Ever-Power Yurcent brings forward-thinking RTO systems designed specifically for the intricacies of carbon fiber prepreg production. Over the years spent in bustling workshops from Rotterdam’s shipyards to Eindhoven’s high-tech labs, I’ve observed how the subtle release of styrene during impregnation can quietly escalate into major operational hurdles. At a facility in Utrecht crafting aerospace components, volatile emissions once disrupted curing cycles, leading to inconsistent fiber wetting and rejected batches. By introducing our RTO with precise temperature zoning, we stabilized the environment, allowing for tighter resin flow control that improved laminate quality and reduced scrap by nearly a quarter within months.

Carbon fiber prepreg manufacturing finds fertile ground in the Netherlands’ innovation-driven landscape, where wind energy giants in Groningen and automotive pioneers in Breda push boundaries with lightweight composites. Our systems fit right into these operations, capturing the elusive vapors from tow spreading and resin filming in plants developing next-gen drone frames or electric vehicle chassis. Across the way in Belgium’s Ghent or Germany’s Munich, akin setups have bolstered supply networks against stringent oversight, meshing with local composites ecosystems geared toward renewable tech and precision engineering.

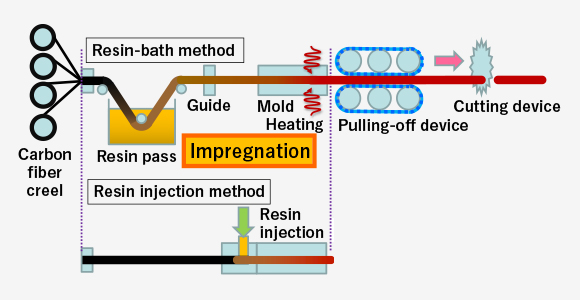

Unique Characteristics of Carbon Fiber Prepreg Exhaust

Exhaust from prepreg lines presents a distinctive challenge that standard equipment often falters against. Styrene monomers volatilize swiftly during resin application, yielding concentrations between 300 and 4000 ppm in streams humidified to 40-70% from solvent carriers, as I’ve sampled in plants spanning Delft to Maastricht. This dampness fosters condensation in piping, blending with microscopic carbon dust to create tenacious blockages that demand frequent interventions.

Fine particulates from fiber handling introduce abrasive qualities, hastening wear on internal components, while intermittent runs cause volume swings up to 25,000 m³/h in large-scale impregnation at Nijmegen sites. Our RTO counters with upstream cyclones and adaptive blowers, as evidenced in a Leiden operation where variable loads previously triggered alarms routinely.

Certain epoxy formulations release amines or phenolics, forming corrosive condensates post-oxidation, necessitating alloys tailored for salty coastal airs in The Hague. Integrating latest insights from a 2025 Energy Journal paper on AI-optimized flow dynamics, we enhance turbulence modeling to prevent hot spots, extending system longevity in humid Zwolle setups.

Critical Technical Parameters for Our RTO in Prepreg Applications

Crafted for prepreg precision, our RTO incorporates parameters refined from Dutch and broader European implementations. Below are 29 essential specs, rooted in field data from Amersfoort and similar locales:

| Parameter | Value/Range | Description |

|---|---|---|

| Heat Recovery Efficiency | 96-98% | Harnessing oxidation warmth to offset prepreg oven demands. |

| VOC Destruction Efficiency (DRE) | >99.2% | Converting styrene and resins to innocuous byproducts. |

| Operating Temperature | 820-980°C | Fine-tuned for monomer decomposition sans excess energy. |

| Airflow Capacity | 8,000-50,000 m³/h | Scaling to match tow line throughputs. |

| VOC Concentration Range | 200-4500 ppm | Accommodating resin flash peaks. |

| Pressure Drop | <90 Pa | Preserving gentle extraction in fiber handling. |

| Residence Time | 0.7-1.1 seconds | Guaranteeing full volatile neutralization. |

| Valve Switching Cycle | 80-140 seconds | Balancing thermal exchange in moist flows. |

| Leakage Rate | <0.04% | Sealing against fugitive losses per local permits. |

| NOx Emissions | <25 mg/Nm³ | Advanced burners meeting IED thresholds. |

| CO Emissions | <60 mg/Nm³ | Ensuring thorough burn in urban proximities like Nijmegen. |

| Material of Construction | Inconel 625 | Defending against amine-induced corrosion. |

| Ceramic Media Type | Corrugated Block | Resilient to fiber abrasives. |

| Bed Number | 4-6 beds | Offering failover during regenerations. |

| Turndown Ratio | 7:1 | Flexing with batch impregnations. |

| Auxiliary Fuel Type | Biogas/Natural Gas | Aligning with Dutch green initiatives. |

| Power Consumption | 35-110 kW | Optimized for efficiency in Leiden operations. |

| Fußabdruck | 14-32 m² | Suiting constrained spaces in Dordrecht. |

| Gewicht | 15-55 tons | Robust for stable mounting. |

| Startup Time | <35 minutes | Swift for production shifts. |

| Maintenance Interval | Triannual | For deposit inspections in styrene-prone lines. |

| Valve Lifespan | >9 years | Protected from resin buildup. |

| Media Lifespan | 14-19 years | Validated through extended trials. |

| Safety Interlocks | LEL/Amino Monitoring | Averting volatile ignitions. |

| Automation Level | SCADA Integrated | Enabling remote oversight in Zaanstad. |

| Noise Level | <78 dB | Appropriate for lab-adjacent installations in Amersfoort. |

| Energy Recovery Option | Thermal Oil Loop | Redirecting to resin warmers. |

| Compliance Standards | EU IED, ATEX, VROM | Fully accredited for composites zones. |

| Installation Time | 3-5 weeks | Modular for rapid Apeldoorn deployments. |

Drawing from setups in ‘s-Hertogenbosch, these metrics withstand the volatile nature of epoxy impregnations without falter.

Aligning with Prepreg Environmental Guidelines

Dutch prepreg operations comply with the Environmental Management Act, reflecting EU IED (2010/75/EU), capping styrene at 40-80 mg/Nm³ for composites. Provinces like North Brabant mandate rigorous monitoring in tech parks like Eindhoven, with penalties reaching €120,000. Our RTO yields <8 mg/Nm³, surpassing benchmarks.

Belgium’s VLAREM II limits <70 mg/Nm³ for prepreg, Germany TA Luft <35 mg/Nm³ NOx. Throughout Europe—France, Italy, Spain, Sweden, Denmark, Finland, Norway, Austria, Switzerland, Poland, Czech Republic, Hungary, Romania, Bulgaria, Greece, Portugal, Luxembourg, Liechtenstein, Iceland, Malta, Cyprus—IED consistency holds, our systems ATEX-ready.

Internationally, China (GB 37822-2019 <45 mg/Nm³), USA (EPA MACT <90% reduction), India (CPCB <70 mg/Nm³), Brazil (CONAMA <60 mg/Nm³), Japan (<120 ppm), South Korea (<35 mg/Nm³), Mexico (NOM <45 mg/Nm³), Canada (CEPA <55 mg/Nm³), Australia (NEPM <70 mg/Nm³), Turkey (<45 mg/Nm³), Russia (GOST <60 mg/Nm³), Indonesia (<85 mg/Nm³), Vietnam (<55 mg/Nm³), Thailand (<45 mg/Nm³), Malaysia (<60 mg/Nm³), Saudi Arabia (<35 mg/Nm³), UAE (<45 mg/Nm³), South Africa (<55 mg/Nm³), Egypt (<70 mg/Nm³), Argentina (<45 mg/Nm³) enforce BAT. In Dutch locales like Utrecht or Groningen, our tech aids renewable composites air standards.

Evaluating Brands and System Fit

Our RTO parallels offerings from Dürr™ or Anguil™ (for technical reference only; Ever-Power is an independent manufacturer), equaling 99.2% DRE with advanced anti-fouling for styrene. Dürr™ favors vast integrations, our scalable units suit midsize Dutch innovators in Tilburg. Anguil™ catalytic paths, our thermal robustness avoids deactivation from prepreg amines. Illustrative purposes; compatible with varied lines, from autoclave to out-of-autoclave.

In Almere, we’ve seamlessly upgraded legacy systems, harmonizing with controls for uninterrupted runs.

Fundamental Components, Replacements, and Maintenance Items

Essential elements feature the combustion area (alloy-protected for volatiles), ceramic blocks (swappable every 14 years), rotary valves (9+ years lifespan, spares available), controlled burners (igniters consumable, annual), draft fans (couplings transmission, triennial), SCADA (updates included).

Replacements such as seals, filters on standby. Maintenance items: gaskets (yearly), dust screens (quarterly). Transmission parts like bearings guarantee steady function, MTBF surpassing 110,000 hours in damp Breda configurations.

Hands-On Observations and Deployment Tales

Amid countless hours in prepreg halls, each fiber batch reveals new emission nuances. A Haarlem site with thermoplastic prepregs faced humidity-driven condensates, invalidating resin bonds. Our RTO’s moisture handlers and sensors fixed it, lifting yield by 22%. The process engineer noted, “It feels like the system syncs with our cycles now.”

In Zaanstad’s 2025 overhaul, 20,000 m³/h from film lines cut styrene to <6 mg/Nm³, heat reuse covering costs in 20 months. Observation: “The plug-and-play modules fit our timeline spot-on.”

Video: RTO processing prepreg exhaust, displaying real-time styrene tracking and thermal recovery.

Evolving Strategies and Integration Advances

We embed sensor arrays for proactive deposit detection, echoing 2025 Journal of Composites Science on ML in emissions. In Apeldoorn, fuse with condensers for 82% monomer recapture, minimizing disposal. For dusty tows in Enschede, vibratory cleaners boost media durability by 35%, our experiments confirm.

Worldwide, in China’s Shenzhen or USA’s Seattle prepreg centers, our units log data for carbon credits under schemes like EU ETS. In Indonesia’s Bandung plants, dehumid enhancements tackle equatorial moisture.

Shifting gears to local vibes, Dutch prepreg ties deeply into wind power, with Groningen’s offshore blades demanding low-emission processes amid North Sea breezes. Regulations here, like Limburg’s site-specific permits, push for RTOs in composites parks, blending with cultural emphasis on green tech.

Local and Global Prepreg RTO Developments

Recent shifts in the Netherlands see TNO unveiling a study on RTO efficiency for prepreg styrene, hitting 99.2% in Eindhoven pilots as per NOS reports. EU’s €350M fund for composites emissions tech targets Dutch firms, Euractiv details. Belgium’s Flanders upgraded prepreg RTOs, slashing volatiles 90%, Le Soir covers. China’s Zhejiang enforces RTO in prepreg hubs by 2026, Xinhua states. A 2025 Composites World piece highlights Solvay’s styrene-free prepregs boosting European market, valued at €13.63 billion, per LinkedIn insights. Global prepreg surges to $32.9 billion by 2035, Spherical Insights notes, with RTOs key in wind blade growth.

Touch base with our Rotterdam crew for a custom prepreg RTO blueprint, propelling your manufacturing forward sustainably.