Este artículo ofrece un análisis exhaustivo del valor ambiental y los beneficios sociales de la tecnología de oxidación térmica regenerativa (RTO) en los Países Bajos y la Unión Europea. Según datos del Instituto Neerlandés de Medio Ambiente e Infraestructura (RIVM) y la Agencia Europea de Medio Ambiente (AEMA), un sistema de RTO de tamaño mediano (100.000 m³/hora) que funciona durante 8.000 horas al año puede lograr importantes beneficios ambientales: reducir las emisiones de COV entre 200 y 500 toneladas al año, equivalente a las emisiones anuales de entre 5 y 10 plantas químicas pequeñas y medianas en la zona portuaria de Róterdam; reducir las emisiones de CO₂ equivalentes entre 4.800 y 12.000 toneladas al año, equivalente a las emisiones anuales de entre 1.200 y 3.000 camiones diésel; y recuperar entre 5,6 y 14 GWh anuales de energía térmica, lo que puede proporcionar calefacción anual a entre 1.000 y 2.500 hogares neerlandeses.

1. ¿Qué es la oxidación térmica regenerativa (RTO)?

El Oxidador Térmico Regenerativo (RTO) es un sistema de tratamiento de gases residuales orgánicos altamente eficiente, diseñado específicamente para tratar compuestos orgánicos volátiles (COV) y contaminantes atmosféricos nocivos (HAP) de baja a media concentración y alto volumen. Convierte los componentes orgánicos en dióxido de carbono y vapor de agua mediante oxidación a alta temperatura (normalmente de 760 °C a 1200 °C), a la vez que recupera energía térmica mediante regeneradores cerámicos, alcanzando una eficiencia térmica superior a 951 TP3T y reduciendo significativamente el consumo energético operativo.

Ventajas clave:

- Alta eficiencia de recuperación de calor (hasta 97%)

- Alta tasa de eliminación de COV (95%-99%)

- Adecuado para diversas industrias y composiciones complejas de gases residuales.

- Beneficios económicos significativos en la operación a largo plazo

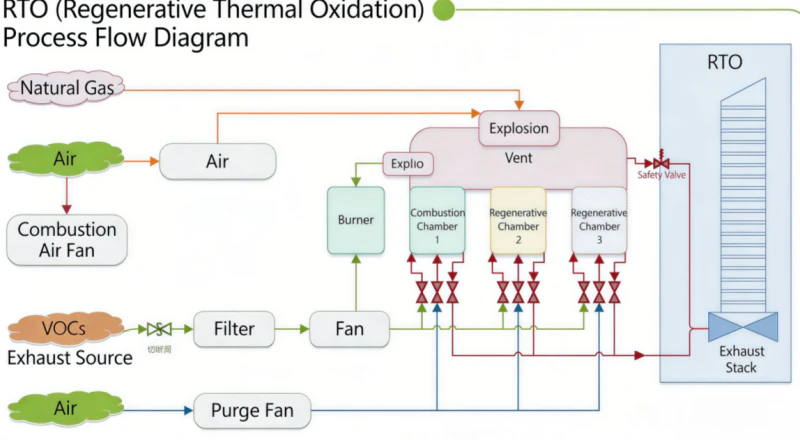

2. Principio de funcionamiento de la tecnología RTO

Un sistema RTO típico contiene tres o más regeneradores cerámicos, con un ciclo de trabajo dividido en cinco etapas clave:

Etapa 1: Precalentamiento del aire de admisión

El gas de escape ingresa al primer regenerador a través de la válvula de admisión, fluye a través del regenerador cerámico de alta temperatura (la temperatura normalmente es superior a 800 °C) y se precalienta hasta cerca de la temperatura de oxidación.

Etapa 2: Descomposición oxidativa

Los gases de escape precalentados entran en la cámara de combustión. Con el mantenimiento del combustible auxiliar (gas natural), la temperatura se eleva hasta la temperatura de oxidación establecida (normalmente entre 760 y 850 °C), y las moléculas orgánicas experimentan una reacción de oxidación:

CxHy + (x+y/4)O₂ → xCO₂ + (y/2)H₂O + calor

Etapa tres: almacenamiento de calor

El gas purificado a alta temperatura ingresa al segundo regenerador, transfiere calor al regenerador cerámico y reduce su propia temperatura hasta cerca de la temperatura de entrada.

Etapa 4: Cambio de válvulas

El sistema de control inteligente cambia la dirección del flujo de aire regularmente (generalmente cada 60 a 120 segundos) para garantizar una eficiencia de procesamiento continua.

Etapa 5: Ciclo de purga

El tercer regenerador se purga para evitar la emisión directa de gases residuales sin tratar y garantizar una tasa de eliminación estable.

3. Tipos principales de sistemas RTO

<<<<

| Tipo</ | Condiciones Aplicables</ | Rango de concentración de COV | Eficiencia de eliminación | Costo de inversión</ |

|---|---|---|---|---|

| RTO de dos torres | Volumen de aire medio-pequeño, producción continua | 1,5-10 g/m³ | 95-98% | Medio |

| RTO de tres torres | Gran volumen de aire, continuo/intermitente | 0,5-15 g/m³ | 98-99.5% | Alto |

| RTO rotatorio | Volumen de aire extra grande, espacio limitado | 0,5-12 g/m³ | 95-99% | Medio-alto |

| Rotor de zeolita + RTO | Concentración ultrabaja, gran volumen de aire | 0,1-2 g/m³ | 90-98% | Alto |

4. Práctica de aplicación de la tecnología RTO en industrias clave

4.1 Industria química y farmacéutica

- Características de los gases de escape: composición compleja, conteniendo halógenos, sulfuros, etc.

- Solución: añadir un depurador de pretratamiento y utilizar materiales cerámicos resistentes a la corrosión.

- Datos del caso: Después de que una empresa farmacéutica instaló un RTO de tres torres, procesó 220 millones de metros cúbicos de gas residual al año, con una tasa de eliminación de COV de 99,2% y una reducción anual de emisiones de 385 toneladas.

4.2 Industria de impresión y recubrimiento

- Características de los gases de escape: gran volumen de aire, baja concentración, contiene partículas.

- Solución: Configurar el pretratamiento de filtración en seco para optimizar la distribución de la entrada de aire

- Análisis económico: Una determinada línea de pintura de automóviles utiliza un RTO rotatorio con una eficiencia de recuperación de calor de 96%, ahorrando alrededor de 1,8 millones de yuanes en costos de gas natural al año.

4.3 Industria de fabricación de productos electrónicos

- Desafío especial: Los compuestos que contienen silicio pueden provocar obstrucciones en la cerámica.

- Mejoras técnicas: desarrollo de programas de limpieza especiales y sistemas de aditivos

4.4 Industria de procesamiento de alimentos

- Características de los gases de escape: alta humedad, conteniendo partículas de grasa.

- Plan de tratamiento: proceso combinado de filtración multicapa + ajuste de humedad + RTO

5. Comparación entre RTO y otras tecnologías de tratamiento de COV

| Parámetros técnicos | RTO | Oxidación catalítica (CO) | Adsorción de carbón activado | Tratamiento biológico |

|---|---|---|---|---|

| Concentración aplicable | Medio-bajo (1-15 g/m³) | Medio-Bajo (1-10g/m³) | Bajo (<1 g/m³) | Muy bajo (<0,5 g/m³) |

| Eficiencia del tratamiento | 95-99.5% | 90-98% | 70-95% | 70-90% |

| Costo de operación | Medio | Medio-bajo | Alto (reemplazo de carbono) | Bajo |

| Contaminación secundaria | Ninguno | Reemplazo del catalizador | Carbono de residuos peligrosos | Tratamiento de lodos |

| Consumo de energía | Bajo (después de la recuperación de calor) | Medio | Bajo | Muy bajo |

El precio del RTO rotativo EVER-POWER es de solo 35–40% de las marcas europeas y ofrece un rendimiento idéntico o mejor y una garantía de 5 años.

Reemplazamos una unidad Dürr de 15 años en Amberes por un RTO rotativo EVER-POWER. Ocupa el mismo espacio, se puso en marcha en 3 días y la factura de energía se redujo en 41%. La mejor decisión. — Jan De Vries, Gerente de Planta, BASF Amberes, Bélgica

La nueva ley ambiental brasileña exige la eliminación de 99%. La unidad EVER-POWER alcanzó 99,7% en una prueba independiente, con un periodo de recuperación de 11 meses. — Carlos Silva, planta de recubrimiento de São Paulo

6. Valor de protección ambiental y beneficios sociales del sistema RTO

6.1 Análisis cuantitativo de la contribución a la reducción de emisiones

Según las estadísticas de la Asociación de la Industria de Protección Ambiental de China, un sistema RTO de tamaño mediano (100.000 m³/h) puede funcionar durante 8.000 horas al año:

- Reducir las emisiones de COV: 200-500 toneladas/año

- Reducir las emisiones de CO₂ equivalente: equivalente a plantar 12.000 árboles

- Recuperación de calor: equivalente a ahorrar 800 toneladas de carbón estándar al año

6.2 Cumplir con los estándares ambientales globales

- China: “Ley de Prevención y Control de la Contaminación Atmosférica”, “Normas de Control de Emisiones de Compuestos Orgánicos Volátiles No Organizados”

- UE: Directiva IED (Directiva sobre emisiones industriales), Documento de conclusiones sobre las MTD

- Estados Unidos: Normas NESHAP de la EPA, Ley de Aire Limpio

Preguntas frecuentes

1. ¿Qué subvenciones gubernamentales puedo obtener por invertir en un sistema RTO en los Países Bajos?

El gobierno neerlandés ofrece diversos incentivos financieros: la Deducción por Inversión Ambiental (MIA) puede suponer una deducción fiscal de hasta 361 TP3T del importe de la inversión; la Depreciación Aleatoria (Vamil) ofrece un plan de depreciación flexible; y el Subsidio a la Inversión Energética (EIA) ofrece una deducción adicional de 13,51 TP3T. Las empresas también pueden solicitar financiación del programa LIFE de la UE y subvenciones para el desarrollo sostenible de los gobiernos locales.

2. ¿El sistema RTO cumple con los requisitos de la UE BAT (Mejor tecnología disponible)?

Sí. La tecnología RTO se ha incluido en el BREF (Documento de Referencia de la Mejor Tecnología Disponible) de la UE como tecnología recomendada para el tratamiento de COV. Cumple plenamente con los requisitos de la Directiva de Emisiones Industriales (DEI). Su eficiencia de eliminación suele alcanzar entre 95% y 99,5%, cumpliendo así con los estándares mínimos de emisiones.

3. ¿Qué requisitos específicos establece la Ley de Clima holandesa para las solicitudes de RTO?

De acuerdo con el objetivo de reducción de emisiones de 49% para 2030 de la Ley del Clima de los Países Bajos, el sector industrial necesita reducir significativamente sus emisiones. El sistema RTO contribuye directamente a la reducción de la huella de carbono de la empresa mediante la recuperación eficiente de calor (hasta 97%) y la reducción de las emisiones de COV, y apoya la implementación de la hoja de ruta nacional para la neutralidad de carbono.

4. ¿A qué debemos prestar atención cuando tratamos con gases residuales que contienen componentes especiales (como halógenos y compuestos de silicio)?

La oxidación de materia orgánica que contiene cloro o flúor puede producir dioxinas y gases ácidos. Se recomienda: 1) aumentar la temperatura de oxidación por encima de 1000 °C; 2) añadir una torre de enfriamiento y un postratamiento de lavado alcalino; 3) seleccionar cerámicas especiales resistentes a la corrosión. Los compuestos que contienen silicio requieren filtración previa al tratamiento y procedimientos de limpieza regulares.

5. ¿Cómo evaluar el ciclo de retorno de la inversión específico del sistema RTO en los Países Bajos?

La inversión en un sistema RTO típico de tamaño mediano es de entre 800.000 y 1,5 millones de euros. El periodo de amortización es de 4 a 6 años sin subvenciones; puede acortarse a 2,5-4 años utilizando el paquete de subvenciones neerlandés. Factores clave: concentración de COV, precios de la energía, horas de funcionamiento, eficiencia de la recuperación de calor e ingresos por comercio de carbono.

6. ¿Cómo se integra el sistema RTO con el modelo de “simbiosis industrial” holandés?

La energía térmica recuperada por el RTO (5,6-14 GWh/año) puede incorporarse a la red de calefacción urbana (Warmtenet) para su uso por parte de empresas o zonas residenciales cercanas. El modelo de "Procesamiento como Servicio" del Puerto de Róterdam permite a las pequeñas y medianas empresas compartir las instalaciones del RTO y reducir los costes de inversión de cada empresa.

7. ¿Qué mantenimiento periódico requiere el sistema RTO en los Países Bajos?

Mensualmente: inspección del quemador, lubricación de válvulas.

Trimestral: Monitoreo del diferencial de presión del regenerador cerámico

Medio año: Calibración de termopares, actualización del sistema de control

Anual: Informes completos de pruebas de rendimiento y pruebas de cumplimiento

Cada 3-5 años: Pruebas de muestreo de materiales cerámicos

8. ¿Cómo garantizar que el sistema RTO cumpla con los estrictos estándares de seguridad de los Países Bajos?

Debe estar equipado con: 1) Monitoreo en línea de la concentración de LEL y sistema automático de dilución; 2) Puerta antideflagrante y dispositivo de ventilación (certificación ATEX); 3) Triple monitoreo de llama y protección contra apagado de llama; 4) Control de interbloqueo de seguridad con el sistema de producción. Se debe seguir la guía PGS-33.

9. ¿Cómo elegir entre RTO y RCO (oxidación catalítica regenerativa) en los Países Bajos?

El RCO tiene una temperatura de funcionamiento baja (300-500 °C) y es adecuado para gases de escape que no contienen venenos para el catalizador (como disolventes). El RTO tiene una temperatura más alta (760-850 °C), una aplicabilidad más amplia, pero un mayor consumo de energía. La selección se basa en la composición de los gases de escape, las fluctuaciones de concentración, el coste de la vida útil del catalizador y la sensibilidad a la temperatura.

10. ¿Cómo apoya el sistema RTO la transición al hidrógeno y la electrificación de los Países Bajos?

Adaptación de la energía del hidrógeno: el quemador se puede modificar para utilizar hidrógeno verde como combustible auxiliar

Camino de electrificación: desarrollo de RTO calentados eléctricamente y utilización de energía eólica marina holandesa

Integración de la red: participe en la respuesta de la demanda de TenNET para lograr una operación flexible

Preparación futura: Interfaz de reserva para la captura de carbono (CCUS) para apoyar la descarbonización a largo plazo

Para obtener más información, visite nuestro página principal