Coal Mine Gas Treatment Solutions

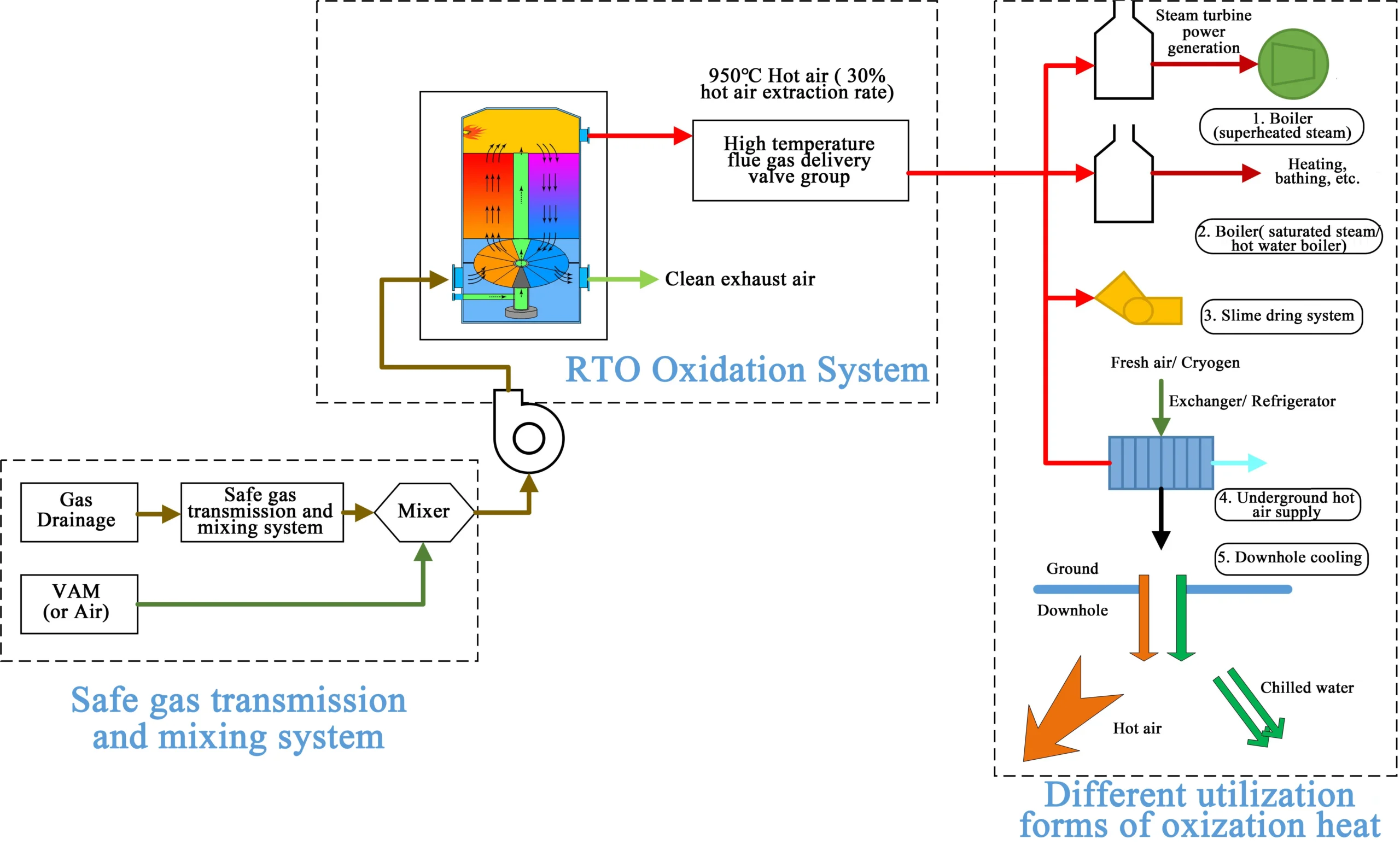

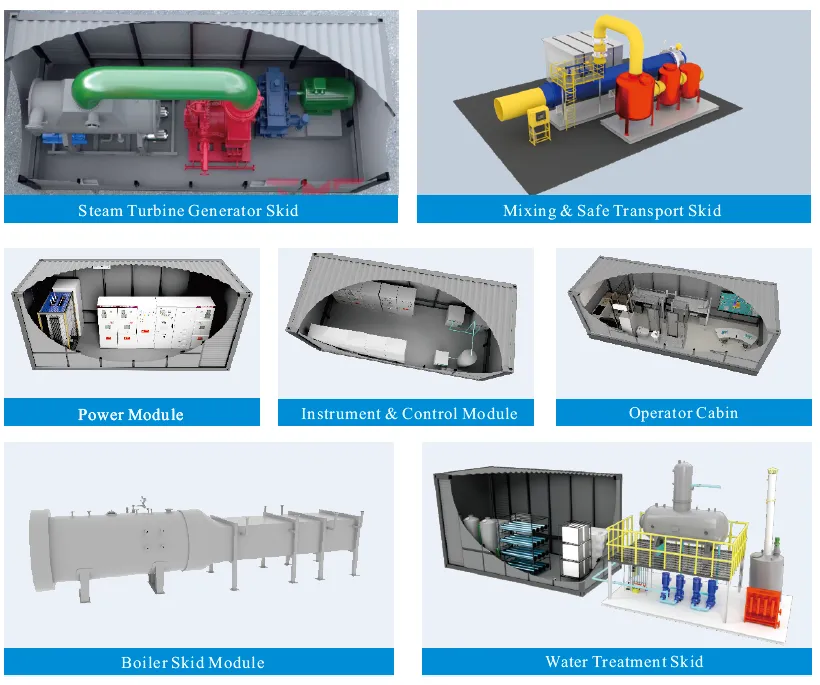

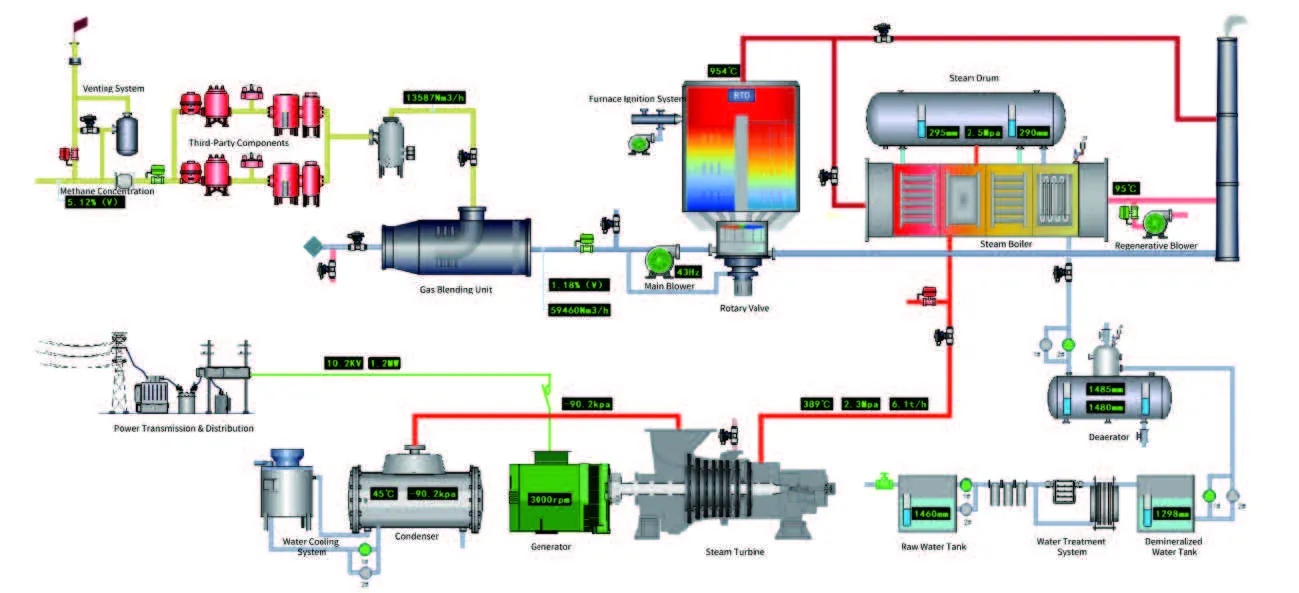

The management plan for coal mine ventilation air methane employs a multi-stage process to ensure safety and environmental sustainability, effectively reducing methane emissions while maximizing energy recovery. RP Techniek BV offers a “Gas-fired Power Generation Island” that utilizes gas with a pure flow rate of 10 m³/min and a concentration below 8% for combined heat and power generation. This system has achieved significant CCER-certified carbon emissions reductions.

- Waste gas composition: Methane (<8%)

- Process solution: Blending system + rotary RTO + waste heat utilization (heating + power generation)

Coal mine gas control process flow chart

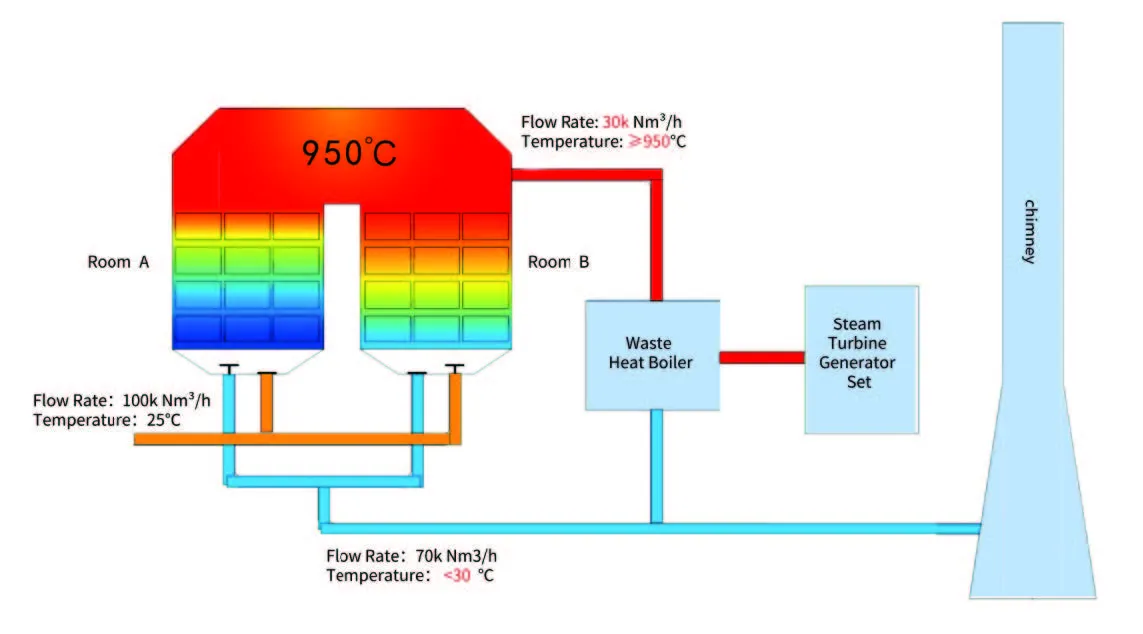

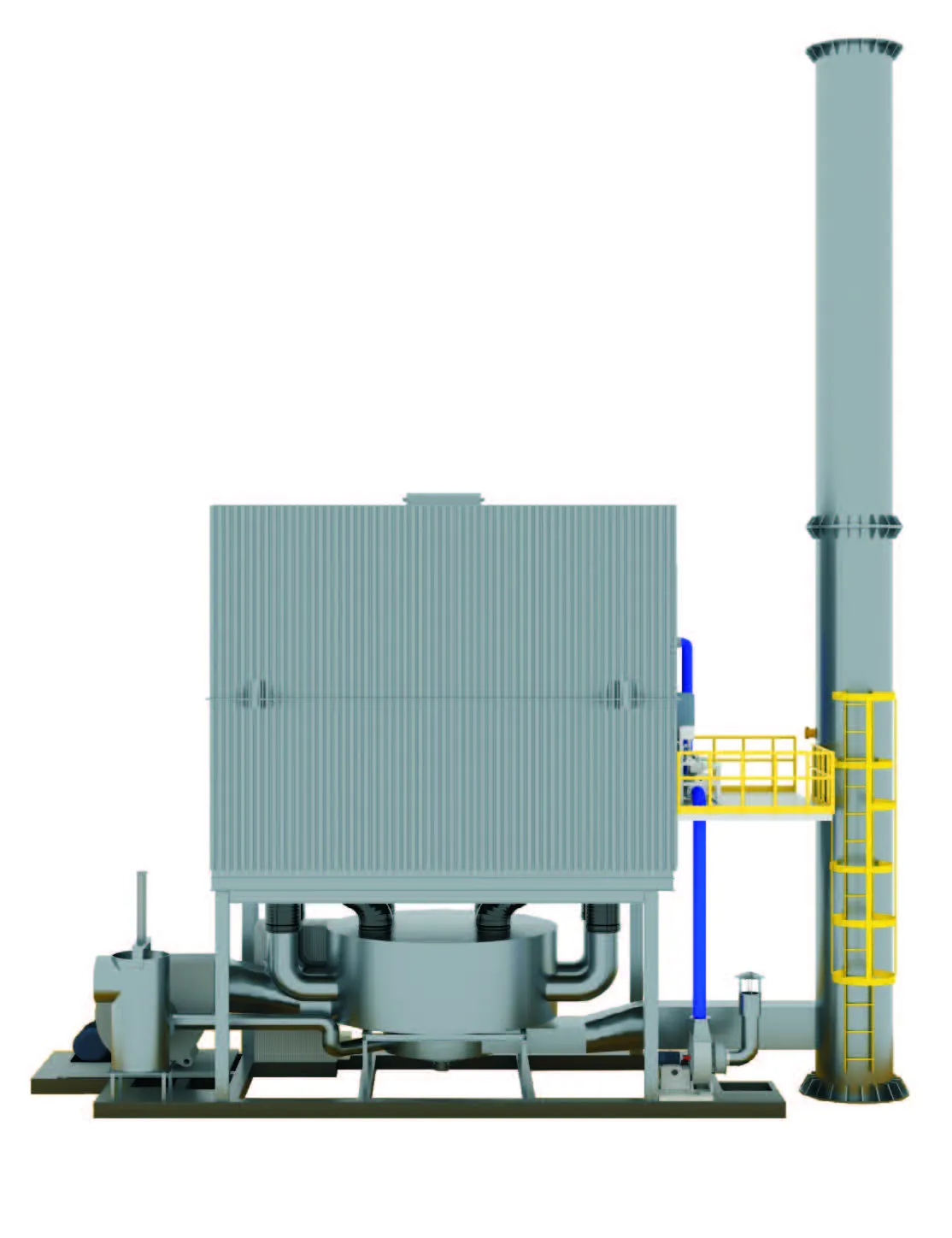

Regenerative Thermal Oxidizer Working Principle

Regenerative Thermal Oxidizers (RTOs) effectively destroy volatile organic compounds (VOCs) through high-temperature oxidation—operating at up to 950°C as illustrated—converting them into carbon dioxide and water vapor. A central feature is the single continuously rotating valve, which replaces multiple conventional poppet valves and partitions the cylindrical heat storage bed into several independent sectors.

During rotation, each sector sequentially performs three functions: preheating incoming polluted gas, storing thermal energy from cleaned gas, and undergoing purging. This continuous rotary motion ensures seamless transitions between operational phases and eliminates pressure fluctuations typical of traditional switching valves.

In the depicted system, polluted gas enters at 25°C with a flow rate of 100k Nm³/h. It passes through hot ceramic sectors for preheating before reaching the combustion chamber, where oxidation occurs at high temperature. After treatment, 30k Nm³/h of the purified gas exits at ≥950°C and can be directed to a waste heat boiler and steam turbine generator set for energy recovery. The remaining 70k Nm³/h transfers heat to cooler ceramic layers before being released below 30°C. A small purified gas stream is used for purging to prevent leakage, while specialized seals ensure gas tightness. This rotary RTO design enhances thermal efficiency, operational reliability, and reduces maintenance needs.

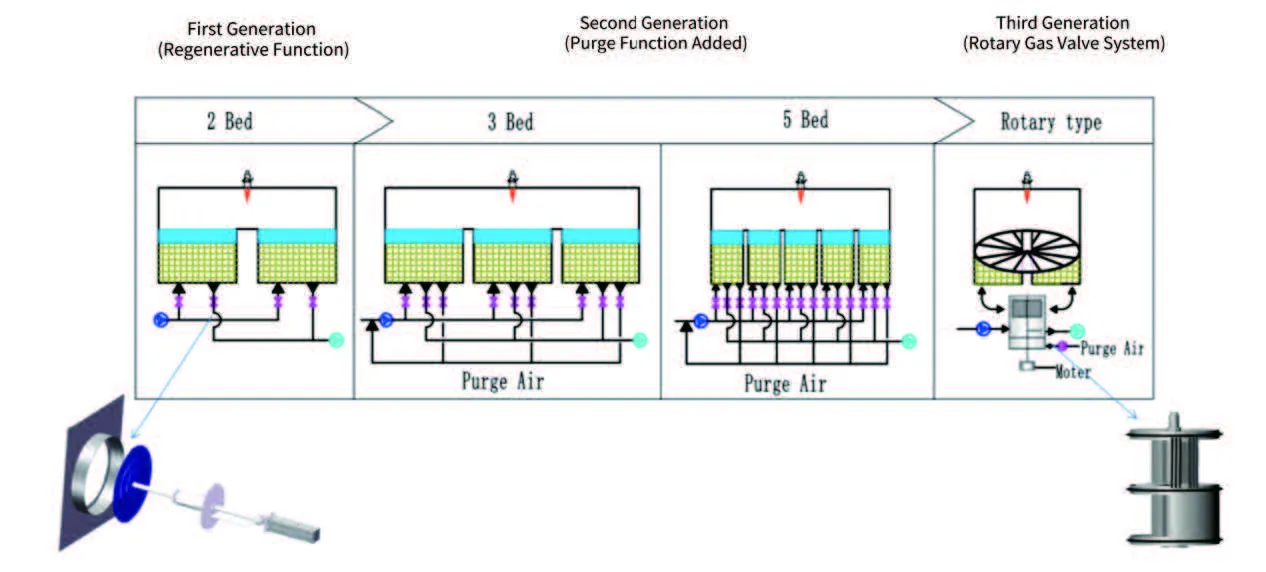

RTO Technology Evolution Roadmap

Key Technologies

- Equipped with a purge function, carbon sequestration benefits increase by 4%.

- Switching valve service life of 30,000 hours.

- High-temperature air intake rate of 30%, heat recovery efficiency of 97%, and 4% higher heat output.

Security Intelligent Control System

- Full-system HAZOP analysis

- High-precision intrinsically safe mixer

- Dustproof/Waterproof/Anti-freezing protection for sensors & instruments

- Fusing-type “concentration limiter”

- “Child Lock” software suite for misuse/prevent wrongful operation

- “Mandatory Maintenance Alert” management software suite

C-box Human-Machine Interface (HMI) Overview Diagram

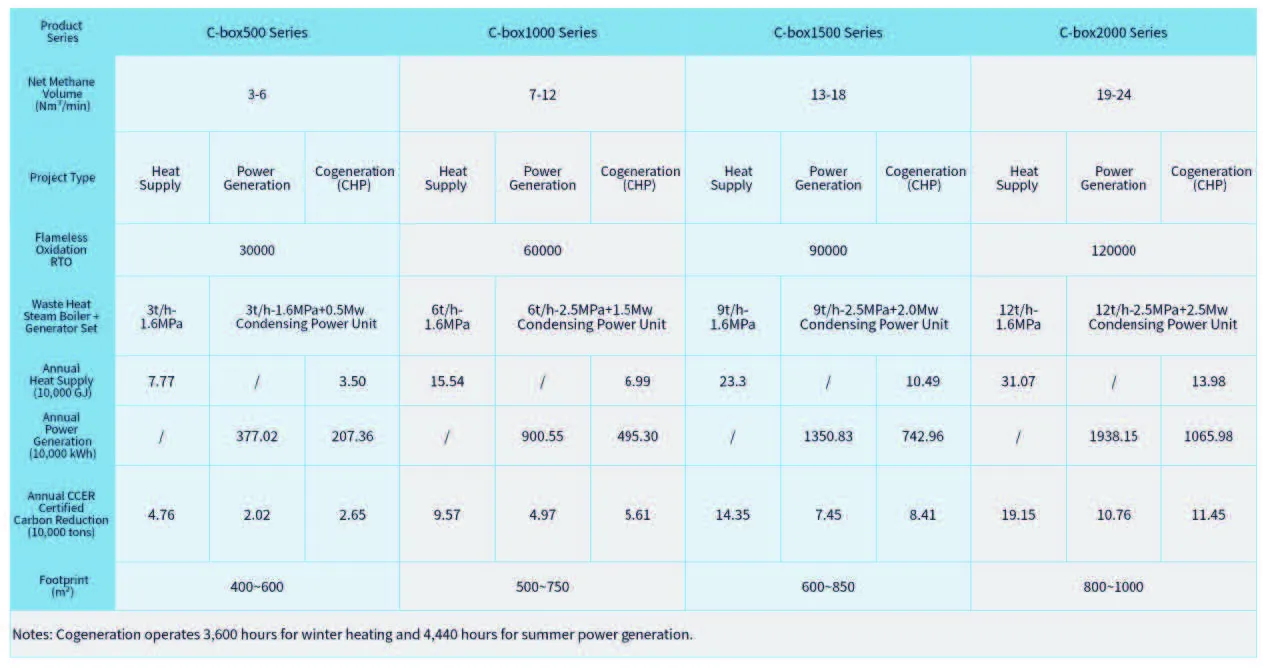

C-box Full Product Series Parameter Table