VOCs Treatment

Comprehensive VOCs Treatment Solution – RTO (Regenerative Thermal Oxidation) Technology

What are VOCs?

Volatile Organic Compounds (VOCs) are organic chemicals with high vapor pressure (≥0.01 kPa at 25℃) at room temperature, easily evaporating from solid or liquid forms. They exhibit strong volatility and chemical reactivity, serving as key precursors to air pollutants and photochemical smog (e.g., ozone, PAN – Peroxyacetyl Nitrate).

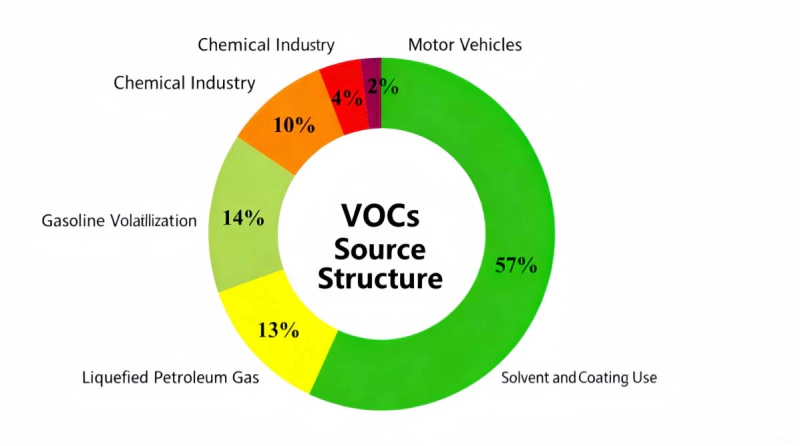

Key Sources of Industrial VOCs

Liquefied Petroleum Gas (LPG) Emission (13%)Volatilized during LPG storage, transportation, and industrial/domestic use; main components: propane/butane (volatility rate: 90%+ at 25℃).

Motor Vehicles (2%)Includes exhaust (incomplete combustion) and fuel tank volatilization; accounts for a small share of industrial VOCs.

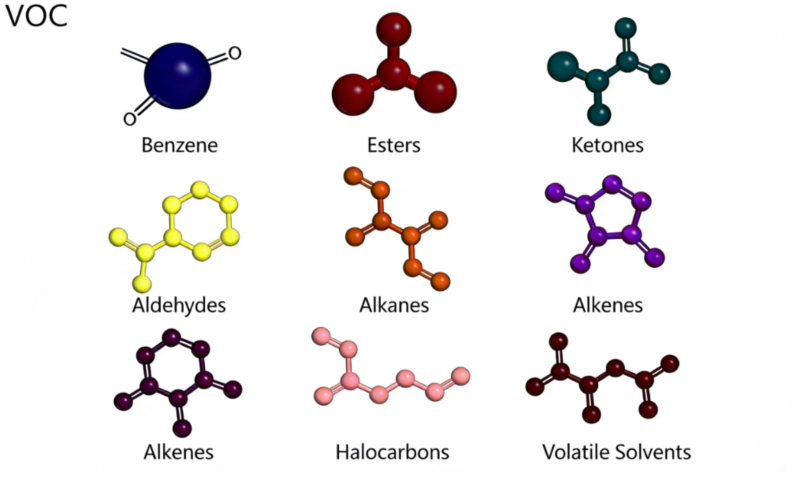

Common industrial VOCs include:

What are VOCs?

- Benzene series

- Esters, ketones, aldehydes

- Alkanes, alkenes, and halogenated hydrocarbons

- Volatile solvents

Key hazards: VOCs not only cause respiratory irritation at concentrations >100 mg/m³ but also contribute to smog formation (accounting for 30-50% of PM2.5 precursors) and ozone layer damage, requiring strict emission control (global standard limit: typically <50 mg/m³ for key pollutants).

How to control VOCs

The core principle of RTO (Regenerative Thermal Oxidation) for VOCs treatment is not simple combustion, but a highly efficient and energy-saving thermal oxidation and energy regeneration process. Its working principle mainly consists of six key steps:

Step 1: Waste gas collection and introduction

VOC-containing waste gas generated during industrial production is first collected centrally through a pipeline system and then transported to the inlet of the RTO equipment by an induced draft fan, in preparation for subsequent treatment.

Step 2: High-efficiency regenerative preheating

Ambient temperature exhaust gas enters the high-temperature ceramic regenerator chamber, which has already been heated in the previous cycle, through a switching valve. As the exhaust gas flows through the honeycomb ceramic body, it is rapidly preheated to near the combustion temperature (typically above 750°C), while the regenerator chamber cools accordingly.

Step 3: High-Temperature Oxidation and Decomposition Core

The preheated exhaust gas enters the combustion chamber, where, with the help of an auxiliary burner or its own calorific value, it rapidly heats up to the design temperature of 760-850℃. At this high temperature, VOCs undergo complete oxidation, their molecular chains break down, and they are converted into harmless carbon dioxide and water.

Step 4: Heat Transfer and Recovery

The high-temperature purified gas (approximately 800℃) after oxidation and decomposition flows into another set of low-temperature heat storage chambers under the guidance of a switching valve. Most of the sensible heat in the purified gas is efficiently absorbed and stored by the honeycomb ceramic body, causing the gas temperature to drop sharply.

Step 5: Cooling and Discharge of Purified Gas

After sufficient heat recovery, the temperature of the purified gas has dropped to only slightly higher than the original intake temperature (typically a temperature rise of <50°C). At this point, the gas fully meets the standards and is safely discharged into the atmosphere through the main fan and chimney.

Step 6: Periodic Switching and Continuous Operation

The control system automatically switches the airflow direction according to a preset cycle (usually 60-120 seconds). The “heat absorption” and “heat release” roles of two or more heat storage chambers alternate, forming a continuous and efficient heat regeneration cycle, thereby achieving stable operation with low energy consumption.

VOCs characteristics

✅ VOCs characteristics suitable for RTO processing:

- Concentration range: Medium to high concentration (>1500 mg/m³ optimal)

- Calorific value requirement: Sufficient calorific value to sustain self-combustion

- Composition requirements: Free from toxic elements such as phosphorus and silicon

- Physical state requirement: Gaseous or volatile liquid

❌ VOCs characteristics unsuitable/requiring pretreatment:

- High concentration of halogens (requires special materials)

- High concentration of particulate matter (requires high-efficiency filtration)

- Extremely high concentration (requires LEL control)

- Contains silicon/phosphorus compounds (will clog ceramics)

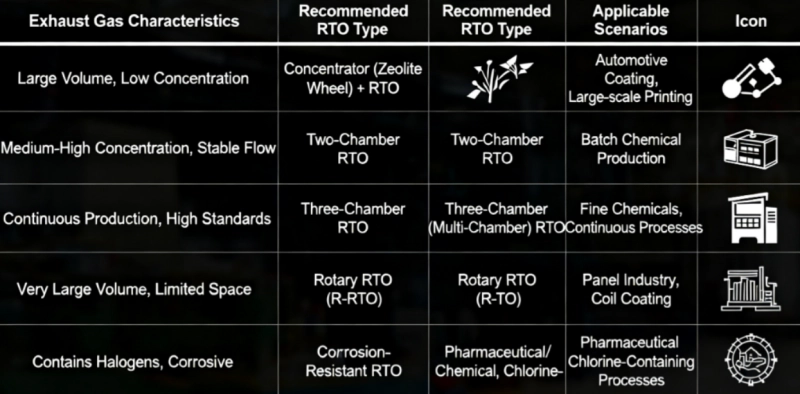

RTO Model Selection Guide

Industry Examples

- Main VOCs: Benzene compounds, esters, ketones

- Concentration characteristics: Low concentration, high air volume

- Recommended solution: Zeolite rotor + three-chamber RTO

- Purification efficiency: 99%

- Energy savings: 40-60%

- Main VOCs: Mixed hydrocarbons, halogenated hydrocarbons

- Concentration characteristics: Medium to high concentration, intermittent emissions

- Recommended solution: Two-chamber RTO + alkaline scrubbing tower

- Key configurations: Explosion-proof design, LEL monitoring

- Main VOCs: Ethyl acetate, ethanol

- Concentration characteristics: Medium concentration, continuous emission

- Recommended solution: Rotary RTO

- Advantages: Low pressure loss, easy maintenance