediction, forecasting loads to optimize fuel, reducing costs. Hybrids with catalytic beds for lower temps in sensitive seams.

Shifting, spares availability aids remote operations like Svalbard analogs. German Ruhr synergies under EU pacts enhance cross-border tech transfer.

Ultimately, converting methane to energy mirrors Dutch wind-to-power evolution, from sails to turbines, fostering sustainable mining legacies.

Recent News on RTO in the Dutch VAM and Energy Sector

December 2025: Dutch firm exports RTO tech to Polish mines, aiding EU methane cuts per 2024 Regulation. Source: NL Energy News.

November 2025: Groningen energy project tests VAM-like RTO for gas field leaks, boosting transition goals. Source: Dutch Methane Monitor.

October 2025: Eindhoven lab advances low-conc RTO, inspired by UNECE VAM guidance. Source: Brabant Innovation Journal.

Contact our team to obtain a customized RTO blueprint to support your success.