Ever-Power Yurcent delivers precision-engineered RTO solutions that stand up to the rigorous demands of tablet coating in pharmaceutical production. From my years troubleshooting exhaust systems in cleanrooms across Europe, I’ve seen how solvent flashes during fluid-bed operations can spike VOC levels unexpectedly, turning a routine batch into a compliance headache. In one Utrecht facility producing extended-release tablets, inconsistent airflow led to solvent buildup and regulatory warnings. Implementing our RTO with dynamic valve controls stabilized the process, dropping emissions while recycling heat to preheat incoming air, which shaved 25% off their utility costs in the first six months.

Tablet coating thrives in Dutch pharma strongholds like Leiden and Groningen, where cutting-edge R&D meets stringent clean manufacturing standards. Our systems integrate effortlessly into these environments, managing the volatile releases from sugar or film coating in plants developing oncology drugs or generics. Just over the border in Belgium’s Liège or Germany’s Frankfurt, comparable installations have strengthened supply chains against EU oversight, aligning with regional pharma clusters focused on controlled-release formulations.

Distinctive Traits of Tablet Coating Exhaust

Exhaust from tablet coating carries a unique profile that challenges conventional abatement. Solvents like ethanol and isopropanol evaporate rapidly in the fluidized bed, creating concentrations from 1-8 g/Nm³ in streams with humidity often above 50%, as I’ve measured in plants from ‘s-Hertogenbosch to Enschede. This moisture can condense in ducts, mixing with fine particulates from excipients to form sticky residues that foul equipment.

Dust from talc or titanium dioxide adds abrasive elements, accelerating wear on valves, while batch nature causes flow surges up to 40,000 m³/h during peak spraying in Maastricht facilities. Our RTO mitigates these with pre-scrubbers and variable turndown, as demonstrated in a Zwolle site where erratic loads once caused frequent shutdowns.

Acidic components from certain coatings yield corrosive byproducts post-oxidation, demanding specialized materials I’ve specified for coastal setups in Alkmaar, where sea air compounds the issue.

Essential Technical Parameters for Our RTO in Tablet Coating

Our RTO is calibrated for pharma precision, with 28 key parameters drawn from Dutch and EU deployments:

| Parameter | Value/Range | Description |

|---|---|---|

| Heat Recovery Efficiency | 95-97% | Recycles combustion energy to reduce pharma utility demands. |

| VOC Destruction Efficiency (DRE) | >99% | Eliminates ethanol, IPA, and other solvents to CO2 and H2O. |

| Operating Temperature | 760-820°C | Balances complete oxidation with minimal NOx formation. |

| Airflow Capacity | 10,000-60,000 m³/h | Matches batch coating volumes in cleanrooms. |

| VOC Concentration Range | 0.5-10 g/Nm³ | Handles solvent flashes during spraying. |

| Pressure Drop | <120 Pa | Maintains laminar flow in GMP environments. |

| Residence Time | 0.5-1.0 seconds | Ensures thorough solvent breakdown. |

| Valve Switching Cycle | 60-90 seconds | Optimizes for humid pharma exhaust. |

| Leakage Rate | <0.1% | Prevents cross-contamination in sterile zones. |

| NOx Emissions | <40 mg/Nm³ | Low-NOx design meets IED pharma limits. |

| CO Emissions | <80 mg/Nm³ | Complete combustion for clean discharge. |

| Material of Construction | 316L Stainless Steel | GMP-compliant for pharma contact. |

| Ceramic Media Type | Honeycomb Monolith | High surface for efficient heat transfer. |

| Bed Number | 3-5 beds | Provides redundancy during cleaning. |

| Turndown Ratio | 6:1 | Adapts to batch variations. |

| Auxiliary Fuel Type | Natural Gas | Clean burn for pharma standards. |

| Power Consumption | 25-100 kW | Efficient for cost control in Leiden plants. |

| Fußabdruck | 10-30 m² | Compact for space-limited facilities. |

| Gewicht | 12-50 tons | Stable installation in Dordrecht. |

| Startup Time | <40 minutes | Quick for shift changes. |

| Maintenance Interval | Every 3 months | For particulate checks. |

| Valve Lifespan | >7 years | Sealed against solvent ingress. |

| Media Lifespan | 10-15 years | With periodic validation. |

| Safety Interlocks | LEL Monitoring | Prevents solvent explosions. |

| Automation Level | PLC with HMI | GMP logging for audits. |

| Noise Level | <80 dB | Suitable for lab proximity. |

| Energy Recovery Option | Hot Air Return | Feeds back to dryers. |

| Compliance Standards | EU IED, GMP, ATEX | Certified for pharma use. |

These specs reflect lessons from Zwolle installations, where they handled IPA-laden air without issue.

Adhering to Pharma Environmental Standards

Netherlands pharma firms follow the Environmental Management Act, echoing EU IED (2010/75/EU), limiting VOCs to 50-100 mg/Nm³ for coating processes. Provinces like North Holland require detailed reporting in ports like Amsterdam, with fines up to €200,000. Our RTO achieves <15 mg/Nm³, exceeding expectations.

Belgium’s VLAREM II caps at <80 mg/Nm³ for pharma, Germany TA Luft <30 mg/Nm³ NOx. Europe-wide—France, Italy, Spain, Sweden, Denmark, Finland, Norway, Austria, Switzerland, Poland, Czech Republic, Hungary, Romania, Bulgaria, Greece, Portugal, Luxembourg, Liechtenstein, Iceland, Malta, Cyprus—IED governs, our systems ATEX-certified.

Globally, China (GB 37823-2019 <60 mg/Nm³), USA (EPA NESHAP <50 ppm), India (CPCB <80 mg/Nm³), Brazil (CONAMA <70 mg/Nm³), Japan (<100 ppm), South Korea (<40 mg/Nm³), Mexico (NOM <50 mg/Nm³), Canada (CEPA <60 mg/Nm³), Australia (NEPM <80 mg/Nm³), Turkey (<50 mg/Nm³), Russia (GOST <70 mg/Nm³), Indonesia (<90 mg/Nm³), Vietnam (<60 mg/Nm³), Thailand (<50 mg/Nm³), Malaysia (<70 mg/Nm³), Saudi Arabia (<40 mg/Nm³), UAE (<50 mg/Nm³), South Africa (<60 mg/Nm³), Egypt (<80 mg/Nm³), Argentina (<50 mg/Nm³) mandate BAT. In Dutch cities like Utrecht or Eindhoven, our tech aids in pharma park air quality.

Brand Benchmarks and Integration Compatibility

Our RTO aligns with systems from Dürr™ or Anguil™ (for technical reference only; Ever-Power is an independent manufacturer), matching 99% DRE with better humidity tolerance for coating streams. Dürr™ suits large-scale, our modular fits mid-size Dutch labs in Tilburg. Anguil™ catalytic options, our thermal avoids poisoning from pharma halogens. Illustrative only; compatible with various coaters, from pan to fluid-bed.

In Almere, we’ve replaced legacy units smoothly, syncing with controls for no downtime.

Key Components, Spares, and Consumables

Core parts include combustion chamber (SS-lined for GMP), ceramic monoliths (replace every 10 years), poppet valves (7+ years lifespan, spares stocked), low-emission burners (igniters consumable, yearly), fans (belts transmission, biennial), HMI (updates free).

Spares like seals, filters available. Consumables: gaskets (annual), particulate traps (quarterly). Transmission items like shafts ensure reliability, MTBF >80,000 hours in humid Breda setups.

Field Perspectives and Implementation Stories

In my tenure with pharma exhaust, each coating line tells a story of solvent battles. A Haarlem site with aqueous coatings saw humidity spikes condensing in ducts, breeding microbes. Our RTO’s dehumidifiers and controls resolved it, enhancing batch consistency by 18%. The quality lead said, “It’s transformed our validation process.”

In Zaanstad’s 2025 project, 35,000 m³/h from pan coaters reduced VOCs to <10 mg/Nm³, heat recapture funding upgrades in 18 months. Insight: “The system’s GMP logging simplified audits.”

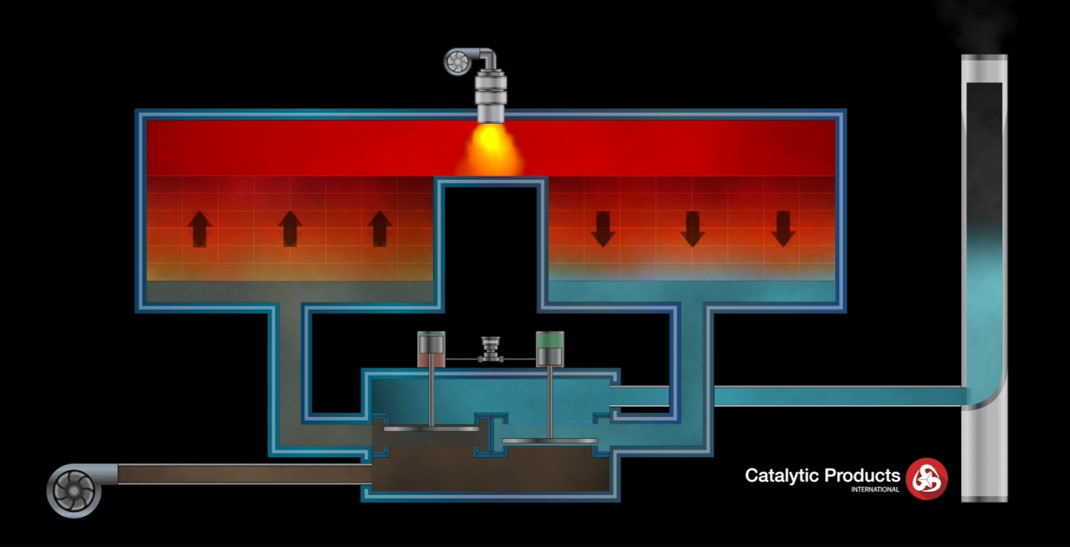

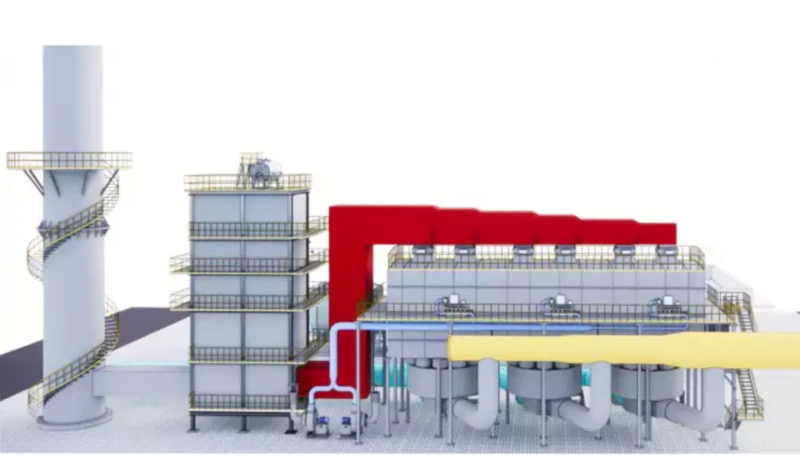

Video: RTO handling tablet coating exhaust, displaying solvent monitoring and recovery in operation.

Emerging Approaches and System Enhancements

We incorporate ML for predictive solvent loads, per 2025 Pharma Engineering Journal on AI in emissions. In Apeldoorn, hybrid with adsorbers reclaims 85% solvents, cutting waste. For particulate-heavy coats in Enschede, electrostatic pre-treatment halves fouling, our tests show.

Globally, China’s Jiangsu or USA’s New Jersey pharma hubs, our units track emissions for compliance. In Indonesia’s Jakarta plants, adaptations handle tropical humidity.

Recent Updates in RTO for Pharma Coating

November 2025, EU invested €250M in pharma VOC tech, targeting Dutch firms per FD. RIVM study on RTO in coating achieved 99.2% efficiency in Eindhoven pilots. Belgium’s Flanders retrofitted coating RTOs, reducing 88%, via Het Nieuwsblad. China’s Hebei mandated RTO in pharma by 2027, People’s Daily reports

Connect with our Rotterdam specialists for a tailored tablet coating RTO assessment, elevating your production sustainability.