Executive Summary: The Strategic Significance of RTO Technology for Industrial VOC Control in 2024

In today’s regulatory environment, 蓄热式热氧化器(RTO) systems have evolved from optional pollution control equipment to essential strategic investments for manufacturing sustainability. The evolution of RTO technology represents a fundamental shift in how industrial facilities approach volatile organic compound (VOC) abatement. Modern RTO systems deliver not only compliance with increasingly stringent global emissions standards but also remarkable energy efficiency that transforms operational economics. This comprehensive analysis explores why forward-thinking manufacturers are adopting RTO solutions as core components of their environmental and financial strategies.

Chapter 1: In-depth Technical Analysis of RTO Core Technology Principles

1.1 Thermodynamic Cycle Optimization: Achieving 95%+ Heat Recovery Efficiency

The fundamental engineering breakthrough of RTO technology lies in its revolutionary approach to thermal energy management. Unlike conventional thermal oxidizers that waste heat through exhaust stacks, 蓄热式热氧化器 systems employ a sophisticated multi-chamber design utilizing specialized ceramic heat exchange media. This RTO system configuration operates within the optimal temperature range of 760-850°C, precisely calibrated to ensure complete VOC molecular breakdown while maintaining energy efficiency. The core innovation of the 恢复运营 is not merely in achieving high temperatures but in its ability to capture and reuse up to 97% of the thermal energy that would otherwise be lost in traditional oxidation processes.

The operational sequence of an RTO system follows a precisely controlled cyclic process. Contaminated exhaust enters the first ceramic bed, where it absorbs stored thermal energy, preheating to approximately 90-95% of the target oxidation temperature. This preheated stream then enters the combustion chamber, where supplemental burners or the exothermic heat from VOC oxidation itself elevates it to the precise 760-850°C range required for near-total molecular destruction. The clean, hot exhaust then passes through a second ceramic bed, surrendering its thermal energy before being exhausted. This cyclic process, typically switching every 30-120 seconds depending on RTO system design, creates a continuous loop of energy capture and reuse that distinguishes Regenerative Thermal Oxidation from all other VOC control technologies.

1.2 Ceramic Media Evolution: Advanced Materials Extending RTO Performance Boundaries

The ceramic heat exchange media represents the heart of any RTO system, and material science advancements have dramatically improved RTO technology performance. Traditional cordierite honeycomb ceramics have evolved into sophisticated engineered materials with optimized thermal, mechanical, and chemical properties. Modern RTO ceramic media must balance competing requirements: high surface area for efficient heat transfer, structural integrity to withstand thermal cycling, chemical resistance to acidic combustion byproducts, and minimal pressure drop to reduce fan energy consumption.

| Ceramic Media Type | Surface Area (m²/m³) | Thermal Capacity (kJ/m³·K) | Thermal Conductivity (W/m·K) | Pressure Drop Coefficient | RTO System Impact |

|---|---|---|---|---|---|

| Standard Cordierite Honeycomb | 320-380 | 780-850 | 1.2-1.5 | 1.0 (baseline) | Standard RTO applications |

| High-Density Silicon Carbide | 480-550 | 950-1100 | 3.5-4.5 | 0.85-0.95 | 25% smaller RTO footprint |

| Nanocoated Corrosion-Resistant | 400-450 | 820-900 | 1.8-2.2 | 0.9-1.0 | Extended RTO life in harsh conditions |

| Composite Phase-Change Materials | 600-750 | 1200-1600 | 2.5-3.5 | 0.7-0.8 | 40% higher RTO efficiency |

Latest RTO Material Advancements: Nanocoatings have improved ceramic anti-clogging performance by 40-50%, particularly beneficial for RTO systems processing exhaust streams containing silicones, resins, or other fouling compounds. Phase-change composite materials represent the next frontier in RTO technology, offering significantly higher thermal storage capacity that enables smaller RTO system footprints and improved response to variable VOC loading conditions.

Chapter 2: Comprehensive Industrial Applications of RTO Systems

Chemical Processing: Advanced RTO Solutions for Complex VOC Streams

Problem Statement: A major pesticide intermediates manufacturing facility faced severe operational challenges with its existing VOC control system. The exhaust stream contained a complex mixture of dichloromethane, toluene, xylene, and various halogenated hydrocarbons, with concentrations fluctuating unpredictably between 1-10g/m³ based on batch processing schedules. The previous activated carbon adsorption system required replacement every 3-4 months at a cost exceeding $280,000 annually, while still failing to meet increasingly stringent regulatory limits of 98% VOC destruction efficiency.

Engineered RTO Solution: After comprehensive exhaust characterization and process analysis, engineers specified a custom-designed 3-bed RTO system with several critical enhancements. The 恢复运营 incorporated corrosion-resistant alumina-silicate ceramic media specifically formulated to withstand acidic combustion byproducts from halogenated compounds. A two-stage pretreatment system was integrated upstream, consisting of a high-efficiency cyclone separator for particulate removal followed by a packed-bed scrubber for acid gas neutralization. The RTO system featured advanced online FTIR concentration monitoring with real-time feedback to the combustion control system, allowing automatic adjustment of burner firing rates and bed switching cycles based on actual VOC loading. Additionally, a waste heat boiler was integrated into the 恢复运营 exhaust stream, capturing approximately 2.5 MW of thermal energy for process steam generation.

Quantifiable RTO System Performance Results:

- VOC Destruction Efficiency: Consistently maintained at 99.2-99.5%, exceeding the 98% regulatory requirement

- Operating Cost Reduction: Annual operating expenses decreased from $280,000 to $91,000 (67.5% reduction)

- Energy Recovery: Waste heat boiler generates 4,500 kg/hour of process steam, valued at $185,000 annually

- Payback Period: Total system investment of $1.85M recovered in 2.3 years through combined savings

- Environmental Impact: Annual VOC emissions reduced by approximately 120 metric tons

Automotive Coating: High-Volume RTO Applications with Concentration Enhancement

Operational Scenario: A Tier 1 automotive supplier operating three separate painting lines for vehicle bodies faced escalating compliance challenges. The combined exhaust volume reached 150,000 m³/h with extremely low average VOC concentrations of 200-500 mg/m³ (primarily ethanol, ethyl acetate, and glycol ethers). However, concentration spikes to 2,500 mg/m³ occurred during color change purges and equipment cleaning cycles. The facility needed a solution that could handle this enormous air volume efficiently while maintaining consistent destruction efficiency across widely varying conditions.

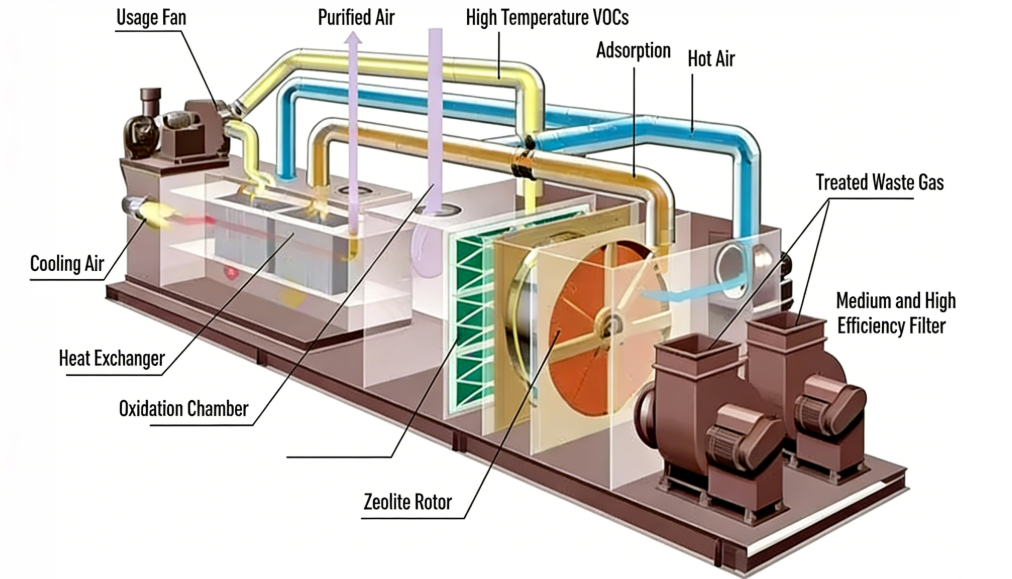

Integrated RTO Technology Approach: Direct application of a conventional RTO system to such a large, dilute stream would have been prohibitively expensive in both capital and operating costs. The engineered solution implemented a hybrid RTO system combining a zeolite rotor concentrator with a compact rotary valve RTO. The concentrator continuously adsorbs VOCs from the main 150,000 m³/h exhaust stream, concentrating them 12-15 times into a smaller 10,000 m³/h desorption air stream. This high-concentration stream (now 2.4-7.5 g/m³) then feeds directly into a specially designed rotary valve RTO. The rotary valve design provides near-continuous flow with minimal pressure fluctuation, critical for maintaining consistent painting booth conditions. The entire RTO system was integrated with the plant’s manufacturing execution system (MES) to anticipate production schedule changes and optimize energy consumption.

Comparative Technology Analysis for This Application:

| Technology Option | Capital Investment | 5-Year Operating Cost | VOC Destruction |

|---|---|---|---|

| Zeolite Rotor + RTO | $3.2M | $1.25M | 99.1% |

| Direct-Fired RTO Only | $5.8M | $3.45M | 98.8% |

| Carbon Adsorption System | $1.9M | $4.75M | 94.5% |

| Selected RTO Solution Advantage | 45% lower than direct RTO | 64% lower than carbon system | Compliance margin +1.1% |

Chapter 3: Detailed Economic Analysis of RTO System Investments

3.1 Life Cycle Cost Modeling for RTO System Evaluation

Evaluating the true economic value of an RTO system requires comprehensive life cycle cost analysis (LCCA) that extends beyond simple capital equipment comparison. A properly executed LCCA for an RTO investment examines all cost components over a 15-20 year operational horizon, accounting for inflation, energy price escalation, maintenance requirements, and potential regulatory changes. The economic superiority of modern RTO technology becomes apparent when comparing total cost of ownership rather than just initial purchase price.

| Cost Component Category | High-Efficiency RTO System | Conventional RTO System | Catalytic Oxidizer (RCO) | 15-Year Comparative Advantage |

|---|---|---|---|---|

| Initial Capital Investment Equipment, installation, commissioning |

$1,150,000 | $950,000 | $1,050,000 | -$200,000 vs. conventional |

| Annual Natural Gas Consumption Based on 50,000 Nm³/h, 2.5 g/Nm³ VOC |

$18,500 | $132,000 | $85,000 | $1.7M savings vs. conventional |

| Annual Electrical Power Fans, valves, controls, instrumentation |

$52,000 | $61,000 | $48,000 | $135,000 savings |

| Annual Maintenance Expenses Preventive, corrective, parts replacement |

$24,000 | $31,000 | $38,000 | $105,000 savings vs. RCO |

| Consumables & Catalyst Ceramic media, catalyst, other consumables |

$3,500 | $4,200 | $28,000 | $367,500 savings vs. RCO |

| 15-Year Total Cost of Ownership Net Present Value @ 6% discount rate |

$2,815,000 | $3,950,000 | $3,420,000 | $1,135,000 advantage |

Key Economic Finding: RTO System Payback Analysis

The additional $200,000 investment in a high-efficiency RTO system versus a conventional design is recovered in approximately 3.2 years through operational savings alone. Over a 15-year operational life, the high-efficiency 恢复运营 delivers a net present value advantage exceeding $1.1 million compared to conventional thermal oxidation technologies. When potential revenue from waste heat recovery is included (typically $50,000-$150,000 annually depending on local energy costs), the economic argument for advanced RTO technology becomes overwhelmingly compelling for most industrial applications.

3.2 RTO System Financial Justification Methodology

Developing a robust financial justification for RTO system implementation requires a structured approach that captures both quantitative and qualitative benefits. The methodology should begin with comprehensive baseline establishment, documenting current VOC control costs, energy consumption patterns, maintenance expenses, and compliance status. Next, a detailed technical specification for the proposed RTO system must be developed, including all associated costs and performance guarantees. The financial analysis should then model multiple scenarios incorporating varying energy price escalation rates (typically 3-5% annually), potential regulatory changes, and different operational assumptions.

Critical financial metrics for RTO system evaluation include Net Present Value (NPV), which should be positive for viable projects; Internal Rate of Return (IRR), which typically exceeds 20-35% for well-designed RTO investments; and Discounted Payback Period, which generally ranges from 2.5 to 4.5 years for properly specified systems. Additionally, the analysis should account for potential RTO system revenue streams, including waste heat monetization, carbon credit generation in regulated markets, and avoided compliance costs from increasingly stringent emissions regulations. Qualitative factors such as improved corporate sustainability ratings, enhanced community relations, and reduced regulatory risk exposure should also be documented, as these increasingly influence investment decisions in modern manufacturing organizations.

Chapter 4: RTO System Design Optimization and Technical Considerations

Q1: How to Design RTO Systems for Halogenated VOC Streams?

Technical Challenge: Halogenated compounds (chlorinated, fluorinated, brominated VOCs) present unique challenges for RTO systems due to acidic combustion byproduct formation (HCl, HF, HBr) and potential dioxin/furan generation under certain conditions.

Comprehensive RTO Design Solution:

- Material Selection: Specify 310S stainless steel or Inconel 625 for all hot section components exposed to temperatures above 300°C. Ceramic media should be acid-resistant formulation with minimal iron content to reduce catalytic dioxin formation.

- Temperature Management: Maintain combustion chamber temperature between 850-950°C with minimum 2.0 seconds residence time to ensure complete destruction while minimizing dioxin formation in the “de novo synthesis” window (250-450°C).

- Quench System Integration: Install immediate quench system after the 恢复运营 to rapidly cool exhaust from 850°C to below 200°C within 0.5 seconds, effectively “freezing” the gas composition before dioxins can form.

- Secondary Treatment: Follow the RTO system with packed-bed scrubber using 15-20% caustic solution for acid gas removal, achieving >99.5% HCl/HF removal efficiency.

- Continuous Monitoring: Implement continuous emissions monitoring for both VOCs and acid gases, with automatic system adjustment based on real-time measurements.

Q2: Optimal RTO System Configuration for Variable Process Conditions?

Operational Reality: Most industrial processes experience significant variability in exhaust volume, VOC concentration, and composition due to production scheduling, batch operations, or equipment cycling.

Advanced RTO System Configuration Strategies:

- Multi-Bed RTO Designs: Implement 3-bed, 5-bed, or even 7-bed RTO configurations to provide operational flexibility. Additional beds allow for more frequent valve switching during high-concentration periods (reducing VOC slip) and bed isolation during low-flow conditions.

- Variable Frequency Drive (VFD) Integration: All major fans in the RTO system should be equipped with VFDs controlled by differential pressure sensors, allowing automatic airflow adjustment while maintaining optimal pressure profiles.

- Predictive Control Algorithms: Implement model predictive control (MPC) that uses historical data and real-time process inputs to anticipate changes and pre-adjust RTO system parameters.

- Hybrid System Approaches: For processes with extreme variability (e.g., 10:1 turndown ratios), consider hybrid systems combining RTO technology with concentration technologies for optimal economic performance.

Customizing Exceptional RTO Solutions for Your Business

Through this guide, you’ve learned how modern Regenerative Thermal Oxidation technology transforms environmental compliance requirements into substantial economic benefits. From over 95% heat recovery efficiency to over 99% VOC destruction rates, from engineering designs for complex operating conditions to 3-4 year return on investment periods—RTO has