在创新与可持续发展交融的荷兰中心地带,卷材涂装行业蓬勃发展,成为制造业的基石。从点缀阿姆斯特丹现代天际线的建筑面板,到埃因霍温高科技中心生产的汽车零部件,卷材涂装工艺都要求精准高效且兼顾环保。荷兰工业以其对绿色实践和循环经济原则的坚持而闻名,但在管理这些生产过程中产生的排放方面,却面临着独特的挑战。涂装和干燥阶段释放的挥发性有机化合物(VOCs)需要强有力的解决方案,以满足荷兰严格的空气质量目标。荷兰人口稠密,且毗邻瓦登海等自然保护区,这些目标都受到荷兰空气质量目标的制约。

我们的RTO系统处于这一领域的前沿,专为满足荷兰市场对能源效率和环境影响最小化的重视而设计。凭借数十年来处理大规模排放的经验,这些系统能够无缝集成到北荷兰省和南荷兰省等大型涂装工厂的生产线中。它们不仅能消除有害污染物,还能回收热量以降低运营成本,这体现了荷兰在历史上的风车和现代可持续建筑中体现的巧妙工程传统。

除了荷兰之外,德国、比利时和法国等邻国也拥有类似的工业格局,杜塞尔多夫和布鲁塞尔等城市都有卷材涂装中心。在全球范围内,包括美国(在俄亥俄州和密歇根州等州设有工厂)、中国(上海和广东省)、日本(东京和大阪)、韩国(首尔和釜山)、意大利(米兰和都灵)、西班牙(巴塞罗那和马德里)、英国(伦敦和伯明翰)、加拿大(多伦多和蒙特利尔)、澳大利亚(悉尼和墨尔本)、巴西(圣保罗和里约热内卢)、印度(孟买和德里)、墨西哥(墨西哥城和蒙特雷)、土耳其(伊斯坦布尔和安卡拉)、波兰(华沙和克拉科夫)、瑞典(斯德哥尔摩和哥德堡)、挪威(奥斯陆和卑尔根)、丹麦(哥本哈根和奥胡斯)、芬兰(赫尔辛基和坦佩雷)、瑞士(苏黎世和日内瓦)、奥地利(维也纳和格拉茨)、捷克(布拉格和布尔诺)、葡萄牙(里斯本和波尔图)、爱尔兰(都柏林和科克)、希腊(雅典和圣保罗)在内的主要国家均设有工厂。塞萨洛尼基)、南非(约翰内斯堡和开普敦)、沙特阿拉伯(利雅得和吉达)、阿拉伯联合酋长国(迪拜和阿布扎比)、印度尼西亚(雅加达和泗水)以及越南(胡志明市和河内)都优先采用先进的RTO技术来控制卷材涂料中的VOC,以适应当地的法规和行业特点。

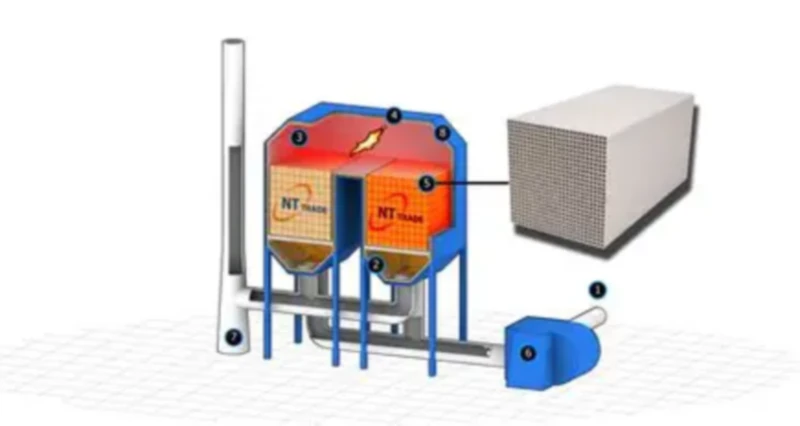

该图展示了鹿特丹一条典型的卷材涂装生产线,重点展示了金属卷材连续进料通过清洗、底涂和面涂站的过程,在此过程中会产生排放物并被收集起来进行 RTO 处理。

了解荷兰背景下的卷材涂层工艺和排放挑战

卷材涂装,也称预涂装,是指在将连续金属带材加工成最终产品之前,先对其施加保护性和装饰性涂层。在荷兰,该行业为乌得勒支的建筑业和海尔德兰省的交通运输业等行业提供支持,在这些行业中,铝卷和钢卷需要进行底漆、面漆和背衬处理。该工艺包括脱脂、化学预处理、通过辊涂机进行涂层涂覆,以及在烘箱中固化,固化温度通常高达 250°C。

主要排放源来自含有芳烃(如二甲苯和甲苯)以及酯类(如乙酸丁酯)的溶剂型涂料。这些挥发性有机化合物(VOCs)在干燥过程中挥发,产生浓度为2-10 g/Nm³、单条生产线排放量高达150,000 m³/h的废气。位于林堡省和上艾瑟尔省等荷兰省份的工厂必须解决这些问题,以符合国家空气质量指令的要求。这些指令强调低排放,旨在保护海牙等城市地区的空气质量。

荷兰地势平坦,海洋性气候加剧了废气扩散问题,因此局部解决方案至关重要。邻近的比利时弗兰德斯地区和德国北莱茵-威斯特法伦州也拥有类似的潮湿气候,导致废气湿度可达30-60%。在全球范围内,像中国沿海城市(例如广东)或巴西(例如里约热内卢)这样的潮湿气候地区也面临着类似的挑战,需要具备强大除湿能力的RTO系统。

通过对荷兰工厂的实地考察,我们发现,排放控制不当会导致附近社区投诉异味,进而影响工厂运营。北布拉班特省的一个案例是,工厂升级到RTO系统后,VOC(挥发性有机化合物)排放量减少了98%,不仅改善了与社区的关系,也使得工厂得以继续扩张。

该视频演示了阿姆斯特丹附近一家卷材涂层厂的 RTO 系统运行情况,展示了气体流经预热室、燃烧和热回收的过程,并着重强调了实时节能。

专为荷兰卷材涂装作业量身定制的RTO系统的主要特点

RTO技术在处理卷材涂装生产线产生的稳定、中等浓度排放方面表现出色。在能源成本高昂、高度依赖天然气的荷兰,我们的系统热效率高达95-97%,可回收余热用于烘箱预热或蒸汽产生,符合荷兰的可持续发展倡议,例如《可持续增长能源协议》。

其独特之处在于采用多腔室设计(最多可达 18 个床层),并配备旋转阀以实现平稳的流量切换,从而最大限度地减少可能影响涂层均匀性的压力波动。此外,还采用耐腐蚀合金等材料,可耐受芳香族溶剂,确保在潮湿的荷兰环境中拥有长久的使用寿命。

对于像弗里斯兰省和泽兰省这样受沿海气候影响的省份,系统会采用增强型隔热措施来防止冷凝。在全球范围内,在加州湾区或日本关西地区的类似系统中,这些改进措施都能有效避免停机。

该图分解了 RTO 组件,说明了废气如何预热、在 850°C 下氧化以及回收热量,专为荷兰线圈涂层效率而设计。

一位工程师分享了来自海尔德兰省一家工厂的故事:“改用这种 RTO 后,我们的燃料消耗量减少了 40%,而且自动化控制使维护变得简单,完美契合了我们精益运营的理念。”

技术参数:28 项实现最佳性能的关键规格

| 范围 | 值/范围 | 描述 |

|---|---|---|

| 热效率 | 95-97% | 从废气中回收热量,降低荷兰高成本运营的能源投入。 |

| VOC去除效率 | >98% | VOCs氧化成CO2和H2O的百分比,符合荷兰严格的限制标准。 |

| 气流容量 | 50,000-150,000立方米/小时 | 处理北布拉班特省各工厂典型的卷材涂装生产线产量。 |

| 工作温度 | 800-900°C | 燃烧室加热可使VOC完全分解。 |

| 压降 | <300 帕 | 在潮湿环境下保持工艺流程顺畅所需的最小阻力。 |

| 停留时间 | 0.5-1.0秒 | 气体在燃烧区停留的时间,以进行彻底氧化。 |

| 热回收介质 | 结构陶瓷 | 高表面积材料,传热效率高。 |

| 阀门切换周期 | 60-120秒 | 多床系统中流向变化的频率。 |

| 泄漏率 | <0.1% | 未经处理的气体旁路量极少,确保合规性。 |

| 燃料类型 | 天然气/液化石油气 | 与荷兰能源基础设施兼容。 |

| 功耗 | 10-50千瓦 | 风扇和控制装置的电力需求低。 |

| 脚印 | 10-20平方米 | 紧凑型设计,适用于空间受限的荷兰工厂。 |

| 建筑材料 | 316不锈钢 | 耐溶剂腐蚀。 |

| 噪音水平 | 小于 85 分贝 | 适用于鹿特丹等城市地区的静音运行。 |

| 维护周期 | 每6个月 | 阀门和介质的定期检查。 |

| 启动时间 | 30-60分钟 | 快速升温至工作温度。 |

| 转弯率 | 5:1 | 能够灵活适应不同的生产负荷。 |

| 排气温度 | 100-150°C | 恢复后气体温度。 |

| 控制系统 | PLC与HMI | 自动监测和调整。 |

| 安全联锁装置 | LEL监测 | 防止浓度过高而引发爆炸。 |

| 热交换器类型 | 再生 | 为了最大限度地回收能量。 |

| 重量 | 5-15吨 | 取决于产能。 |

| 寿命 | 15-20年 | 只要保养得当。 |

| 安装时间 | 4-6周 | 现场组装。 |

| 合规标准 | 欧盟IED,荷兰NEa | 符合当地和国际法规。 |

| 节能 | 最高可达 80% | 与直接焚烧相比。 |

| 减少二氧化碳排放 | 50-70% | 通过提高效率。 |

| 远程监控 | 是的,支持物联网 | 用于实时数据访问。 |

这些参数确保了荷兰卷材涂装设备的可靠性,而精度在其中至关重要。

荷兰及其他地区的环境法规与合规

荷兰根据《活动法令》(Activiteitenbesluit)实施严格的标准,将卷材涂装的挥发性有机化合物(VOC)排放量限制在50毫克/立方米以内。在乌得勒支等省份,地方许可证要求进行持续监测,这与欧盟《工业排放指令》(IED)相一致,该指令要求采用最佳可行技术(BAT)来减少VOC排放(>95%)。违规者每次违规最高可被处以10万欧元的罚款。

邻国德国遵循TA Luft法规,在巴伐利亚等工业区,挥发性有机化合物(VOCs)的限值低至20毫克/标准立方米。比利时弗兰德斯地区的VLAREM II法规则强调气味控制和VOCs控制。法国在法兰西岛等地区实施的ICPE法规要求大型设施进行实时检测(RTO)。

在全球范围内,美国环保署 (EPA) 针对卷材涂料制定的 NESHAP 标准将有害空气污染物 (HAP) 的限值设定为 0.08 磅/加仑,对德克萨斯州等州产生影响。中国江苏省等省份的 GB 37824-2019 标准要求涂料能效达到 95% 以上。日本东京的《空气污染控制法》将苯的浓度目标设定为低于 3 毫克/标准立方米。韩国京畿道的《清洁空气保护法》与欧盟标准相符。意大利伦巴第大区的 D.Lgs 152/2006 号法令侧重于溶剂回收。西班牙加泰罗尼亚的 RD 117/2003 号法令要求采用最佳可行技术 (BAT)。英国英格兰的 EPR 法规将挥发性有机化合物 (VOC) 的浓度限制在 50 毫克/标准立方米。加拿大安大略省的 CCME 指南强调降低氮氧化物 (NOx) 的排放。澳大利亚新南威尔士州的 NEPM 法规设定了环境标准。巴西圣保罗的 CONAMA 430 法规强制要求减少 80% 的排放。印度马哈拉施特拉邦的中央污染控制委员会(CPCB)标准针对涂料排放的PM2.5。墨西哥联邦区的NOM-121法规控制臭氧前体物。土耳其马尔马拉地区的空气质量法规要求进行监测。波兰马佐夫舍省的环境保护法与欧盟标准一致。瑞典斯德哥尔摩的《环境法》推动零排放技术。挪威奥斯陆的《污染控制法》侧重于峡湾保护。丹麦西兰省的《环境保护法》强调可持续性。芬兰乌西玛地区的YSL法规要求获得许可。瑞士苏黎世的LRV法规设定了较低的排放阈值。奥地利下奥地利州的《排放控制法》强制要求提高能效。捷克布拉格的《空气保护法》遵循欧盟标准。葡萄牙北部的DL 127/2013法规要求采用最佳可行技术(BAT)。爱尔兰伦斯特省的《环境保护法》控制溶剂。希腊阿提卡地区的JMD 14122法规以空气质量为目标。南非豪登省的AQA标准限制挥发性有机化合物(VOCs)的排放。沙特阿拉伯东部省的PME标准侧重于石油相关领域。阿联酋阿布扎比的EAD标准要求采用先进技术。印度尼西亚爪哇岛的PERMEN LHK 19/2021标准强制要求减少挥发性有机化合物的排放。越南湄公河三角洲的QCVN 19:2021/BTNMT标准强调合规性。

来自荷兰的案例研究表明,区域运输组织 (RTO) 实现了完全合规,其中南荷兰省的一个 RTO 将排放量减少到 20 mg/Nm³ 以下,避免了处罚。

该图表将荷兰格罗宁根省和德伦特省等省份的排放限值与全球标准进行了比较,显示了 RTO 如何超越要求。

品牌比较:在竞争格局中的定位

在评估荷兰卷材涂装的RTO(快速热处理)方案时,与知名品牌进行比较可以提供宝贵的参考信息。仅供技术参考,作为一家独立制造商,EVER-POWER提供的系统在关键领域的性能可与知名品牌媲美甚至超越。

与以高端汽车集成解决方案著称的杜尔™ (Dürr™) 相比,我们的 RTO 拥有类似的 97% 热效率,但针对荷兰的湿度进行了定制化调整,且潜在投资成本更低。安格尔™ (Anguil™) 擅长模块化设计;我们的方案强调旋转阀,以确保在类似泽兰省的连续生产线中运行更加平稳。

(注:所有制造商名称和零件编号仅供参考。EVER-POWER是一家独立制造商。)

在全球范围内,例如美国中西部工厂或中国长江三角洲工厂,我们的系统具有很强的耐用性,用户反馈表明,与某些替代方案相比,我们的系统更容易维护。

确保长期可靠性的关键部件、备件和耗材

用于盘管涂层的RTO系统包含一些关键部件,例如用于储热的陶瓷介质床、用于气体切换的提升阀或旋转阀以及用于辅助加热的燃烧器。阀门密封件(每6-12个月更换一次)和陶瓷鞍座(每年检查一次)等易耗件可确保系统正常运行。

传动部件包括阀门和风扇的驱动电机,其轴承需要每季度润滑一次。备件包包含热电偶、压力传感器和阻火器。在荷兰的系统中,耐腐蚀风扇用于处理含溶剂气体;而在邻国比利时,类似的部件则能适应不同的负载。

在全球范围内,在印度沿海各邦或澳大利亚昆士兰等高湿度地区,这些部件对于防止故障至关重要。

该爆炸图详细展示了 RTO 部件,有助于荷兰工厂进行维护计划。

卷材涂装的实际应用和用户体验

在荷兰北部一家生产建筑用卷材的工厂,我们的RTO系统处理量为10万立方米/小时,减少了991吨挥发性有机化合物(VOCs)的排放,并回收热量用于干燥炉,每年节省5万欧元的能源成本。工厂经理指出:“该系统在生产高峰期的稳定性令人印象深刻,完美契合我们全天候24小时运转的模式。”

在海尔德兰省也取得了类似的成功,这得益于与现有生产线的整合,使得排放量低于荷兰的标准,从而提高了对德国的出口合规性。亲自参与安装工作后,我发现自动化诊断系统能够有效防止停机,而停机在潮湿气候下是一个常见问题。

在国际上,加州中央谷地的一个案例展现了荷兰的高效模式,而上海工业园区的案例则证明,针对更高产量进行的调整行之有效。这些经验凸显了跨国界适应能力的重要性。

这张案例研究照片捕捉了埃因霍温的一个 RTO 装置,并叠加了排放减少的数据。

这张地图显示了 RTO 在主要地点的部署情况,从阿姆斯特丹到底特律和北京等国际地点。

荷兰卷材涂层RTO应用领域的最新进展

近期新闻报道了多项进展:据荷兰环境新闻报道,2025年,鹿特丹一家卷材涂装厂采用了升级后的RTO(实时氧化处理装置),在新欧盟指令的背景下,实现了98%的VOC(挥发性有机化合物)减排。另据行业期刊TNO Reports报道,乌得勒支另一家涂装厂集成了人工智能监控系统,减少了30%的维护工作。

德国邻近的鲁尔区也进行了类似的升级改造,杜塞尔多夫一家工厂的节能效果达到20%。据美国环保署(EPA)最新数据显示,美国俄亥俄州一家中西部工厂也进行了类似的改造;而中国广东省则实施了更严格的能源标准,促使区域输电系统(RTO)得到广泛应用,正如《南华早报》报道的那样。

联系我们的团队,获取定制方案。 恢复运营 助力您成功的蓝图。