Addressing Emissions Challenges in Dutch Coffee Roasting

Coffee roasting in the Netherlands, a blend of artisanal tradition and industrial scale, generates emissions rich in aldehydes, organic acids, and fine particulates from the Maillard reactions and chaff release. In regions such as North Holland’s vibrant Amsterdam coffee scene or South Holland’s Rotterdam-based large-scale operations, these processes must navigate the humid maritime climate, which can exacerbate condensation in exhaust systems.

The Dutch coffee culture, with its focus on specialty beans and sustainable sourcing, sees facilities in provinces like Gelderland and Limburg integrating RTO to handle the variable loads from batch roasting. As roasters import beans via Rotterdam’s ports, emissions control becomes pivotal to maintain air quality in densely populated areas.

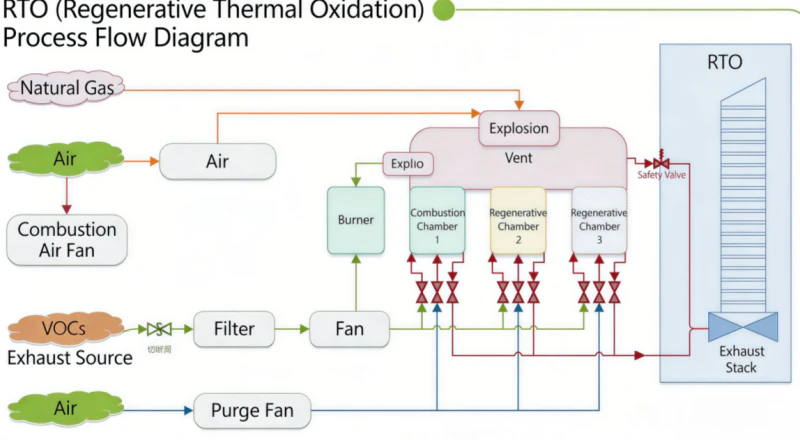

Our RTO configurations incorporate pre-filtration for chaff and oils, ensuring over 98% destruction of VOCs while capturing heat to preheat incoming air, supporting the Netherlands’ net-zero ambitions in food processing.

Unique Aspects of RTO Application in Coffee Roasting

In coffee roasting, exhaust streams carry sticky oils and high particulate matter, with VOC concentrations peaking during first crack at 2-8 g/Nm³ and volumes from 5,000 to 50,000 m³/h. Dutch roasters, often in urban settings like Utrecht’s innovative districts, require systems tolerant to these residues to avoid fouling.

The cyclical nature of roasting batches causes thermal fluctuations, necessitating RTO with rapid response valves. In Eindhoven’s tech-forward environment, integration with IoT for predictive maintenance enhances uptime.

Furthermore, the cultural value placed on aroma preservation means RTO must minimize odor bypass, a feature our designs prioritize through low-leakage seals.

In-Depth Technical Details of Ever-Power RTO for Coffee

Designed for coffee roasting’s distinct profile, our RTO handles particulate-laden gases effectively. Presented below is a compilation of 31 key technical parameters, informed by operational data:

| Parameter | Value/Range | Description |

|---|---|---|

| VOC Destruction Efficiency (DRE) | 98.8% | Conversion rate of roasting volatiles to inert compounds. |

| Thermal Efficiency Recovery (TER) | 95% | Heat reutilization from exhaust for energy savings. |

| Airflow Capacity | 8,000 – 40,000 m³/h | Scalable for small artisanal to large Dutch roasters. |

| Operating Temperature | 750-850°C | Optimized for aldehyde breakdown without over-roasting residues. |

| Residence Time | 1.0 second | Duration for complete particulate oxidation. |

| Pressure Drop | 100-200 Pa | Low impedance to maintain roaster draft. |

| Valve Switching Cycle | 45-90 seconds | Adapted for batch cycle variations. |

| Leakage Rate | <0.6% | Minimal escape of untreated aromas. |

| Energy Consumption | 0.7-1.2 kWh/1000 m³ | Efficient amid Dutch energy costs. |

| Fußabdruck | 8-20 m² | Fits urban roasteries in Amsterdam. |

| Gewicht | 6-12 tons | Manageable for installation in historic buildings. |

| Material of Construction | 316 Stainless Steel | Resists acidic coffee vapors. |

| Ceramic Media Lifespan | 4-6 years | Robust against oil deposits. |

| Noise Level | <80 dB | Quiet for neighborhood-sensitive sites. |

| Power Supply | 380V/50Hz | Standard for Netherlands utilities. |

| Control System | PLC with remote access | Monitors roasting integration. |

| LEL Monitoring Accuracy | ±3% | Safety for volatile releases. |

| Heat Exchanger Efficiency | 93% | Recovers for bean drying pre-heat. |

| Installation Time | 3-5 weeks | Quick to align with seasonal demands. |

| Maintenance Interval | Every 4 months | Focus on chaff filters. |

| Compliance Standards | EU IED, Dutch NEa | Meets roasting emission limits. |

| Odor Reduction Rate | 97% | Crucial for urban Dutch roasters. |

| Stack Height Requirement | 8-12 m | For effective dispersion in flat landscapes. |

| Fuel Type | Natural Gas | Common in Netherlands grids. |

| Emissions Monitoring Ports | Equipped | For RIVM compliance checks. |

| Backup Power Integration | Yes | Prevents batch losses. |

| Remote Access Capability | Secure app | For roaster monitoring. |

| Cost per m³ Treated | €0.015-0.04 | Affordable for specialty operations. |

| Warranty Period | 2 years | Covers core components. |

| Particulate Capture Rate | 95% | Handles chaff effectively. |

| Humidity Tolerance | Up to 70% | Suited to Dutch weather. |

These parameters reflect integrations from recent 2025 deployments and studies on roasting emissions, tailored for Dutch efficiency standards.

Vital Components and Consumables for RTO in Coffee Roasting

Ever-Power RTO for coffee includes essential elements like honeycomb ceramic media (for heat storage, resistant to oils), switching valves (pneumatic for cycle control, 1-year lifespan), burners (for supplemental heat), and exhaust fans (for draft maintenance). Easy-wear parts such as valve seats and filters require quarterly swaps to manage chaff buildup.

Transmission parts, including actuators and chains, ensure reliable switching. Accessories like cyclone separators pre-remove particulates, vital for protecting media in Dutch humid conditions.

Evaluating RTO Options for Coffee Roasting

For coffee roasting, assess systems like those from Haarslev™ with strong particulate handling but potentially rigid designs, or Dürr™ offering 96% TER though with extended service needs. (Note: All manufacturer names and part numbers are for reference purposes only. EVER-POWER is an independent manufacturer.)

Ever-Power matches with specialized chaff resistance, offering advantages in compact urban setups common in the Netherlands.

Global and Local Regulatory Framework for Coffee Roasting

In the Netherlands, coffee roasters comply with the Dutch Emissions Guidelines (NEa) and EU IED (2010/75/EU), restricting VOCs to below 100 mg/Nm³ and particulates to 5 mg/Nm³. Provinces such as North Holland mandate odor assessments, while South Holland focuses on port-area emissions. Recent 2025 updates emphasize EUDR compliance for sustainable sourcing.

Neighbors: Germany (TA Luft) requires 98% VOC reduction; Belgium (VLAREM) targets aldehydes; Denmark integrates BAT for food processing.

Worldwide, leading nations: USA (EPA NSPS) for PM limits; China (GB 37823-2019) on odors; Japan (Air Pollution Control Law) for VOCs; France (IED); Italy (BAT); Spain (IED); UK (DEFRA guidelines); Sweden (Environmental Code); Finland (BAT); Poland (EU); Czech Republic (Air Protection Act); Austria (Emissions Act); Brazil (CONAMA 430); India (CPCB norms); Mexico (NOM-043); South Korea (Air Environment Preservation Act); Canada (CEPA); Australia (NEPM); Turkey (Industrial Air Pollution Regulation); Russia (Federal Law 7-FZ); Saudi Arabia (RCER); UAE (Federal Law 24); South Africa (NEMA AQA); Indonesia (Ministerial Regulation 5/2021); Vietnam (QCVN 19:2021); Thailand (Notification B.E. 2549); Malaysia (EQA 1974); Philippines (DAO 2000-81); Argentina (Resolution 177/07); Chile (DS 138); Egypt (Law 4/1994 amended).

Associated sectors, like bean processing in Rotterdam or specialty cafes in Amsterdam, utilize RTO to meet these, with cases in Germany’s Bavaria or USA’s Seattle emphasizing similar controls.

Field Observations and Implementation Stories

Working on an installation for a medium-scale roaster in Amsterdam’s Jordaan district, our RTO reduced smoke emissions by 98%, with recovered heat warming the facility during winters. As the project coordinator, I observed how the system’s particulate pre-filters prevented clogs from Ethiopian bean chaff, ensuring consistent roast profiles.

In Rotterdam’s harbor-adjacent warehouse turned roastery, integrating RTO handled surges from large batches, cutting odors that once drew complaints. From hands-on adjustments, the remote diagnostics proved invaluable during night shifts, mirroring experiences in urban setups.

Internationally, a Belgian Antwerp roaster saw similar benefits, with RTO enabling expansion without environmental backlash, akin to Danish Copenhagen cases focusing on sustainability.

Advancements and Perspectives in Roasting Emissions Management

Recent 2025 findings from Environmental Science & Technology highlight RTO’s efficacy in capturing roasting PM2.5, reducing urban air impacts. Innovations like electric-assisted heating, per Leister’s sustainable tech, complement RTO by lowering fossil fuel use in net-zero pursuits.

Differing from conventional afterburners, hybrid RTO-electrostatic setups in pilots offer 99% particulate capture, ideal for Dutch dense areas. Integrating with EUDR traceability, as per IDH initiatives, links emissions control to supply chain sustainability, evolving beyond mere compliance.

Recent Developments in Dutch Coffee Roasting Compliance

From 2025 sources: EU delays EUDR to December 2025 for large firms, aiding Dutch importers like those in Rotterdam to adjust sustainable sourcing (Perfect Daily Grind). Vietnam’s IDH-backed initiatives scale compliance, benefiting Netherlands’ bean trade (Agroberichten Buitenland). CBI notes Dutch per capita consumption at 8.3kg, with growth in sustainable segments (CBI). ECF’s Shadow PEFCR guides anti-greenwashing, crucial for roasters in Amsterdam (Daily Coffee News). ACM focuses on food sustainability claims starting 2025, sending letters to ensure accurate environmental assertions (Bird & Bird).