В Нидерландах, из Лейденский бионаучный парк к фармацевтическим кластерам в ОссУправление летучими органическими соединениями (ЛОС) стало краеугольным камнем обеспечения непрерывности бизнеса. Поскольку правительство Нидерландов ужесточает контроль за соблюдением этих норм, Activiteitenbesluit milieubeheer (Указ о деятельности), Регенеративный термоокислитель (РТО) Благодаря беспрецедентной эффективности извлечения энергии и разрушения, эта технология стала ведущей для производителей мягких желатиновых капсул и инъекционных препаратов.

Что такое РТО? (Регенеративный термический окислитель)

Реактор с окислительной термизацией (RTO) — это передовая промышленная система защиты окружающей среды, предназначенная для окислительного разложения органических загрязнителей (ЛОС) при высоких температурах, обычно в диапазоне от до . 815°C и 980°C.

Основной принцип работы

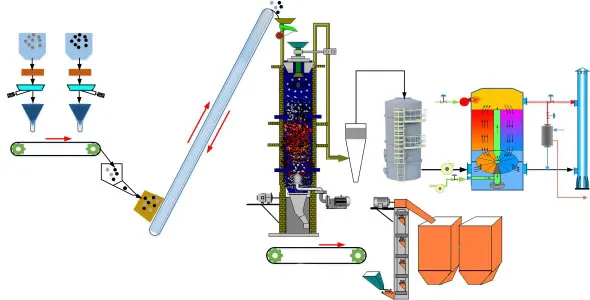

Логика работы RTO (Registered Transport Objective) основана на следующем:Высокотемпературное окисление + высокоэффективная термическая регенерация“:

- Фаза окисленияЛетучие органические соединения попадают в камеру сгорания, где тепловая энергия расщепляет органические молекулы на безвредные вещества. Углекислый газ ($CO_2$) и Водяной пар ($H_2O$).

- Фаза регенерацииСистема использует специализированные керамический теплообменный материалПо мере выхода очищенного горячего газа тепло поглощается керамикой; когда холодный неочищенный газ поступает в следующий цикл, накопленное тепло предварительно нагревает входящий поток.

- Циклическая работаТочное переключение клапанов поддерживает тепловую эффективность, часто позволяя системе достичь «автотермический режим«(поддержание окисления без дополнительного топлива) при определенных концентрациях ЛОС.»

Основные технические параметры RTO

Эффективность работы RTO определяется несколькими критически важными инженерными показателями. Эти параметры определяют соответствие голландским стандартам. НеР (Руководящие принципы выбросов Нидерландов) или США Агентство по охране окружающей среды стандарты.

Таблица сравнения ключевых параметров

| Технический показатель | Диапазон параметров | Влияние на производительность | Эталонный стандарт |

|---|---|---|---|

| Рабочая температура | 815 – 980°C (1500 – 1800°F) | Определяет термодинамическую целостность процесса разрушения летучих органических соединений. | EPA 452/B-02-001 |

| Уничтожение летучих органических соединений (ЛОС) | ≥ 99% (до 99,9%) | Обеспечивает поддержание уровня выбросов ниже строгого предела в 20 мг/м³. | Директива ЕС 2010/75/ЕС |

| Тепловая рекуперация (TER) | 95% – 97% | Непосредственно снижает потребление природного газа/вспомогательного топлива. | Аналитические документы по энергетике в промышленности |

| Время пребывания газа | 0,5 – 1,0 секунды | Обеспечивает полное молекулярное расщепление в горячей зоне. | Моделирование химической кинетики |

| Пропускная способность | 2000–80000+ стандартных кубических футов в минуту | Определяет физическую пропускную способность обработки данных устройством. | Нормативы проектирования в машиностроении |

| Сопротивление системы (ΔP) | 2500 – 4500 Па | Влияет на энергопотребление основного вентилятора. | Расчет гидродинамики |

| Скорость утечки клапана | < 0.1% | Предотвращает попадание неочищенного отработанного газа в дымовую трубу. | Конструкция клапана с нулевой утечкой |

Технический подробный анализ

- Эффективность разрушения: Для фармацевтических растворителей, таких как Изопропанол или Этанол99%+ DRE является обязательным. Падение температуры ниже 760°C значительно снижает эффективность и может привести к неполному сгоранию побочных продуктов, таких как окись углерода.

- рекуперация энергииЗначение TER 95%+ означает, что разница температур между входящим и выходящим газом минимальна (обычно 30-50°C), что имеет решающее значение на рынках с высокими ценами на энергию, таких как ЕС.

Характеристики, преимущества и ограничения применения.

1. Идеальный сценарий использования: большой объем, низкая или средняя концентрация.

Регенеративные термические окислители (РТО) превосходно зарекомендовали себя в фармацевтической промышленности при расходе воздуха выше 5000 1Т4Тм³/ч1Т4Т. Поскольку требования GMP предусматривают высокие скорости вентиляции, образующийся отвод воздуха часто имеет «большой объем, но разбавлен», что идеально соответствует регенеративной логике РТО.

2. Ключевые стратегические преимущества

- Исключительная окупаемость инвестиций в энергетику.В «автотермической точке» летучие органические соединения выступают в качестве основного топлива, что делает процесс практически самоподдерживающимся.

- Снижение операционных расходовДолгосрочные эксплуатационные расходы на 60-80% ниже, чем у традиционных термических окислителей (ТО).

- ДекарбонизацияМинимизируя использование ископаемого топлива, региональные транспортные организации соответствуют голландской модели. Климататаккоорд Цели (Климатического соглашения).

3. Ограничения и меры по их смягчению

- Риски, связанные с высокой концентрациейЕсли концентрация превысит 25% LEL, система рискует перегреться. РешениеИспользуйте обходной путь для горячего газа или разбавление свежим воздухом.

- Загрязнение частицамиФармацевтическая пыль или масляные туманы могут забивать керамические конструкции. РешениеУстановите высокоэффективную предварительную фильтрацию (например, G4+F7+H13).

Критические компоненты и поддержка экосистемы

- Керамические материалыВысокоплотная сотовая керамика или муллит. Большая площадь поверхности является ключевым фактором для теплопередачи.

- Переключающие клапаны (золотниковые клапаны)Для предотвращения утечки необработанного газа необходимо использовать пневматические клапаны с нулевой утечкой.

- ГорящиеМодулирующие горелки (например, Maxon или Eclipse) обеспечивают точное управление во время запуска.

- Вторичная рекуперация тепла: Перенаправление остаточного тепла в заводские системы отопления, вентиляции и кондиционирования воздуха или системы предварительного подогрева воды для достижения максимальной эффективности.

Сравнение основных брендов RTO

| Бренд | Сила мышц корпуса | ТЕР / ДРЕ | Логика принятия решений |

|---|---|---|---|

| Дюрр (Экопуре) | Немецкое машиностроение; сверхстабильность. | 97% / 99.9% | Идеально подходит для фармацевтических кластеров с большим бюджетом и высоким уровнем риска. |

| Вечная Сила | Сильная интеграция; узкоспециализированный эксперт в области мягких желатиновых капсул/инъекционных препаратов. | 96% / 99.5% | Лучше всего подходит для Соотношение цены и качества и специализированные промышленные платформы. |

| Ангиль | Экспертиза в области коррозионно-активных/галогенных выхлопных газов. | 95% / 99% | Идеально подходит для сложных химических синтезов/очистки. |

Глобальный нормативно-правовой контекст и локальная SEO-оптимизация (Нидерланды)

1. Рынок Нидерландов и ЕС

В Нидерландах ИЛТ Инспекция по охране окружающей среды и транспорту (Human Environment and Transport Inspectorate) обеспечивает строгое соблюдение планов управления летучими органическими соединениями.

- Согласие: Директива ЕС о промышленных выбросах (EU IED).

- СубсидииГолландские компании могут использовать это преимущество. EIA (Энерго-инвесторсафтрек) для получения значительных налоговых вычетов по инвестициям в RTO.

2. Глобальные эталонные показатели

- США: Регулируется методом EPA 25A.

- КитайВ соответствии со стандартами GB 37822-2019, наличие научно-исследовательских лабораторий является обязательным условием для допуска в химический парк.

Практический опыт и примеры успешных проектов

Практический опыт: Урок по устранению засоров

В проекте в Северный БрабантВ течение трех месяцев мы наблюдали резкое падение давления.

- ПроблемаСледы масляных туманов, образующихся при производстве мягких желатиновых капсул, обугливались на керамической поверхности.

- РешениеМодернизация системы включает установку трехступенчатой системы фильтрации и автоматического цикла прогрева.

- УрокПредварительная обработка — это «сердце», определяющее срок службы вашего RTO.

Пример из практики: крупная голландская фармацевтическая компания (50 000 $m^3/h$)

- ФонВысокие эксплуатационные расходы из-за использования угольных электростанций и нестабильные выбросы этанола.

- Решение: 3-башенная система RTO + вторичное рекуперирование энергии.

- РезультатыУровень DRE стабилизировался на отметке 99,51 TP3T; превышена годовая экономия природного газа. €120,000.

Тенденции будущего: следующее поколение региональных транспортных организаций

- Реакторная термическая обработка (RTO) + улавливание углерода (CCUS): Улавливание чистого $CO_2$ для использования в голландских теплицах.

- Водородные горелкиПереход к вспомогательным видам топлива с нулевым выбросом углерода.

- Техническое обслуживание ИИИспользование машинного обучения для прогнозирования колебаний нагрузки и оптимизации циклов работы клапанов.

ЗаключениеДля голландских и международных фармацевтических предприятий: высокоспециализированный продукт. РТО Это не просто экологические издержки, это стратегический актив для достижения цели создания «зеленой фабрики».