In the Netherlands, from the Leiden Bio Science Park to the pharmaceutical clusters in Oss, the management of Volatile Organic Compounds (VOCs) has become a cornerstone of business continuity. As the Dutch government tightens enforcement of the Activiteitenbesluit milieubeheer (Activities Decree), the 蓄热式热氧化器(RTO) has emerged as the premier technology for softgel and injectable manufacturers due to its unparalleled energy recovery and destruction efficiency.

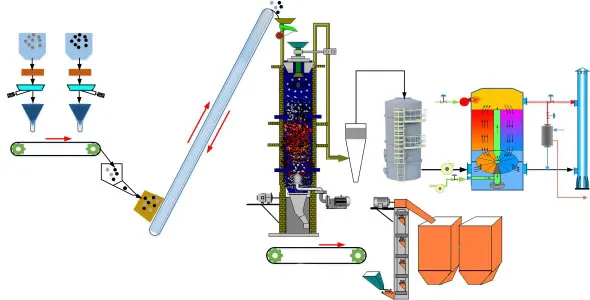

What is an RTO? (Regenerative Thermal Oxidizer)

An RTO is an advanced industrial environmental system designed to oxidatively decompose organic pollutants (VOCs) at high temperatures, typically between 815°C and 980°C.

Core Working Principle

The operational logic of an RTO centers on “High-Temperature Oxidation + High-Efficiency Thermal Regeneration“:

- Oxidation Phase: VOCs enter the combustion chamber where thermal energy breaks down organic molecules into harmless Carbon Dioxide ($CO_2$) and Water Vapor ($H_2O$).

- Regeneration Phase: The system utilizes specialized ceramic heat exchange media. As purified hot gas exits, the heat is absorbed by the ceramics; when cold raw gas enters the next cycle, the stored heat preheats the incoming stream.

- Cyclic Operation: Precise valve switching maintains thermal efficiency, often allowing the system to achieve “auto-thermal operation” (sustaining oxidation without auxiliary fuel) at specific VOC concentrations.

RTO Core Technical Parameters

The performance of an RTO is defined by several critical engineering metrics. These parameters determine compliance with Dutch NeR (Netherlands Emission Guidelines) or US EPA standards.

Key Parameter Benchmark Table

| Technical Metric | Parameter Range | Impact on Performance | Reference Standard |

|---|---|---|---|

| Operating Temperature | 815 – 980°C (1500 – 1800°F) | Dictates the thermodynamic integrity of VOC destruction. | EPA 452/B-02-001 |

| VOC Destruction (DRE) | ≥ 99% (up to 99.9%) | Ensures emissions stay below the strict 20mg/m³ limit. | EU IED 2010/75/EU |

| Thermal Recovery (TER) | 95% – 97% | Directly reduces natural gas/auxiliary fuel consumption. | Industry Energy Whitepapers |

| Gas Residence Time | 0.5 – 1.0 Seconds | Ensures complete molecular breakdown in the hot zone. | Chemical Kinetic Modeling |

| Flow Capacity | 2,000 – 80,000+ scfm | Defines the physical processing throughput of the unit. | Engineering Design Codes |

| System Resistance (ΔP) | 2500 – 4500 Pa | Affects the power consumption of the main fan. | Fluid Dynamics Calc |

| Valve Leakage Rate | < 0.1% | Prevents untreated bypass gas from entering the stack. | Zero-leak Poppet Design |

Technical Deep Dive

- Destruction Efficiency: For pharmaceutical solvents like Isopropanol or Ethanol, 99%+ DRE is mandatory. Dropping below 760°C significantly reduces efficiency and can lead to incomplete combustion byproducts like Carbon Monoxide.

- 能量回收: A TER of 95%+ means the temperature delta between inlet and outlet gas is minimal (typically 30-50°C), which is crucial in high-energy-cost markets like the EU.

Application Characteristics, Advantages, and Limitations

1. The Ideal Use Case: High Volume, Low-to-Mid Concentration

RTOs excel in pharmaceutical environments with airflows above 5,000 $m^3/h$. Because GMP requirements mandate high ventilation rates, the resulting exhaust is often “large volume but dilute,” which perfectly suits the RTO’s regenerative logic.

2. Core Strategic Advantages

- Exceptional Energy ROI: At the “auto-thermal point,” the VOCs act as the primary fuel, making the process nearly self-sustaining.

- Lower OPEX: Long-term operating costs are 60-80% lower than traditional Thermal Oxidizers (TO).

- Decarbonization: By minimizing fossil fuel use, RTOs align with the Dutch Klimaatakkoord (Climate Agreement) goals.

3. Limitations & Mitigation

- High Concentration Risks: If concentrations exceed 25% LEL, the system risks overheating. Solution: Use Hot Gas Bypass or fresh air dilution.

- Particulate Fouling: Pharmaceutical dust or oil mists can clog ceramics. Solution: Install high-efficiency pre-filtration (e.g., G4+F7+H13).

Critical Components & Ecosystem Support

- Ceramic Media: High-density honeycomb ceramics or Mullite. High surface area is key for heat transfer.

- Switching Valves (Poppet Valves): Must be pneumatic zero-leakage valves to prevent untreated gas “slips.”

- Burners: Modulating burners (e.g., Maxon or Eclipse) provide precise control during start-up.

- Secondary Heat Recovery: Redirecting residual heat to factory HVAC or water pre-heating systems for maximum efficiency.

Mainstream RTO Brand Comparison

| Brand | Core Strength | TER / DRE | Decision Logic |

|---|---|---|---|

| Dürr (Ecopure) | German engineering; ultra-stable. | 97% / 99.9% | Best for high-budget, high-risk pharma clusters. |

| Ever-Power | Strong Integration; niche expert in Softgel/Injectables. | 96% / 99.5% | Best for Cost-Performance & specialized industrial skids. |

| Anguil | Expertise in corrosive/halogenated exhaust. | 95% / 99% | Ideal for complex chemical synthesis/purification. |

Global Regulatory Context & Local SEO (Netherlands)

1. Netherlands & EU Market

In the Netherlands, the ILT (Human Environment and Transport Inspectorate) enforces strict VOC management plans.

- 遵守: EU IED (Industrial Emissions Directive).

- Subsidies: Dutch companies can leverage EIA (Energie-investeringsaftrek) for significant tax deductions on RTO investments.

2. Global Benchmarks

- USA: Governed by EPA Method 25A.

- China: GB 37822-2019 standards make RTOs a prerequisite for chemical park entry.

Field Experience & Case Studies

Field Insight: The “Clogging” Lesson

In a project in Noord-Brabant, we observed a pressure drop spike within three months.

- The Issue: Trace oil mists from softgel production were carbonizing on the ceramic surface.

- The Fix: Retrofitting a three-stage filtration system and an automatic “bake-out” cycle.

- Lesson: Pre-treatment is the “heart” that determines the life of your RTO.

Case Study: Dutch Pharma Major (50,000 $m^3/h$)

- 背景: High OPEX from carbon beds and unstable ethanol emissions.

- Solution: 3-Tower RTO + Secondary Energy Recovery.

- Results: DRE stabilized at 99.5%; annual natural gas savings exceeded €120,000.

Future Trends: The Next Generation of RTOs

- RTO + Carbon Capture (CCUS): Capturing clean $CO_2$ for use in Dutch greenhouses.

- Hydrogen-Ready Burners: Transitioning to zero-carbon auxiliary fuels.

- AI Maintenance: Using machine learning to predict load fluctuations and optimize valve cycles.

Conclusion: For Dutch and global pharma enterprises, a high-spec 恢复运营 is not just an environmental cost—it is a strategic asset for achieving a “Green Factory” vision.