In the furniture manufacturing industry, the coating process is essential for product quality but remains a “high-risk” area for environmental compliance. From rosewood furniture hubs in Vietnam to panel furniture clusters across Asia and Europe, producers face unprecedented pressure to reduce emissions.

Wood furniture exhaust typically features high airflow volumes, low VOC concentrations, and sticky paint mist. Traditional carbon adsorption is not only expensive to maintain but also poses safety risks. How can you achieve compliant emissions with low energy consumption? The combination of “Zeolite Rotor Concentration + Rotary RTO” has become the industry-recognized ultimate solution.

Core Challenges: Why Do Furniture Waste Gas Systems Often Fail?

1. Why is paint mist pre-treatment the key to success?

Exhaust from furniture spraying contains significant amounts of viscous paint mist. If pre-treatment is inadequate, this mist will rapidly clog the Zeolite Rotor or the RTO ceramic media, leading to system failure. Therefore, high-efficiency “Wet Scrubbing + Multi-stage Dry Filtration” is the “life support system” of the entire unit.

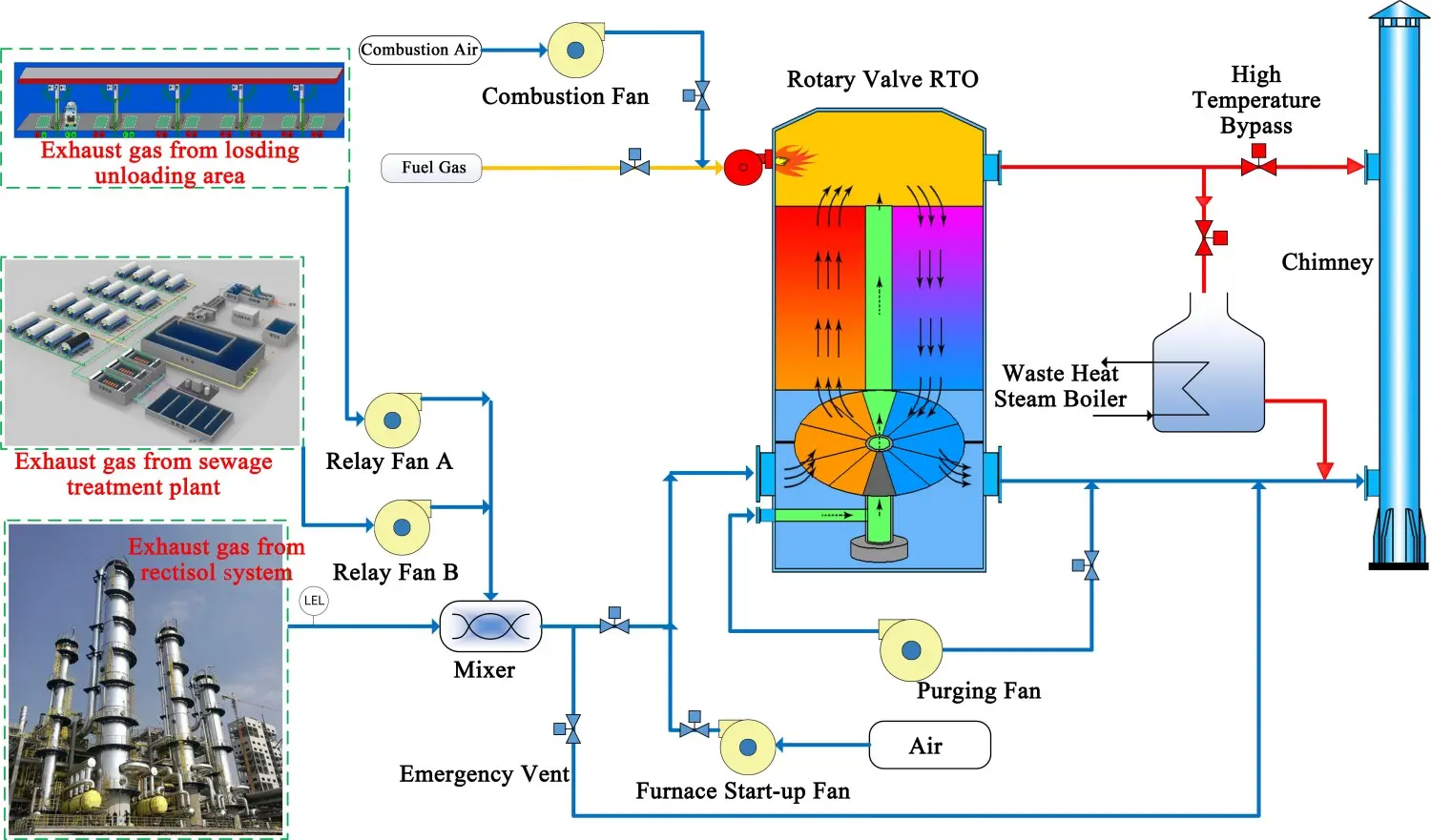

2. What is the “Rotor Concentrator + RTO” combination?

Because spray booth airflows are massive but VOC concentrations are low, direct incineration is extremely energy-intensive. The system first uses a 沸石转子 to concentrate the large-volume exhaust into a small-volume, high-concentration stream (typically by a factor of 10-20x). This stream is then sent to the 恢复运营 for high-temperature oxidation, achieving “waste-to-energy” and drastically cutting operating costs.

3. How do you handle reactive components like Styrene?

Styrene, common in wood coatings, can easily polymerize inside the rotor, leading to “poisoning” of the zeolite. This requires the system to have precise temperature control and a regular high-temperature thermal desorption/regeneration function.

Technical Parameters: The Professional Selection Benchmark

A high-performance furniture exhaust system’s value is hidden in these core engineering metrics:

Key Technical Parameters Table

| Technical Metric | Parameter Range | Impact on Furniture Production | Reference Standard |

|---|---|---|---|

| Mist Capture Efficiency | ≥ 99.5% | Prevents clogging of the rotor; extends equipment life. | Clean Coating Standards |

| Concentration Ratio | 10:1 – 25:1 | Determines the VOC density for RTO and energy savings. | Zeolite Design Codes |

| RTO Oxidation Temp | 815 – 900°C | Ensures full oxidation of Butyl Acetate and BTEX. | EPA 452/B-02-001 |

| Total VOC Removal (DRE) | ≥ 98% | Ensures compliance with strict environmental audits. | EU IED Directive |

| Thermal Recovery (TER) | 95% – 97% | Determines if the system can run without auxiliary fuel. | Industrial Energy Codes |

| System Energy Usage | 60-80% lower than TO | Directly impacts the monthly factory utility budget. | Field Test Data |

Operational Impact of Parameters:

- Thermal Energy Recovery (TER): For coating lines, a TER above 95% means that with a proper concentration ratio, the RTO can run nearly self-sufficiently without consuming extra natural gas during steady operation.

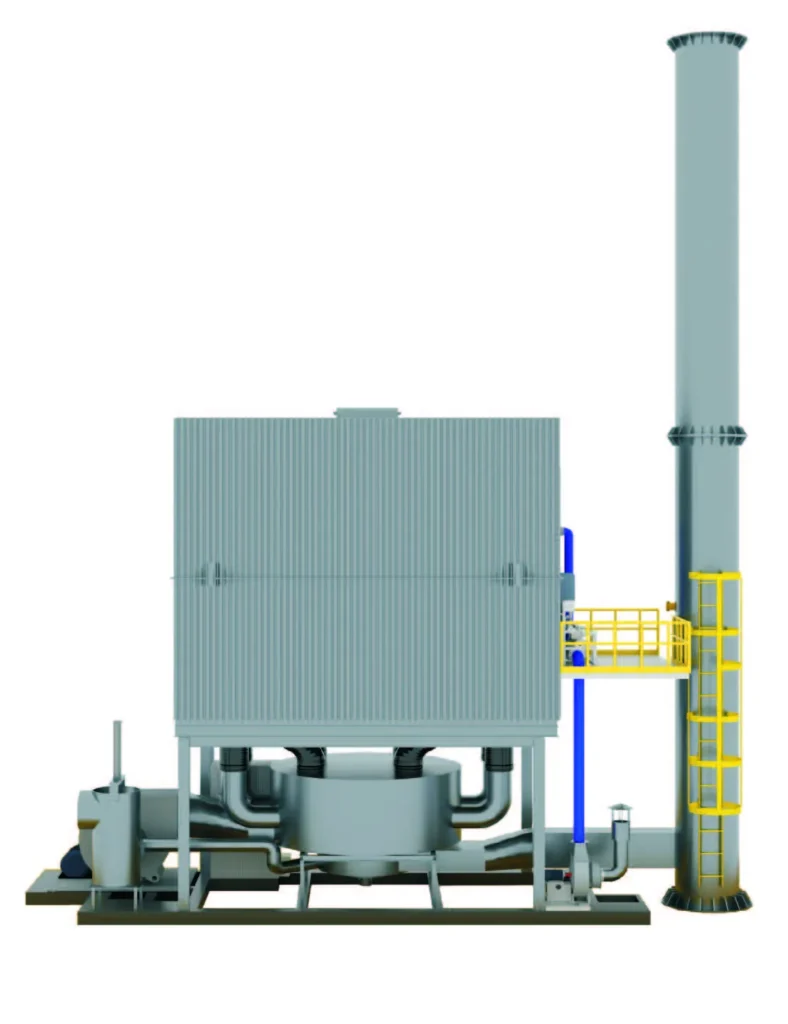

- Advantages of Rotary RTO: Compared to traditional bed-type RTOs, the rotary design eliminates pressure fluctuations (water hammer effect), causing minimal interference with the spray booth’s micro-positive pressure environment and ensuring superior coating finishes.

Abatement Scenario: Characteristics and Limitations

Scenario Analysis: Spray Booth Exhaust (High Volume, Multi-component)

- Characteristics: Contains solvents (Toluene, Xylene, Ethyl Acetate) and paint mist particles.

- Advantages:

- Maximum Energy Saving: Minimizes treatment costs through rotor concentration.

- High Space Efficiency: The Rotary RTO is compact, making it ideal for retrofitting older plants with limited space.

- Limitations:

- Humidity Sensitivity: If humidity exceeds 80% RH, dehumidification is required to maintain zeolite adsorption efficiency.

- Mist Dependency: 70% of system success depends on the diligent maintenance and replacement of the pre-filters.

Critical RTO Components & Ecosystem Recommendations

- High-Hydrophobicity Zeolite Rotor: Specifically selected molecular sieves for polar solvents found in furniture coatings.

- Multi-stage Pleated Dry Filters: G4, F7, and F9 staged interception to ensure dust levels entering the rotor are < 1mg/m³.

- Variable Frequency Drive (VFD) Fans: Automatically adjusts airflow based on the number of active spray booths, saving significant electricity.

- Safety Instrumented System (SIS): Equipped with online LEL (Lower Explosive Limit) detection to prevent flash explosions from high-concentration surges.

Mainstream RTO Brand Comparison (Furniture Industry Focus)

| Brand | Core Strength | Application Scenario | Decision Logic |

|---|---|---|---|

| Dürr (Ecopure) | Top-tier integration; extremely stable performance. | Large-scale automotive or global furniture plants. | The premium choice for high-budget projects. |

| Ever-Power | Targeted Pre-treatment; excels at solving “sticky mist” issues. | Export-oriented furniture hubs in SE Asia and Europe. | Best for Cost-Performance and agile maintenance services. |

| Tecam | Expertise in complex chemical solvents and corrosion resistance. | High-end custom furniture and artistic coating. | Ideal for niche markets with unique solvent profiles. |

Global Compliance & Local Opportunities (SEO Strategy)

For furniture exporters, environmental compliance is not just a legal requirement—it is a “Green Passport” for international orders.

- Regulatory Compliance:

- USA: Regulated under 40 CFR Part 63 Subpart JJ.

- EU: Strict adherence to the Solvent Emissions Directive.

- Subsidies & Support: In regions like the Netherlands, investing in such high-efficiency systems often qualifies for the EIA (Energie-investeringsaftrek) energy investment tax deduction.

Field Experience & Case Studies

Expert Insight: Rescuing a “Clogged” Rotor

In a large-scale wooden door production project, the client’s original system failed within six months because the paint mist had bypassed the filters and ruined a million-dollar zeolite rotor.

- Solution: We redesigned a five-stage filtration system and replaced the unit with an Ever-Power Rotary RTO combination.

- Outcome: VOC removal stabilized at 99%+. While annual filter replacement costs rose by 5%, it was negligible compared to the losses from production downtime and rotor replacement.

Future Trends: The Green Furniture Supply Chain

- UV Coatings + RTO Synergy: Since UV-cured exhaust is low-volume but high-concentration, it can be fed directly into an RTO for full thermal self-sufficiency.

- Digital Environmental Dashboards: Cloud-based monitoring allows manufacturers to show the “Carbon Footprint” of their products to end consumers, adding significant brand value.

Conclusion: There are no shortcuts in furniture exhaust treatment. Only through “Precision Pre-treatment + Efficient Concentration + Complete Incineration” can furniture makers maintain their footing in the era of strict environmental regulation.